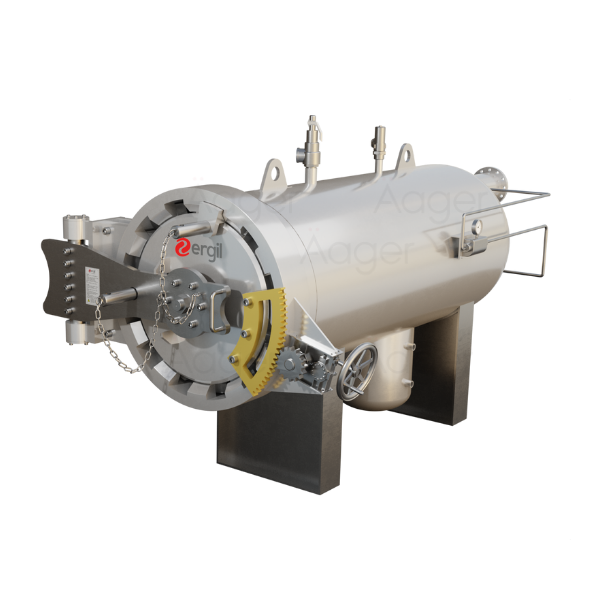

Drain Vessel

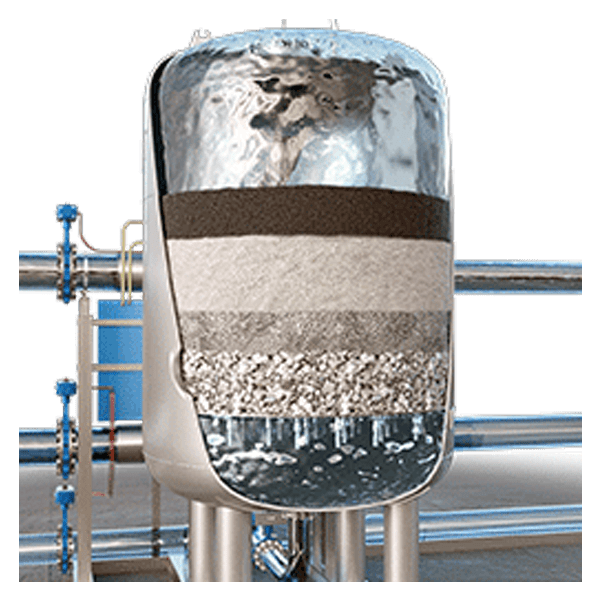

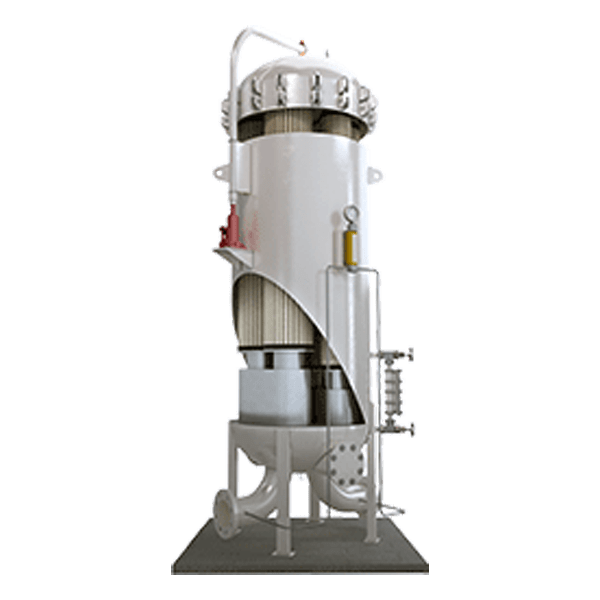

ERGIL drain vessels are designed and manufactured to increase the volume of a coalescing filter housing to hold more liquid and increase the service time. This is mostly useful for negative-pressure applications when an automatic float system failed or cannot be used.

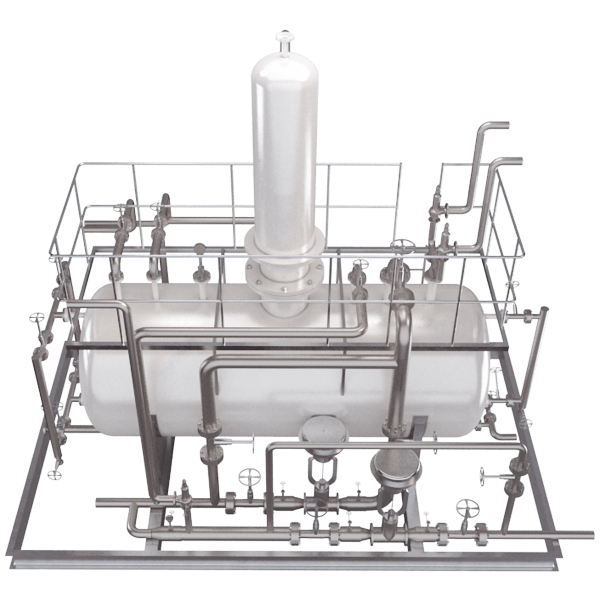

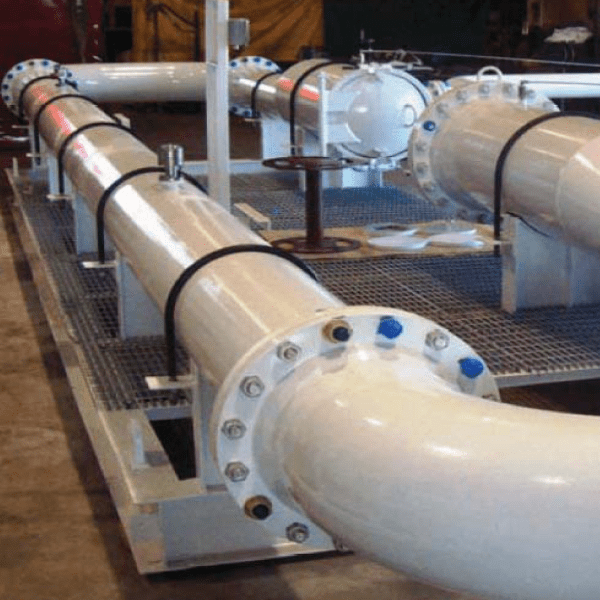

A drain system that is connected directly to pressure vessels is called a “pressure” or “closed” drain system. A drain system that collects liquids that spill on the ground is an “atmospheric,” “gravity,” or “open” drain. The liquid in a closed drain system must be assumed to contain dissolved gases that flash in the drain system and can become a hazard if not handled properly. In addition, it must be assumed that a closed drain valve could be left open by accident. Once the liquid has drained out of the vessel, a large amount of gas will flow out of the vessel into the closed drain system (gas blowby) and will have to be handled safely. Thus, closed drain systems should always be routed to a pressure vessel and should never be connected to an open drain system.

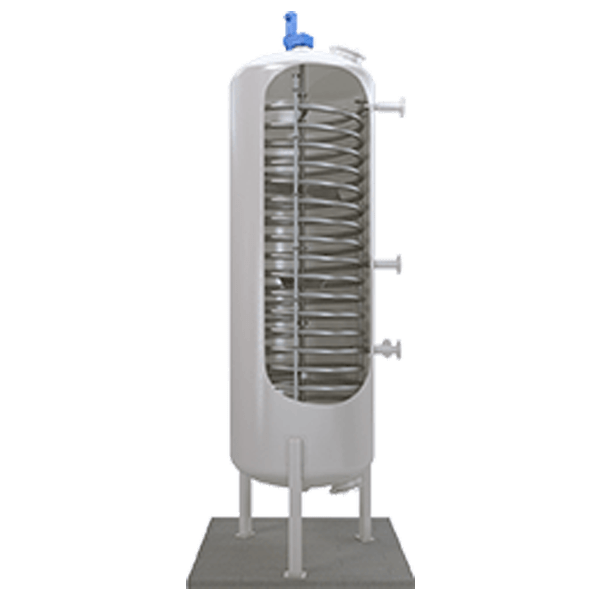

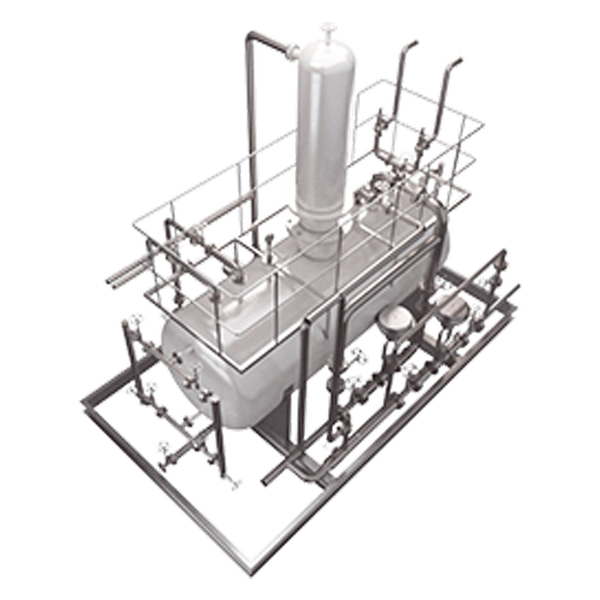

Liquid gathered in an open drain system is typically rainwater or washdown water contaminated with oil. With the oil usually circulated back into the process, every attempt should be made to minimize the amount of aerated water that is recycled with the oil. This goal is best achieved by routing open drains to a sump tank that has a gas blanket and operates as a skimmer. To keep gas from the skimmer from flowing out the drain, a water seal should be built into the inlet to the sump tank. Water seals should also be installed on laterals from separate buildings or enclosures to keep the open drain system from being a conduit of gas from one location in the facility to another.