Filters & Coalescer

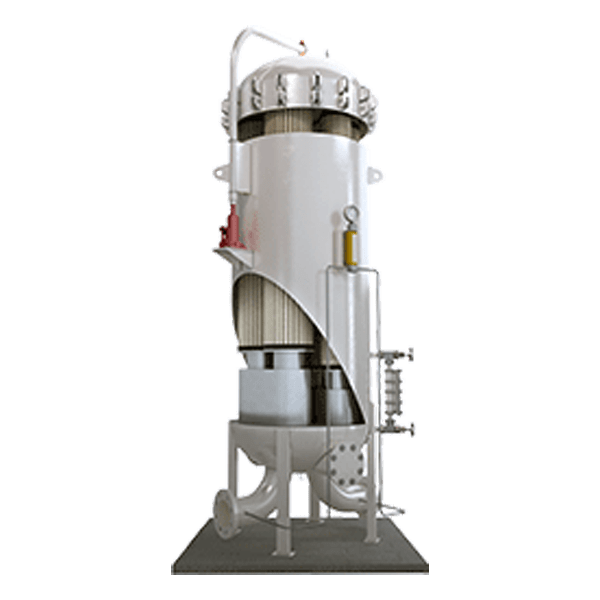

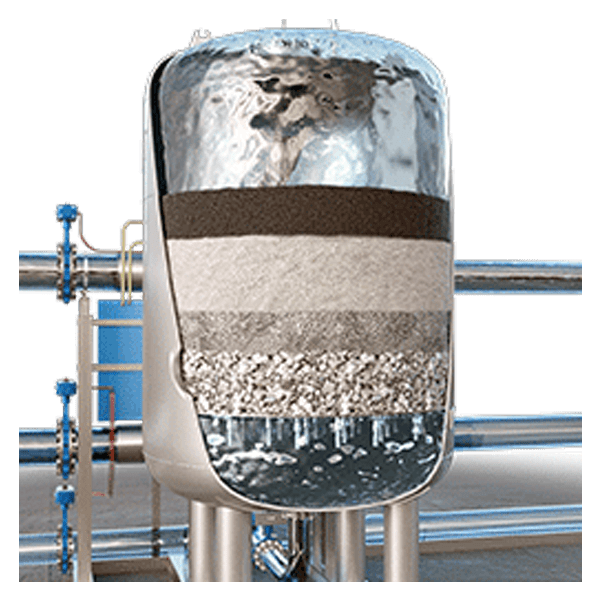

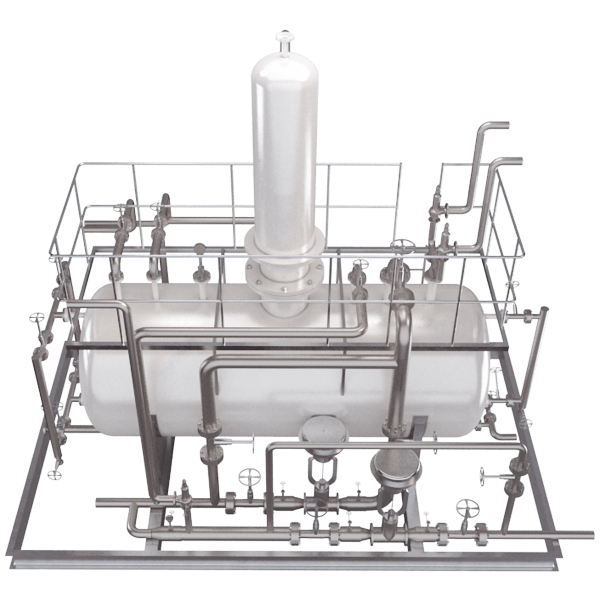

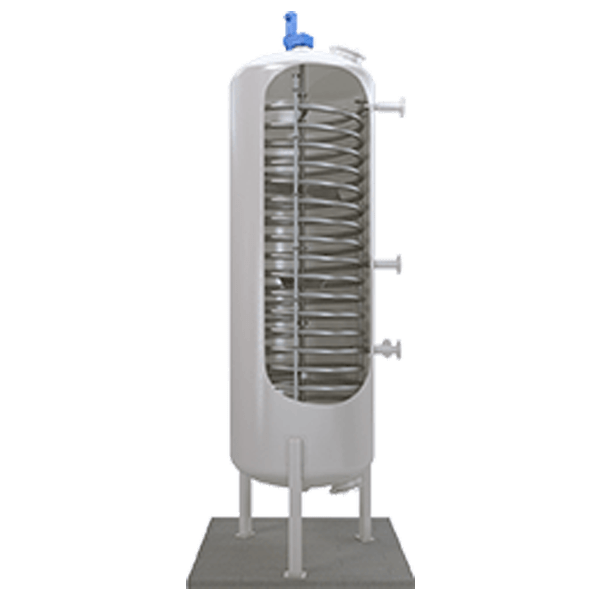

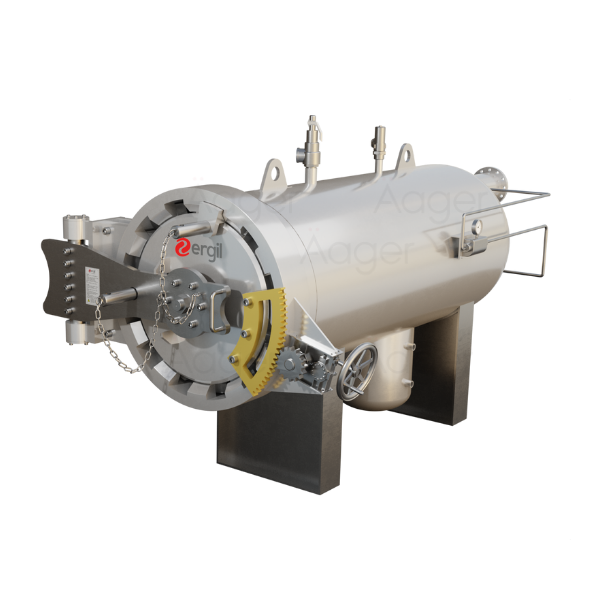

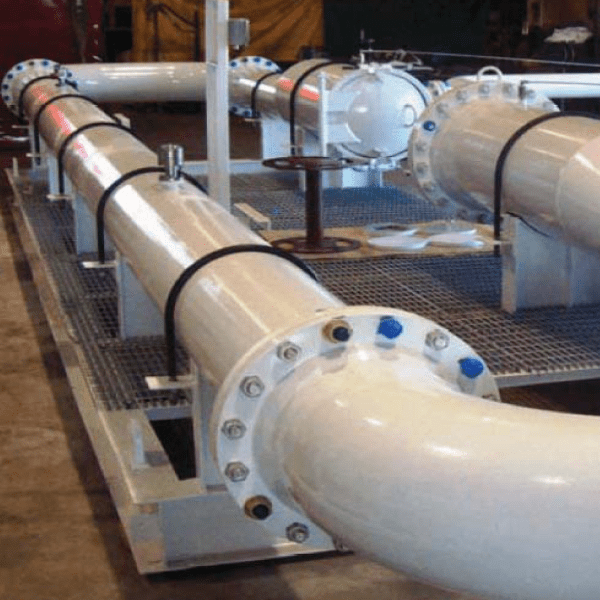

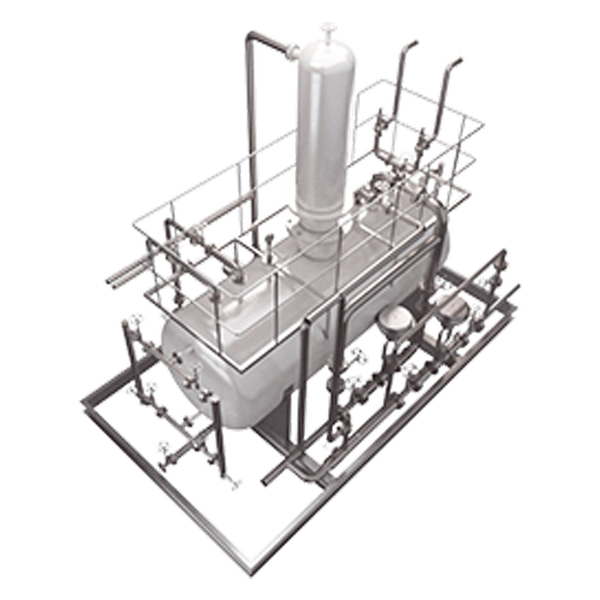

A coalescer filter/water separator is a pressure vessel utilized for clean stream by removing particles as well as separating them into liquid/gas components. Vessel configurations can be divided into horizontal or vertical separators. The separators can be grouped into three-phase coalescer/filter separators and are normally designed in stages that are used for priliminary phase separation for small particiules (down to <1µm). The second and third stages are designed to separate liquid formations from each other by coalescing and separating.

The oil/gas/water separator in petroleum terminology refers to a pressure vessel used to increase purity levels of the fluids especialy gas and jet. The need for a coalescer filter/water separator comes from the industry to clean and produce refined streams for engine systems.

Depending on a specific application, oil/gas separators are basket filters, micro filters, coalescer filters, and separation filters located in different sections. The coalescers are designed to remove liquid droplets into the oil stream by utilizing specially designed filters per the as per requirements of contents to be separated. The system meets the industrial standards and purity levels required for commercial airlines and oil companies.

Parts

| Housing | for Filter Catridges |

| Basket Filters | 400 mesh (23µm) |

| Microfilters | > 1 µm |

| Coalescer filters | designed to separate oil and water |

| Separator filters | restrict water flow through filters |

Advantages

- EPC work completions.

- Engineering submittals and performance guarantee.

- In-house engineering support for all disciplines.

- Check and improve your operational efficiency by simulating control philosophy electronically.

- Provides training, spare parts, and guarantees for the safe operation of our equipment.

- Construction Supervising services.

- Repairing and revision work at the site for stamped vessels.

- Performance monitoring and adjustment activities after commissioning works.

- Skid-mounted modular skids and process units.

- After-sales service available for your ongoing spare parts and mechanical maintenance needs.

- Project management & consulting.

- Logistics & forwarding to site.

- Predictive, preventative maintenance, and operations training.

- Easy installation and maintenance.