Flame Arrestors

Products

Storagetech™ provides the high quality and reliable solution for your need.

Storagetech is an Atex certified designer and manufacturer with extensive experience providing technologically advanced atmospheric storage tank and pipeline safety breather valves, vents and flame arrestors for oil, gas, petrochemical, chemical, pharmaceutical, agro, water, wastewater treatment, and utility industries.

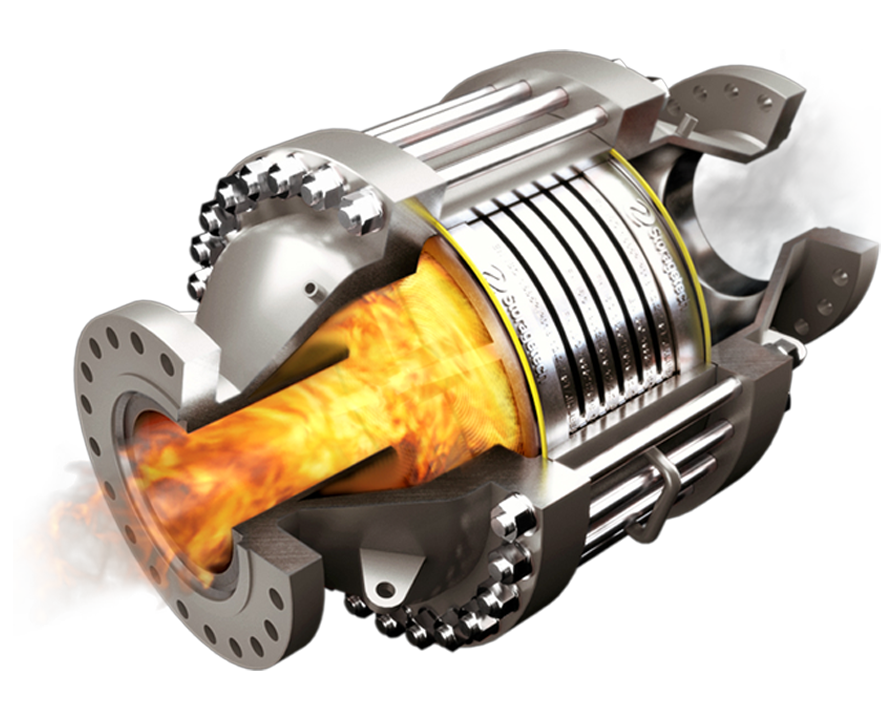

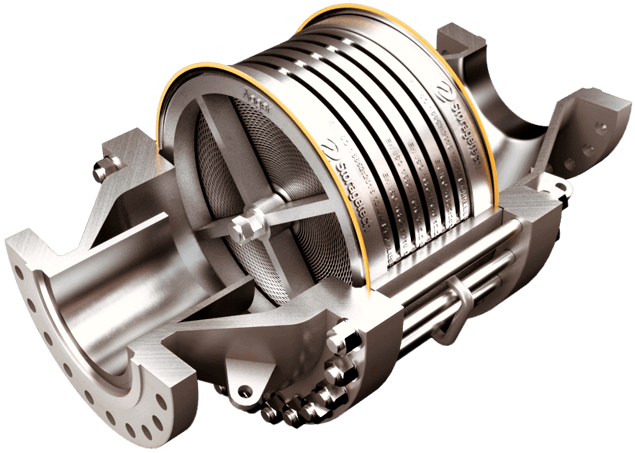

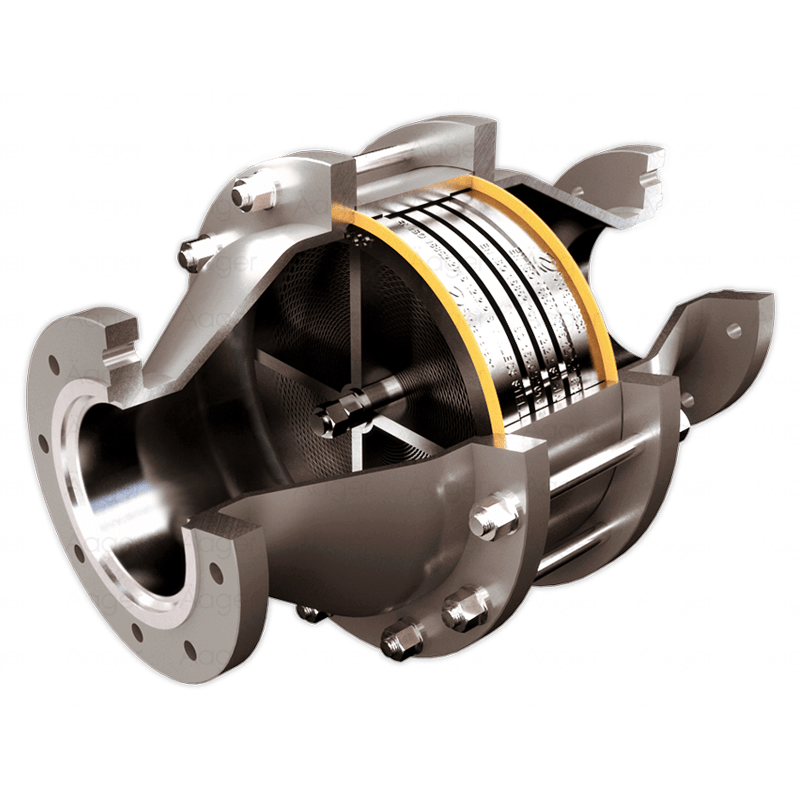

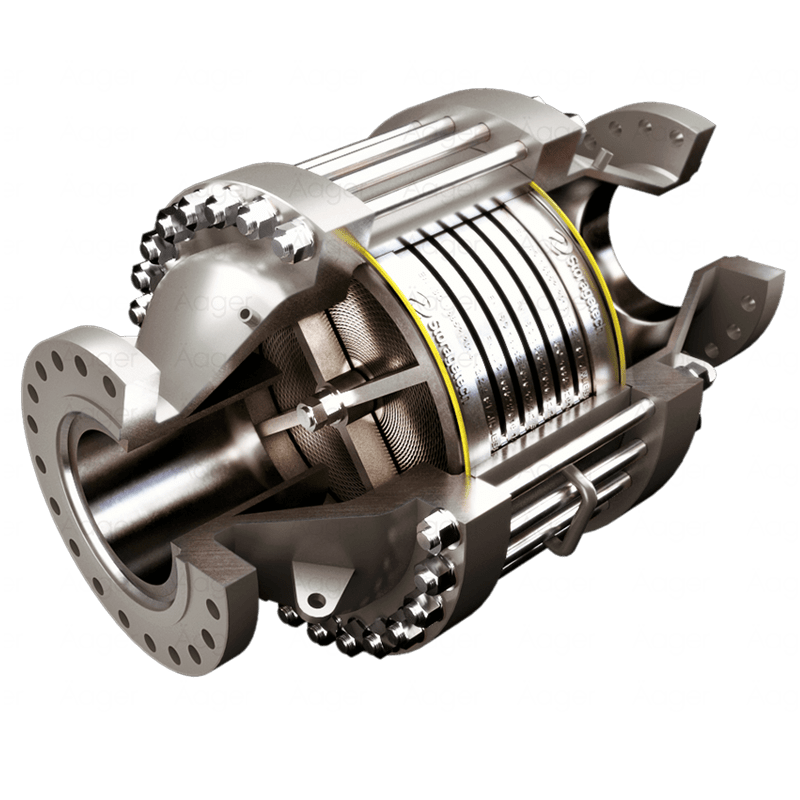

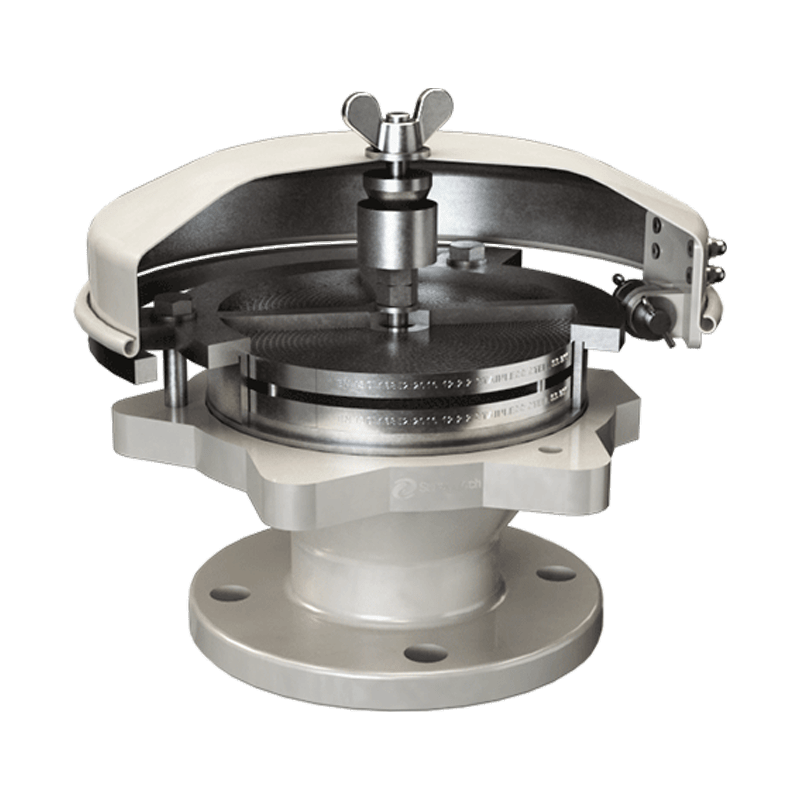

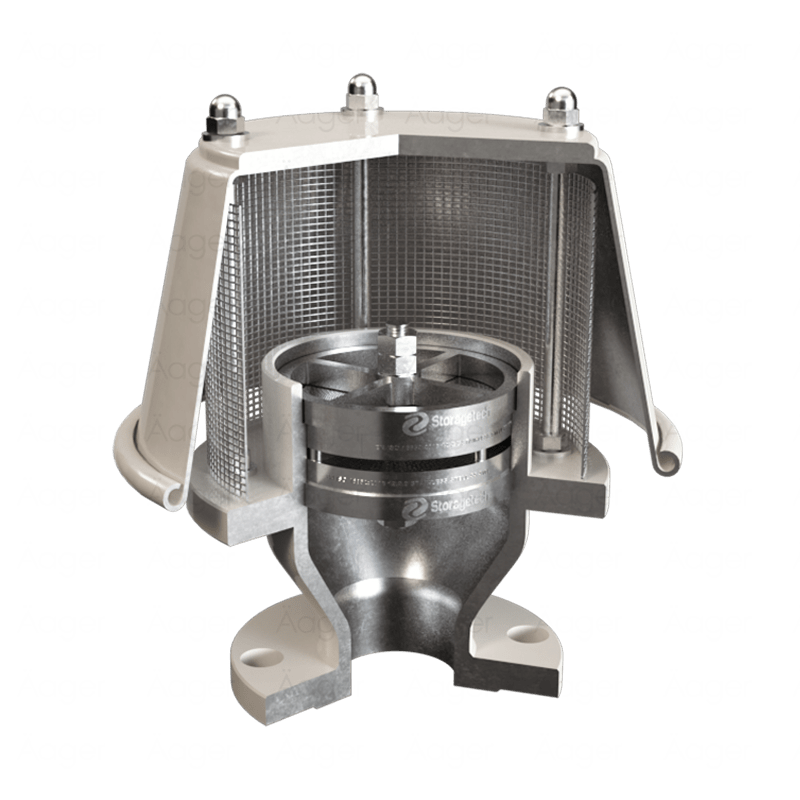

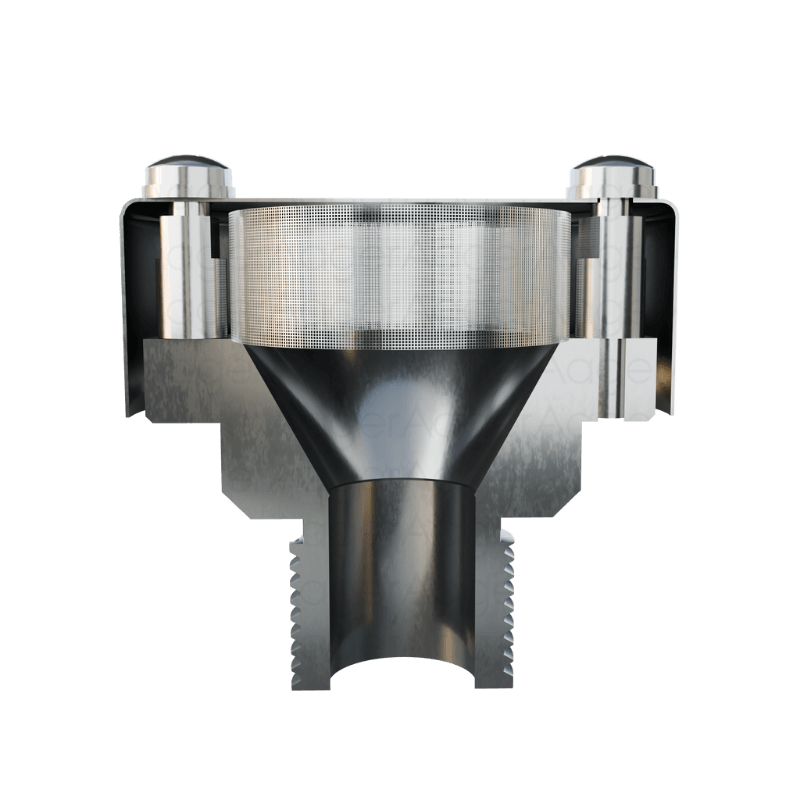

We use high quality flame arrester elements to prevent corrosion and increase the durability of the discs. Reverse winding technology provide better protection by extending the path for flame.

Storagetech™ Flame Arresters have durable and robust design to prevent flame and shock waves which maybe transferred through the pipeline.

All Storagetech™ Flame Arresters are ATEX certified for up to 18’’

Storagetech™ Flame Arresters; design, engineering and tests are carried out according to ASME and EN norms as well as international codes as per client specs.

Flame Arrestors Models

Request A Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon

Storagetech™ Flame Arrester

Crucial Part of Your Pipeline Operation Integrity

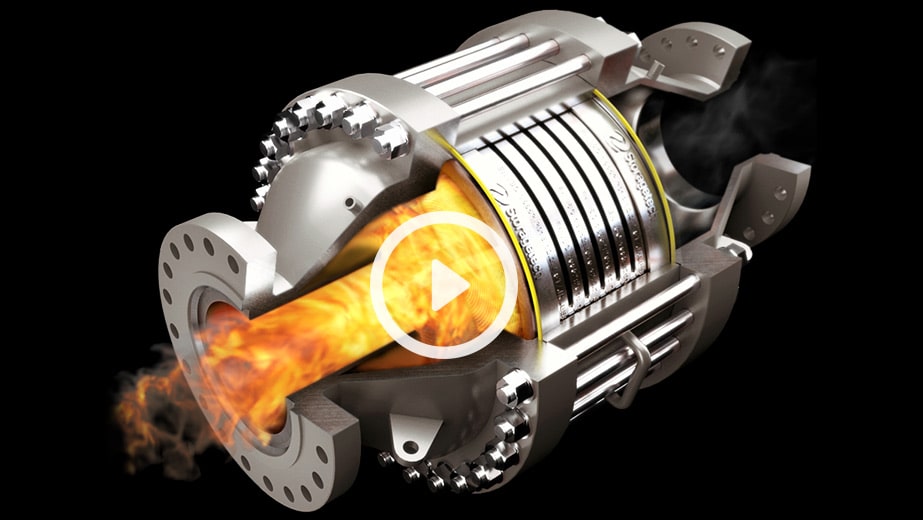

Safe, Reliable and Sustainable Flame Arrester systems are the heart and soul of any pipeline. Storagetech™ Flame Arresters provides ~ 30% less pressure drop compared to ordinary flame arresters with its unique technologies. PTFE coating paint, protects against weather conditions; increases life time, and decreases maintenance cost.They are the crucial part for the operation.

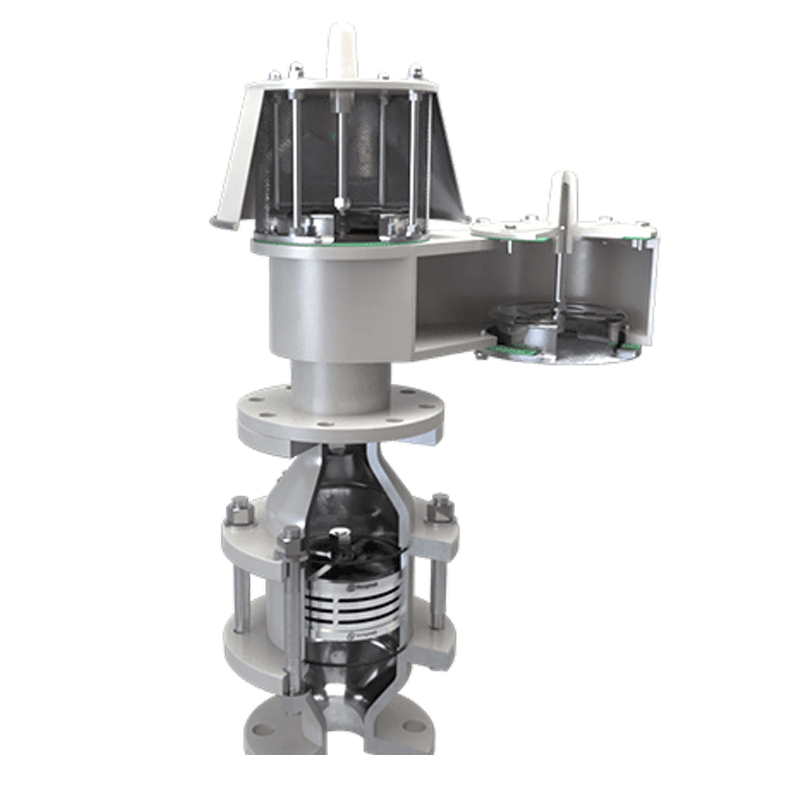

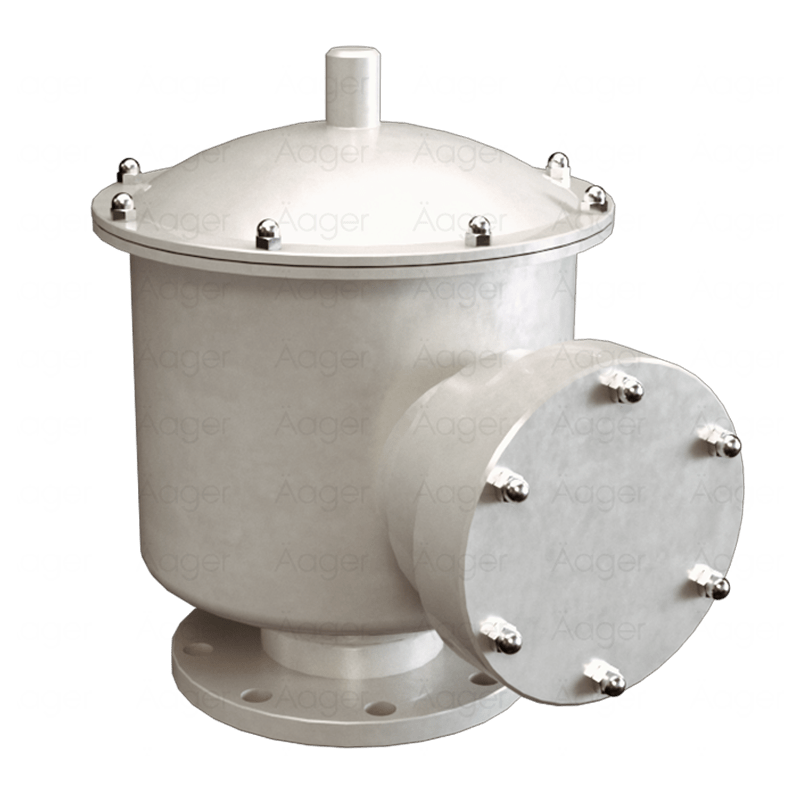

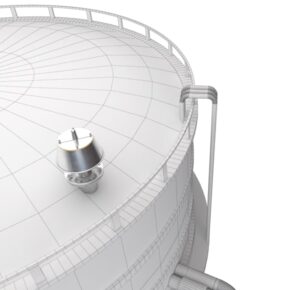

This type of flame arrester is installed on low-pressure storage processing tanks, bleed tanks, or other waste gas devices. Normally, they are installed on a vent nozzle mounted on a tank that is discharged directly into the atmosphere. They can also be incorporated as integral parts of conservation vents installed on atmospheric storage tanks containing flammable liquids. It should be noted that flame arresters are not always necessary as part of conservation vents. The gases produced by vaporization of many flammable liquids have similar flame speeds when mixed with air. Typical of these are gasoline, jet fuel, benzene, plastics monomers, and organic solvents. Often the pressure drop across the vent valve of a conservation vent is a ¾ inch (17mm) of water or more. In this case, the velocity of the gas flow through the vent-valve opening will be higher than the speed at which the flame can propagate upstream through the opening.

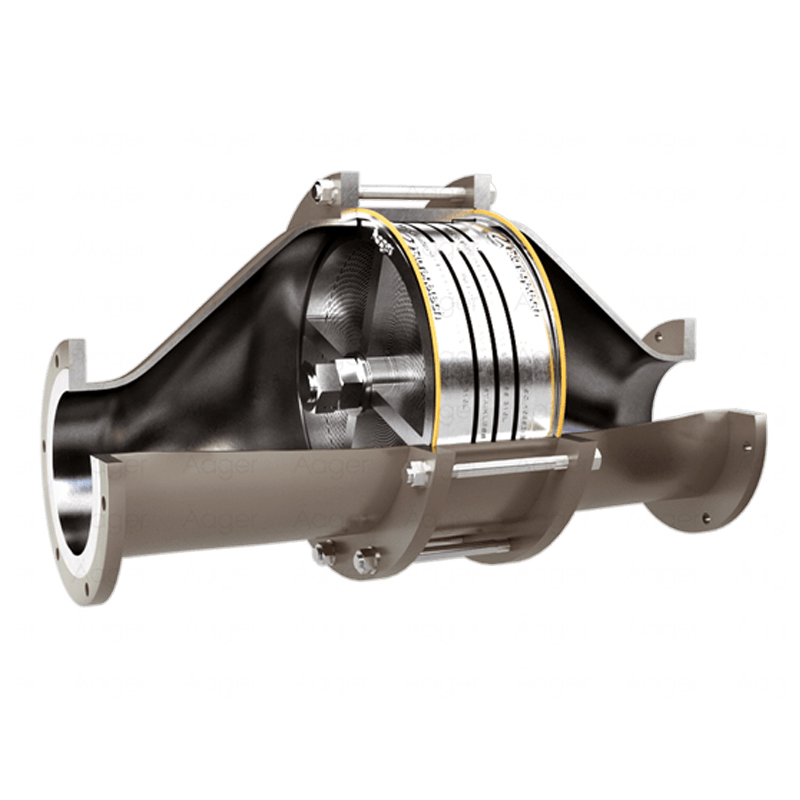

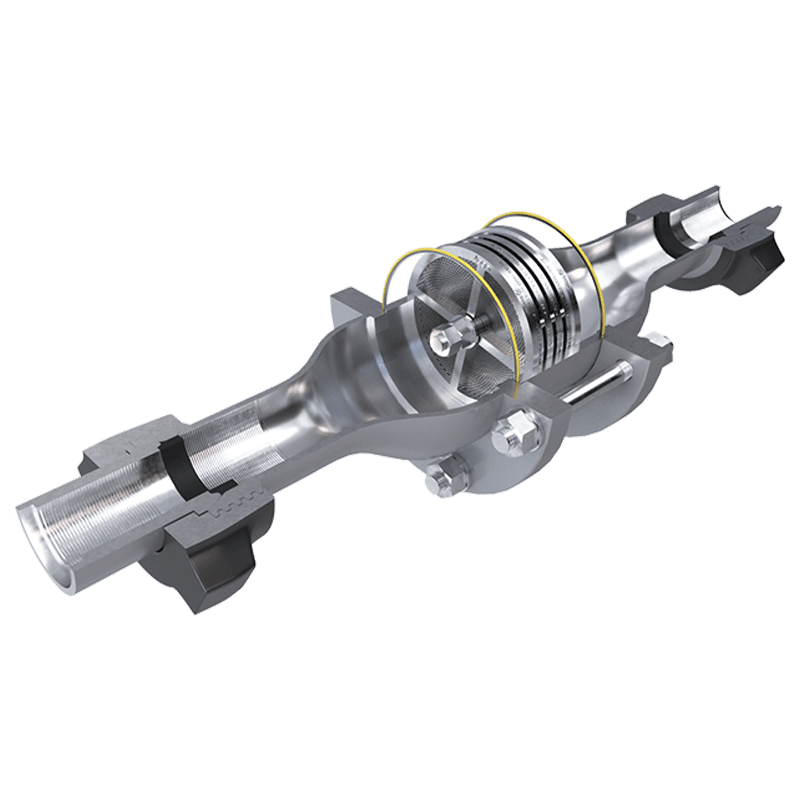

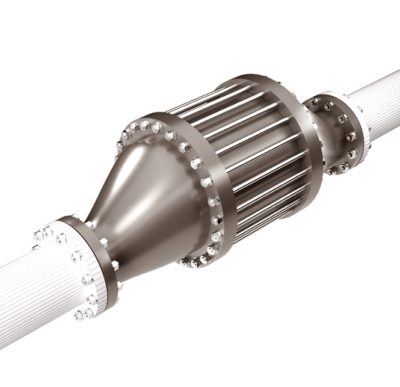

This type of flame arrester is installed on low-pressure storage processing tanks, bleed tanks, or other waste gas devices. Normally, they are installed on a vent nozzle mounted on a tank that is discharged directly into the atmosphere. They can also be incorporated as integral parts of conservation vents installed on atmospheric storage tanks containing flammable liquids. It should be noted that flame arresters are not always necessary as part of conservation vents. The gases produced by vaporization of many flammable liquids have similar flame speeds when mixed with air. Typical of these are gasoline, jet fuel, benzene, plastics monomers, and organic solvents. Often the pressure drop across the vent valve of a conservation vent is a ¾ inch (17mm) of water or more. In this case, the velocity of the gas flow through the vent-valve opening will be higher than the speed at which the flame can propagate upstream through the opening. Sometimes it is desirable to install flame arresters in the middle of a long pipeline. They are particularly suited for installation inside a tank house where vent pipes or lines are extended through the tank house roof or walls to the outside. Locating the unit inside eliminates difficult inspections on the storage tank roof and protects the vent from the freezing of condensate. Combustion in a pipeline can readily make the transition from deflagration than detonation; in the case of some designs, a detonation can be stopped, whereas a deflagration may pass through. Therefore, an in-line flame arrester must withstand and stop both types of combustion from both downstream and upstream in a pipeline. Since the pressures developed in the combustion can be high, the in-line arrester and pipeline must be properly designed, constructed and tested. The flame arrester element itself must be capable of withstanding substantial pressure differentials in both directions as a result of the combustion.

Sometimes it is desirable to install flame arresters in the middle of a long pipeline. They are particularly suited for installation inside a tank house where vent pipes or lines are extended through the tank house roof or walls to the outside. Locating the unit inside eliminates difficult inspections on the storage tank roof and protects the vent from the freezing of condensate. Combustion in a pipeline can readily make the transition from deflagration than detonation; in the case of some designs, a detonation can be stopped, whereas a deflagration may pass through. Therefore, an in-line flame arrester must withstand and stop both types of combustion from both downstream and upstream in a pipeline. Since the pressures developed in the combustion can be high, the in-line arrester and pipeline must be properly designed, constructed and tested. The flame arrester element itself must be capable of withstanding substantial pressure differentials in both directions as a result of the combustion.