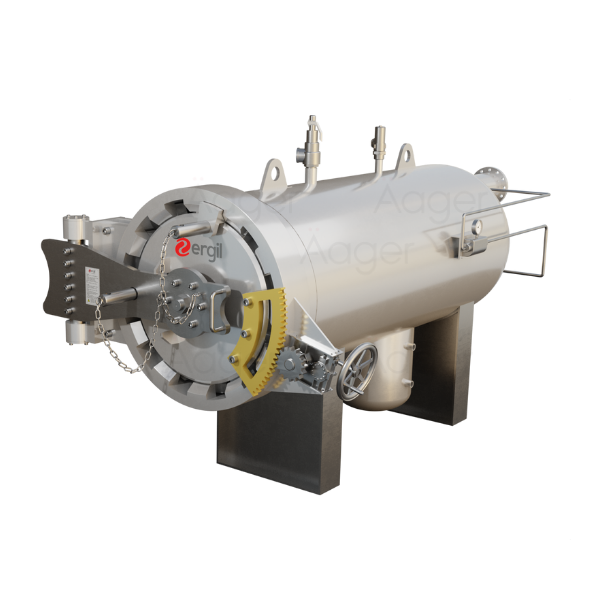

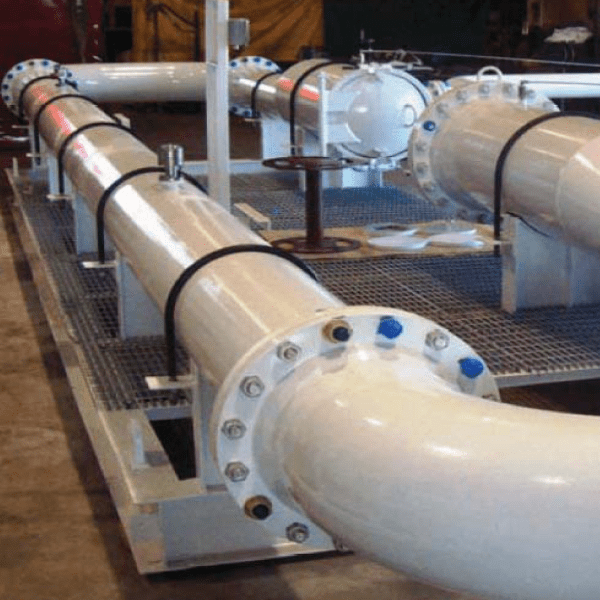

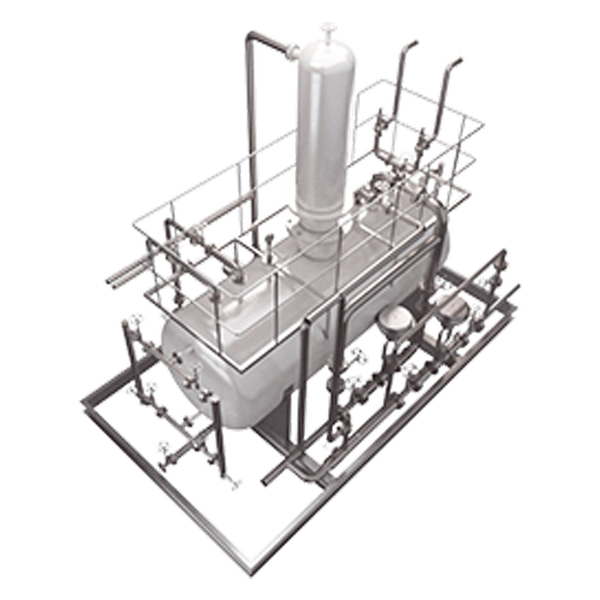

Crude Unit Preflash Drums and Columns

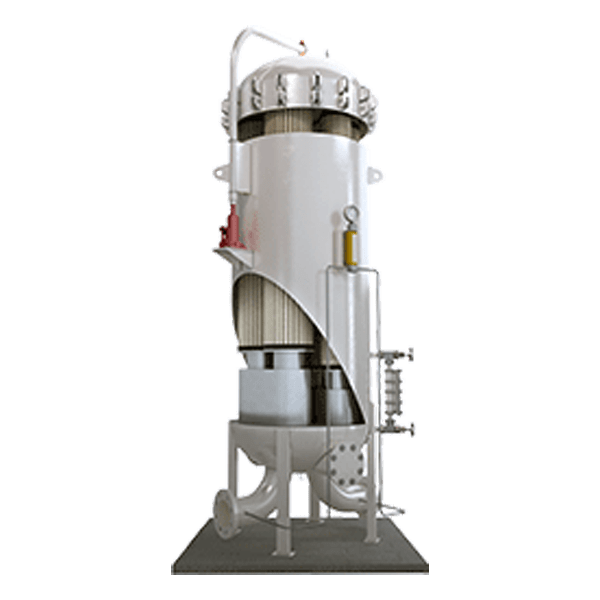

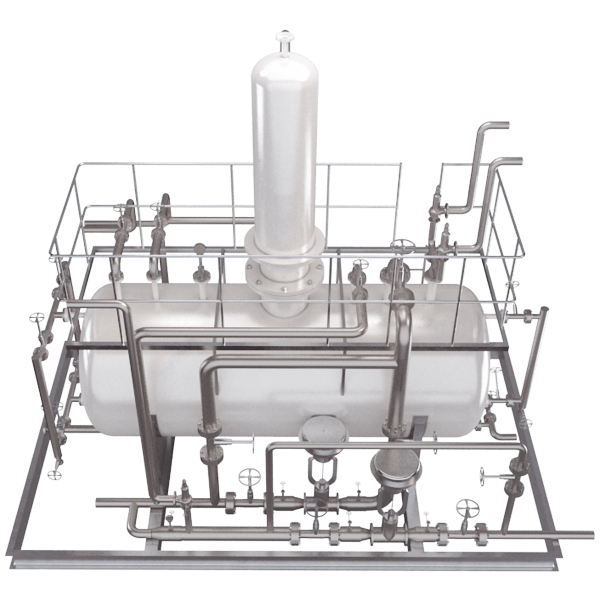

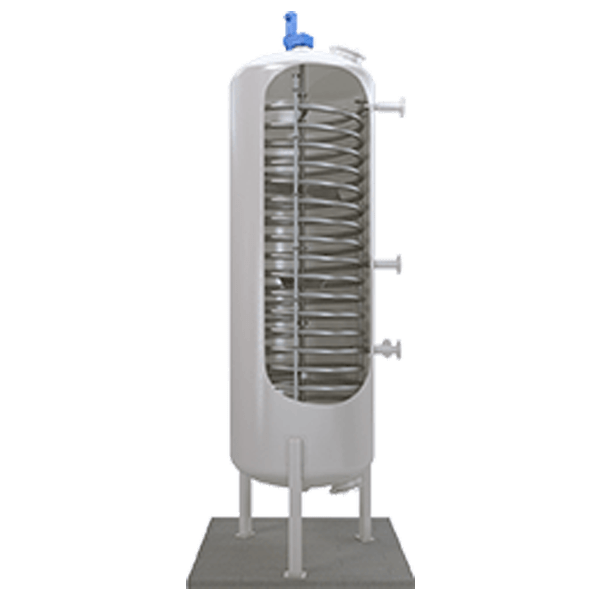

ERGIL design and fabricate with ASME U Stamp certification crude oil preflash drums, columns, and towers. These are used to manage crude hydraulics during grassroots crude unit designs and to increase crude capacity when revamping. The installed cost difference between the drum and column alone is relatively small. However, adding the cost of the columns’ peripheral equipment including the condensing system overhead drum and pumps raises investment costs considerably.

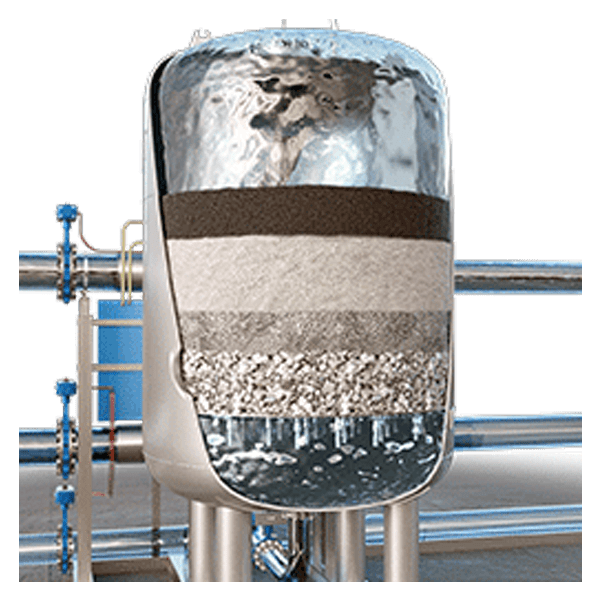

However, when existing atmospheric column condensers, drums, and overhead pumps are major limits to raising throughput or preventing the processing of lighter crude oils, installing a column and condensing system can be more cost-effective than modifying an existing atmospheric column overhead system. This work can be completed before the turnaround to reduce downtime. Drums or columns are a portion of the crude and water between the desalter and crude charge heater. The amount of hydrocarbon vapourised depends on the temperature and pressure in the drum or column. A two-phase feed is created when the operating pressure is reduced upstream of the drum or column. ERGIL’s expertise includes but is not limited to stripping columns, distillation columns (vacuum columns), fractionating / fraction columns, and debutanizer columns.