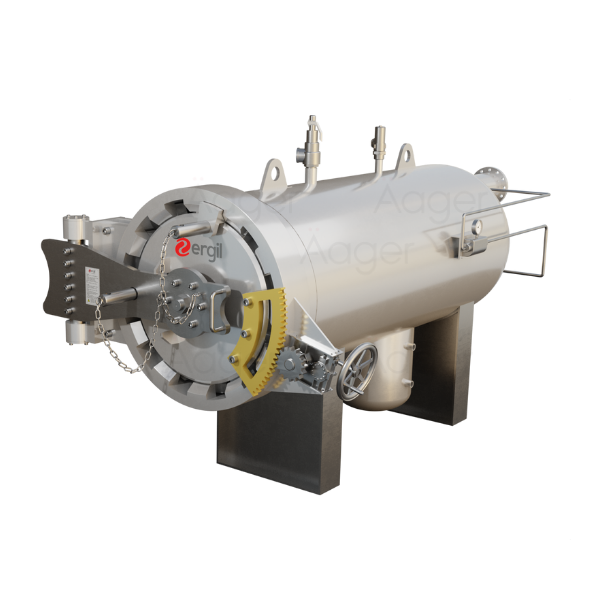

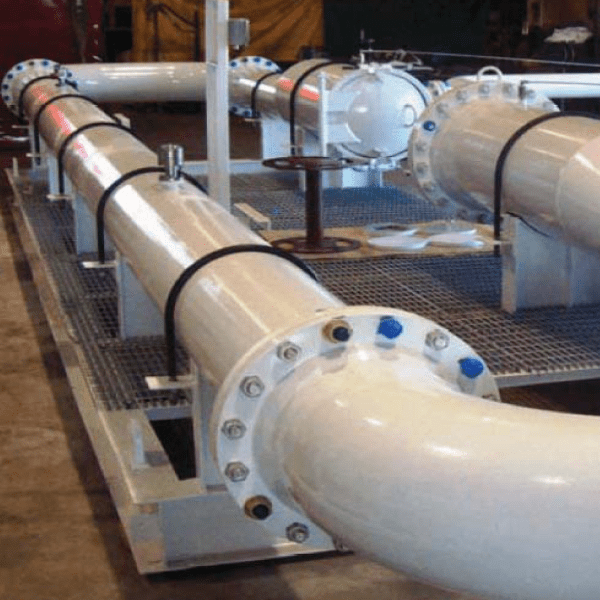

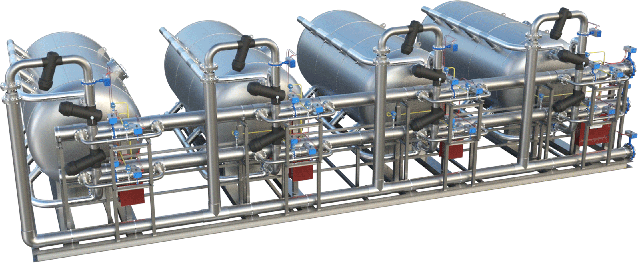

Seperator & Filter Vessels

Products

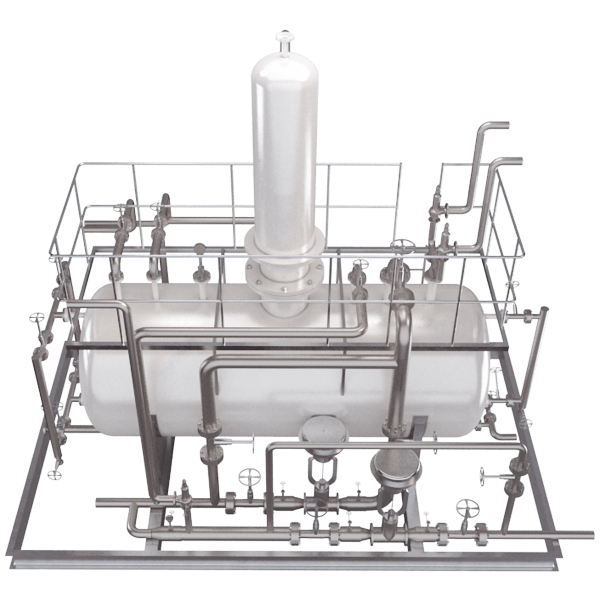

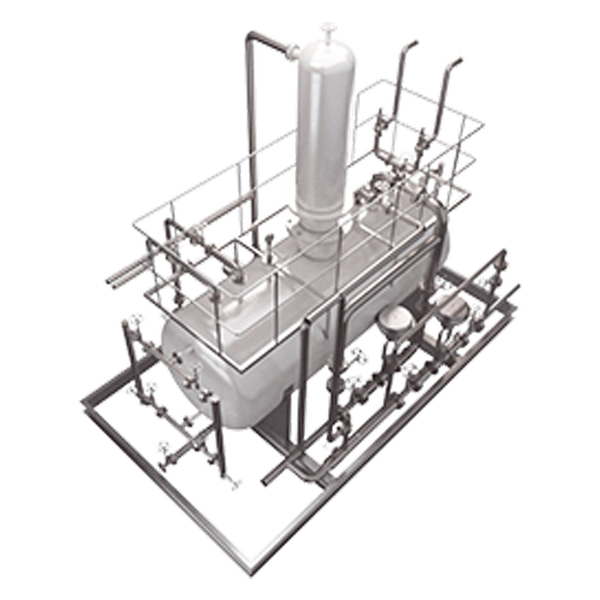

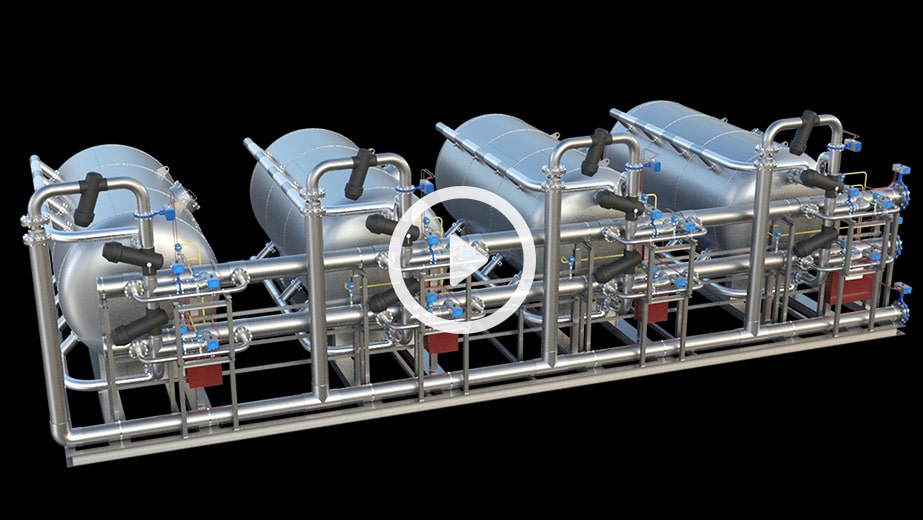

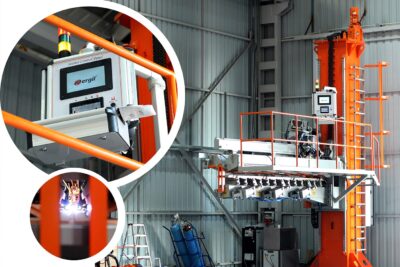

ERGIL provides custom-made turn-key modular process skid systems for any project.

As a single source for plug and play systems, ERGIL can reduce your project cost and time drastically. ERGIL is a specialist designer and manufacturer with extensive experience providing technically advanced process equipment to industry sectors including oil & gas, petrochemical, chemical, pharmaceutical, agro, wastewater treatment, utilities and mining.

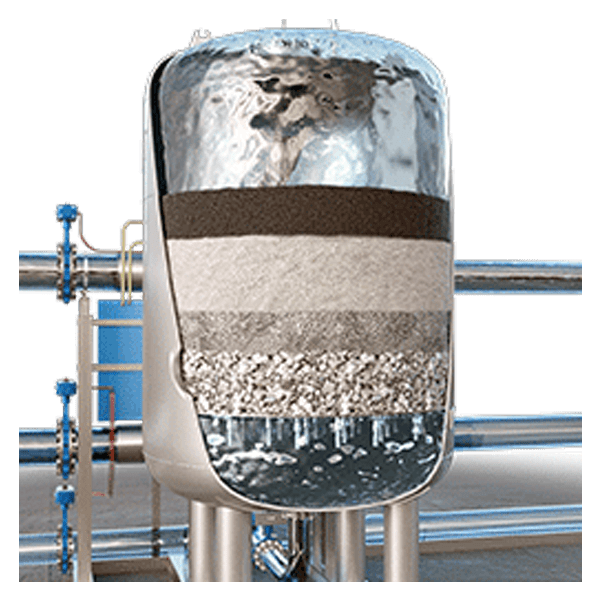

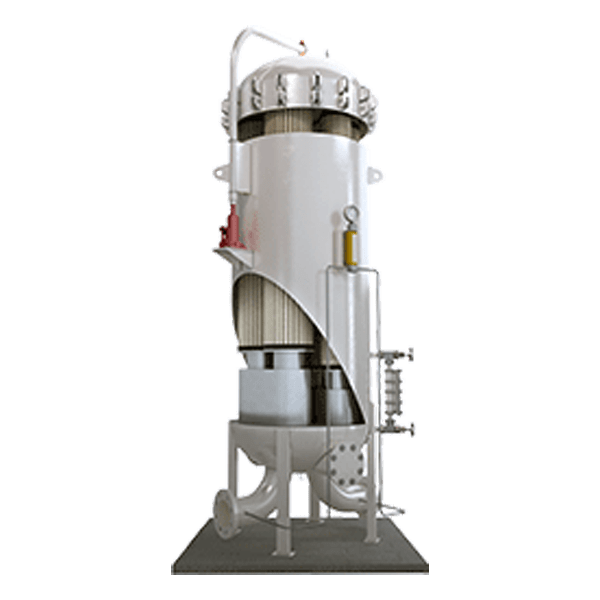

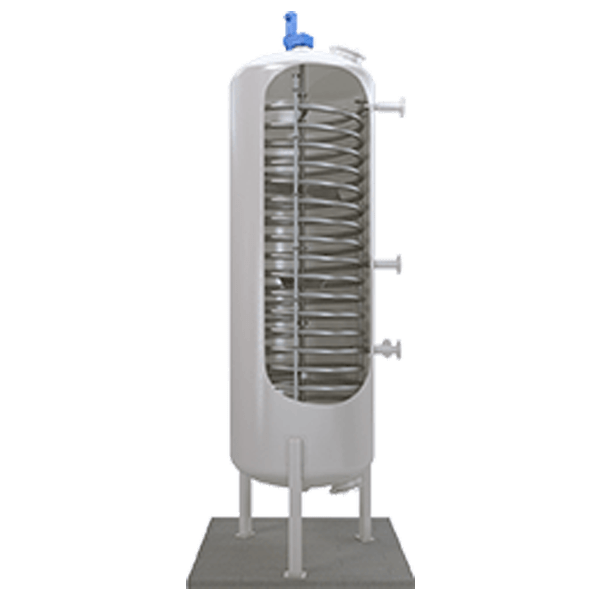

Seperator & Filter Vessels Models

Performance Driven Process Equipment

Designed to separate production fluids into their constituent components of oil, gas and water. Oil and Gas Separator is a pressure vessel used for separating well stream into gaseous and liquid components. They are normally installed on a onshore processing station or on Offshore platform like near the wellhead, manifold, or tank battery

Request A Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon