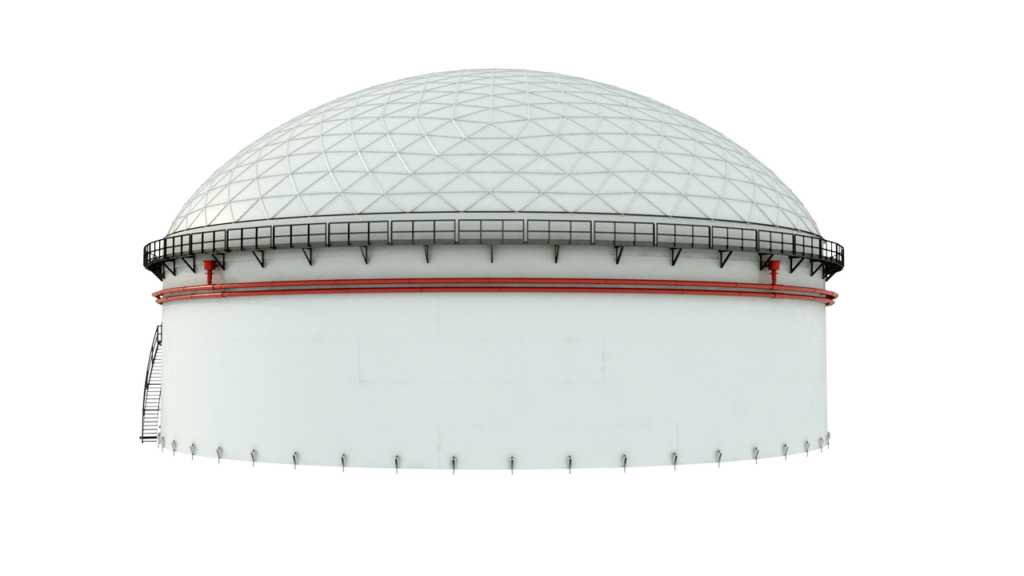

Factors Affecting Aluminum Dome Roof Performance

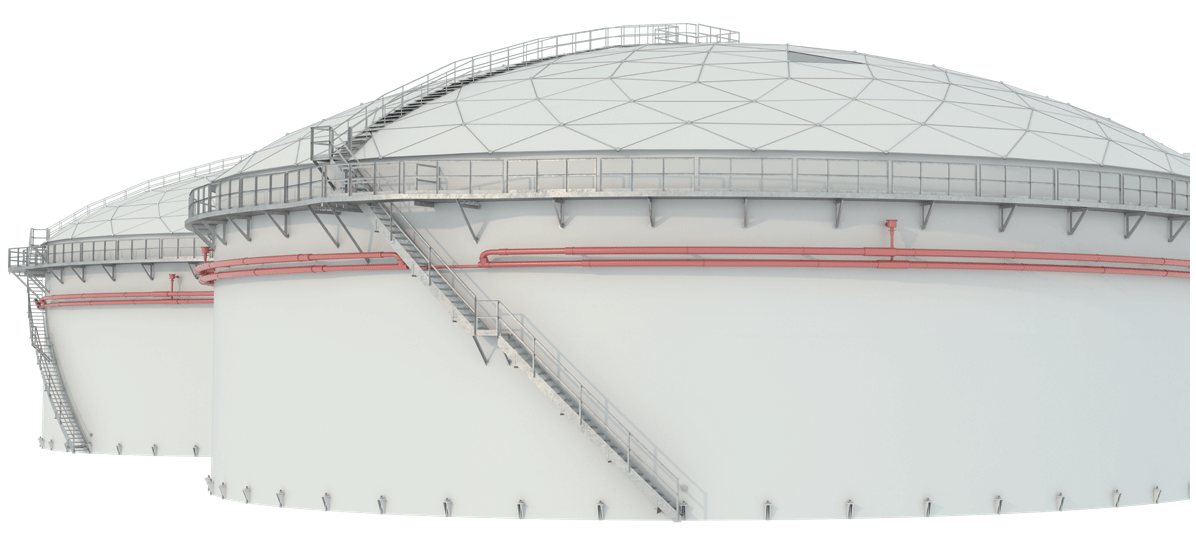

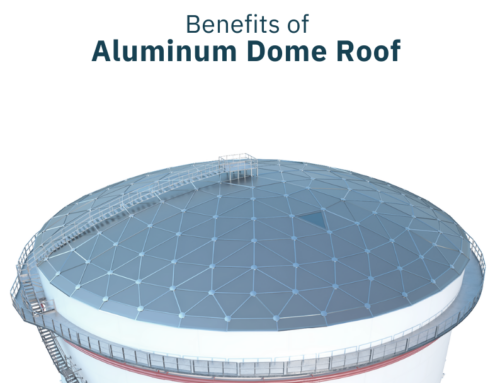

Storage tank construction is full of challenges and requires strict experience and high health and safety measures. Even perfectly built storage tanks face catastrophic accidents because of wrong design and low material and labor quality. Even Though, bottom and shell of the storage tank comes with its own challanges, no component carries more potential for property damage or personal injury than the roof. As aluminum geodesic dome roofs have become more and more popular, we see more and more performance failures. Unfortunately, storage tank aluminum dome roof design requires niche experience in multiple disciplines; such as aluminum structural design, civil and mechanical design with high chemical product knowledge, therefore it is very difficult for a non-expert to do the technical evaluation and design approvals. Consequently, the industry depends on manufacturers like us. Here we are listing out main factors that are affecting aluminum dome roof performance and collapse.

Inherent design errors that does not comply with API 650-G

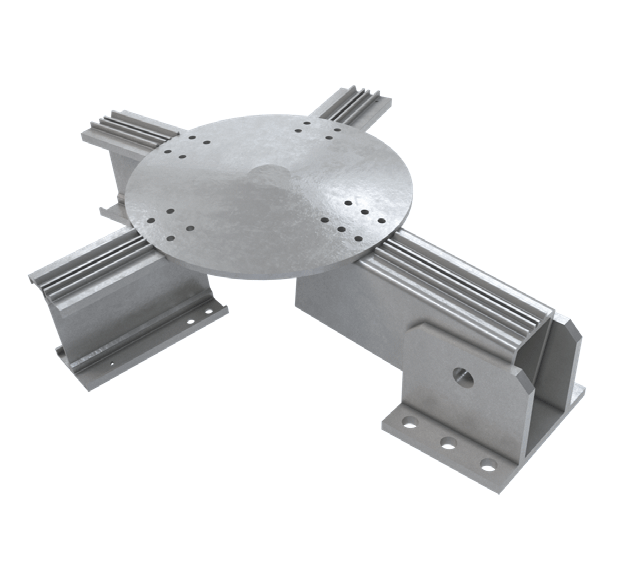

Designing a self supported aluminum dome roof for highly critical applications; such as hydrocarbons, chemicals or waste water is very challenging. Since misleading and outdated design calculations are very difficult to analyze, identifying mistakes, it is very difficult for non-experts to point out non confirmed points. Manufacturers who use conservative manual or Excel calculations are not able to cope up with industry demands, and foresee mistakes. Thanks to technological developments, it is now much easier to design a dome roof with the right tools. A successful design requires a minimum of ; structural analysis software, 3D CAD design software, and structural design of steel connections. Aluminum structural members shall be designed in accordance with the API 650 G3.1 aluminum design manual. G.4.1 Design Principles

Local design parameters: Rain, snow, winds, load …etc

Dome roof is self supported and light weight structure, therefore seismic, and panel load parameters have to be considered as per local zone conditions and designed accordingly. For the sake of competitiveness, we see a lot of manufacturers are using the same parameter in their calculation methods. Remember dome roof cost increases as load increases, so does the price. In order to protect the structural integrity, you can follow API 650 Appendix G.4.2 guidance for general understanding.

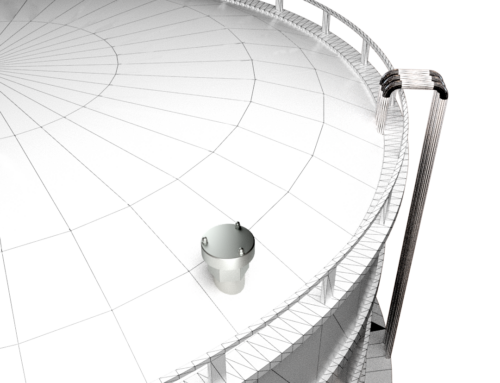

Water tightness

Water penetration can damage the products inside the tank and damage the internal floating roof or make them sink completely. In order to avoid this, you have to make sure you use the right seal material and type, control the bolt torque, and water test the roof before and after the final installation. Deterioration and water intrusion has to be identified in early stages and fixed before it escalates.

Light structures ( lighter profiles ) in order to reduce cost

Light structures ( lighter profiles ) in order to reduce cost

Dome roof consists of a highly available commodity; aluminum, however it is an engineered product, which requires highly skilled engineering skills and modern design softwares. In order to compete, manufacturers take risks and use lighter profiles that do not comply with design requirements. Moreover, they use the “lightweight” term as if it is an advantage, however most of the cases, they are not complying with API 650.

Not considering safety factors

Using the right safety factor is crucial for dome roof design. Designs with less risk factors, provide lighter profiles, less connection points and are not taking long-term enviromental effects into account.

Not considering Internal pressure

The internal design pressure shall not exceed the weight of the roof, however manufacturers either do not have enough technical knowledge or avoid this in order to reduce the cost. It is also very common to use the same old design for multiple applications, therefore they do not change the parameters for individual parameters thinking that minor issues will not cause big changes.

Using cheaper bolts in order to reduce cost

Manufacturers intend to use threaded bolts instead of lock bolts, which are more expensive but much more reliable. In addition to that, the quantity of the bolts has to be calculated according to the best industry standards. As stated in API G.2.4, “Bolts and Fasteners: Fasteners shall be of 7075-T73 aluminum, 2024-T4 aluminum, austenitic stainless steel, or other materials as agreed to by the Purchaser. Only stainless steel fasteners shall be used to attach aluminum to steel”.

Seal type: wiping or compressed ?

Generally manufactures use two types of seals; wiping or compresses for batten bars that are connected to panels. Better option is a compressed seal, however it is more costly. Wiping seals in nature are not as rigid as compress seals and deform by the time. Those seals are usually made of Neoprene, EPDM, NBR, or Silicone. As “stated in API 650 G.2.5.2 “Preformed gasket material shall be Neoprene, silicone, Buna-N, urea urethane, or EPDM elastomer meeting ASTM C509 or Federal Spec ZZ-R-765C unless another material is required for compatibility with stored materials” and “Sealants shall be silicone or urea urethane compounds that conform to Federal Spec TT-S-00230C unless another material is required for compatibility with stored materials. Sealants shall remain flexible over a temperature” in appendix G.2.5.1.

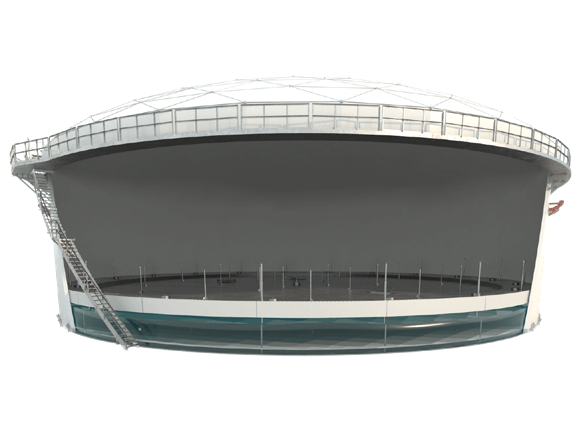

New Tank Vs Existing Tank Design

Whether it is a new tank or an existing tank, you can install a dome roof, however converting an existing traditional tank roof ( cone, flat or external floating roof) requires custom design solutions. Main tank design has to be taken into consideration and go over the existing design just to make sure if shell thichness, and bottom connection are suitable for carrying a dome. Especially converting an external floating roof can be challenging, and it may end up with devastating and long-term consequences.

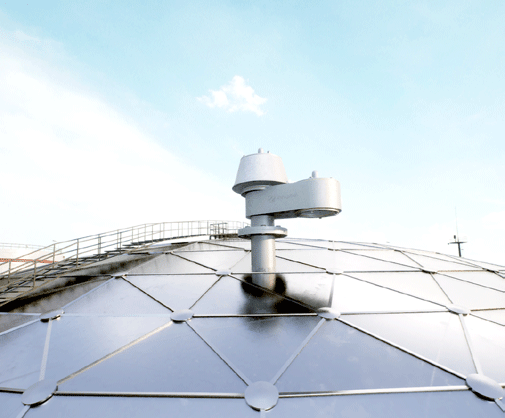

Erection

We see that even with the high quality dome roofs face problems because of erection. In theory, dome roof installation is easy and safer compared to traditional roofs, however it is always recommended to have an experienced supervisor on site to help correct assembly and installation. Supervisor is very helpful to guide the team to apply correct torque, make sure sealing is applied correctly, and assist with the correct testing method.

Superior Engineering: We use the latest engineering structural analysis software, 3D CAD design software, and structural design of steel connections as compared to traditional outdated calculation methods.

Designing with local parameters in mind: We design our dome roofs as per local environmental, and seismic parameters with keeping regulations in mind.