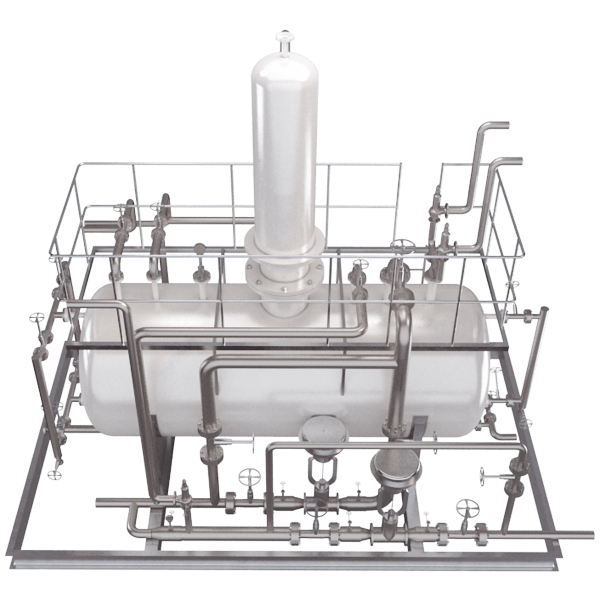

Deaerator Vessels & Feed Water Storage Tanks

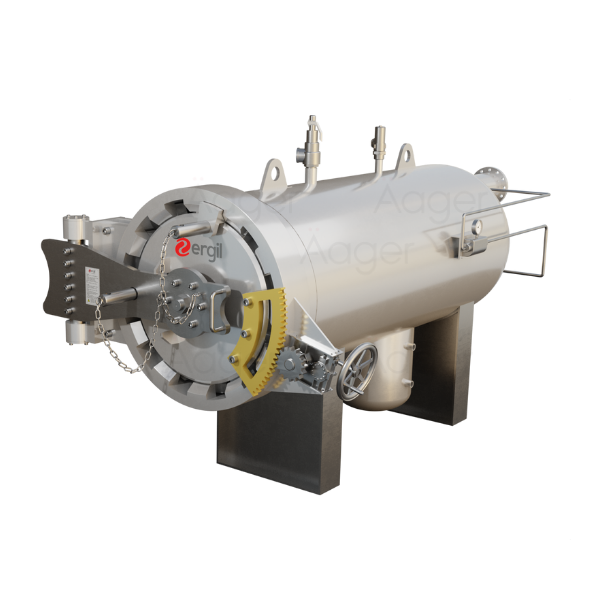

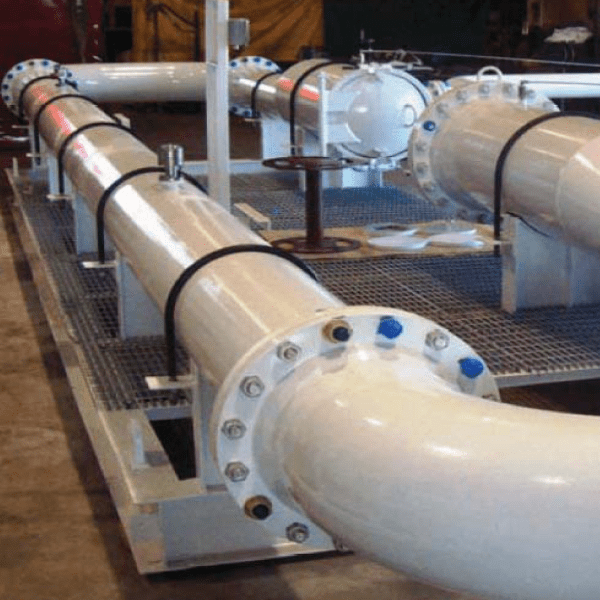

An Äager Brand ERGIL designs, and manufactures two basic types of deaerator which also called deaerator tank, boiler feedwater deaerator or deaerator vessels tray-type and spray-type. These furnished consisting of perforated trays and vent condenser with the internal spray distribution system, storage tank, downcomers, and pressure equalizing piping between the deaerator and feed water.

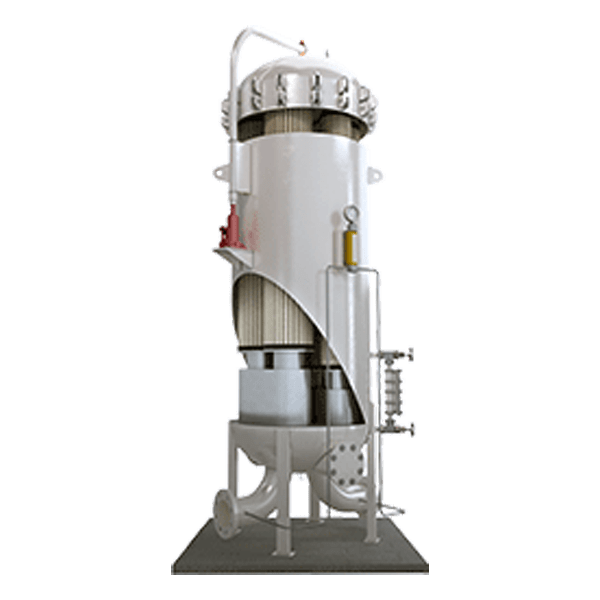

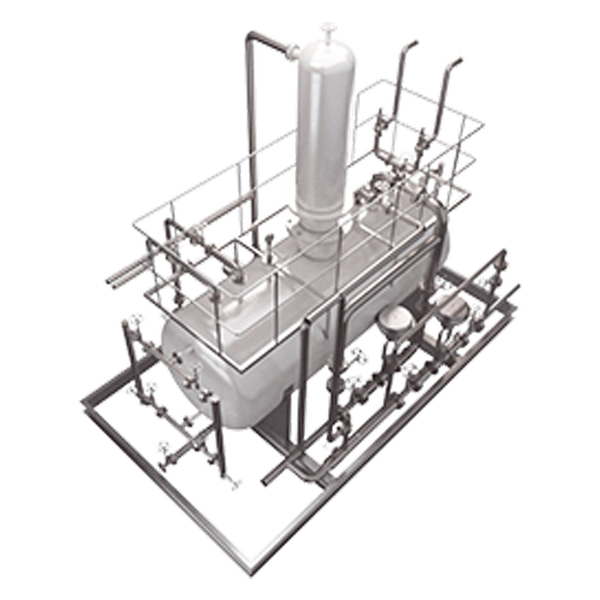

Tray-Type includes a vertical domed deaeration section mounted on top of a horizontal cylindrical vessel. This serves as the deaerated boiler feed removes undissolved oxygen and raises the temperature of the feedwater. The system can be reduced operating costs by recovering flash steam when it is returned by high-temperature condensate. Also, it requires less boiler fuel to convert the feedwater to a usable steam water storage tank.

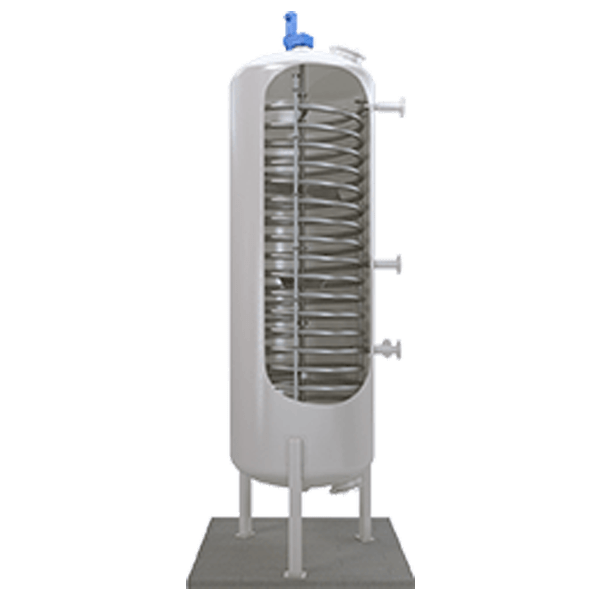

Spray-Type consists only of a horizontal cylindrical vessel that serves as both the deaeration section and the boiler feedwater storage tank. Whether it is a refinery application or a power plant, ERGIL’s deaerators are engineered as per customer specifications.

Pressure relief doors are furnished in the tray enclosure as storage tanks are required.

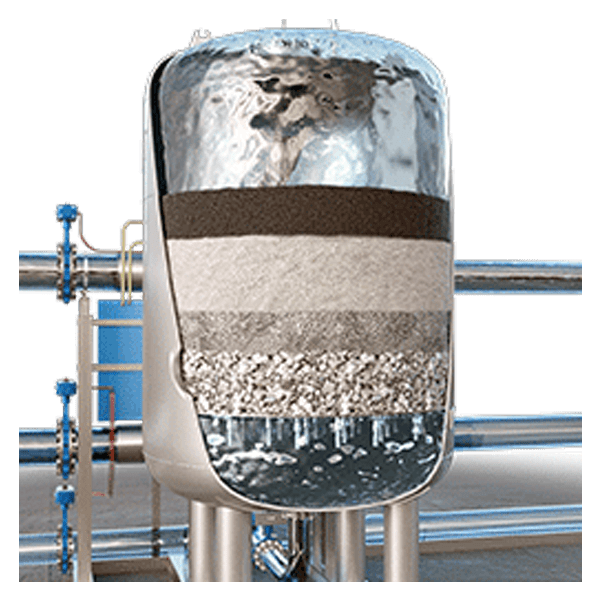

Self-draining perforated trays are provided. These trays are securely fixed in place and deflectors shall

be provided to protect trays from direct impingement of steam and feedwater entering the deaerator and feedwater Storage Tank.

Adequate spacing is provided between inlet fluid connections and deaerating components to prevent damage due to transient conditions, flashing or high velocities.

Features

| Removes undissolved oxygen, |

| Raise the temperature of the feedwater, |

| Operating costs can be reduced by recovering flash steam when returned by high-temperature condensate, |

| Requires less boiler fuel to convert the feedwater to useable steam, |

| Provide water storage capacity and the net positive suction head necessary at the boiler feed pump inlet. |

Technical Specification for Deaerator and Feedwater Storage Tank

- Originator ENKA Identification Number: IQ360-000-3SD-MVR0-00001 Rev. B Date 09-02-2018 Lang. EN Sheet 5/11

- ASME PTC 12.3 Performance Test Code on Deaerators

- ASTM American Society for Testing and Materials

- ASTM A105 Carbon Steel Forgings for Piping Applications

- ASTM A106 Seamless Carbon Steel Pipe for High-Temperature Service

- ASTM A179 Seamless Cold Drawn Low Carbon Steel Heat Exchanger and Condenser Tubes

- ASTM A182/182M Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings and Valves and Parts for High-Temperature Service

- ASTM A216/A216M Steel Castings, Carbon, Suitable for Fusion Welding for High-Temperature Service

- ASTM A333/333M Seamless and Welded Steel Pipe for Low-Temperature Service

- ASTM A350/350M Carbon and Low Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components

- ASTM A515/A515M Pressure Vessel Plates, Carbon Steel for Intermediate and Higher-Temperature Service

- ASTM A516/A516M Pressure Vessel Plates, Carbon Steel for Moderate and Lowe

European Directives

- 97/23/EC Pressure Equipment Directives (PED)

- 98/37/EC Machinery

- 73/23/EEC Low Voltage Electrical Equipment

- 92/31/EEC Electromagnetic Compatibility

- HEI Heat Exchanger Institute

- HEI 120 Standards and Typical Specifications for Tray Type Deaerator