Project Oveview and Challange

Gazprom Neft Middle East, a subsidiary of Gazprom Neft, has assumed the operatorship of the Sarqala field (Garmian block), located in the Kurdistan Region of Iraq (KRI). Operatorship was transferred pursuant to the production sharing contract for this field, signed in 2012. Western Zagros Resources Ltd was previously operator on the project. Work on the field is now being managed by staff of Gazprom Neft Middle East.

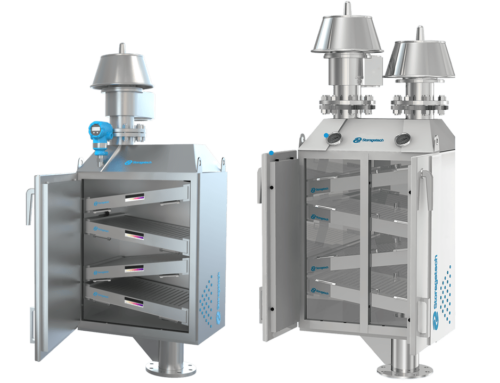

First oil at the Garmian block was achieved in 2011, with commercial production commencing in 2015. As at 1 March 2016 total production at the field had reached 2.7 million tons. ERGIL provides appropriate solutions for refineries. Degassing boot is a two phase separator (liquid/gas) with internals to induce the free gas separation to different operating conditions in liquid feed.

Action

Action

ERGIL has collaborated with Gazprom Neft Middle East B.V. on a project that includes the designing, fabrication and supplying of gas boot and knockout drum with unique internal separator element design that provides optimum

performance. Here are some technical specifications for the products we supplied:

For knock out drum:

• 2.4 diameter, thickness 22 mm and 18 meter length,

• Pressure 3.5 bar full vacuum,

• Design temperature between -10 / + 110 degree,

• RT, UT, PT tests,

• Mechanical calculation and process calculation is done,

• Calculated performance 99%,

• ASME U Stamp certified,

• Design code ASME Section V III Division 1.

For gas boot:

• Design pressure 3.5 bars, full vacuum,

• Design temperature between -10 / + 125 degree,

• RT, UT, PT tests,

• Mechanical calculation and process calculation is done,

• Design Code ASME Section VIII Div. 1,

• ASME U stamp certified, inner diameter 1.5 meters, height 20 meters.

Also for both of items platforms and stairs are supplied. Gas boot is designed to separate production fluids into their constituent components of oil, gas, and water. Separator designates a pressure vessel for separating well fluids produced from oil and gas wells into gaseous and liquid components. They are normally used on a producing lease or platform near the wellhead, manifold, or tank battery to separate fluids produced from oil and gas wells into oil and gas or liquid and gas. Knock-out drum, either Horizontal or Vertical type, is designed to remove liquid entrainment in gas & accumulate condensed & entrained liquids from the relief gases. Knock-out drum is important to make sure that when gas reaches to flaring section, it contains no liquids, water or any type of fuel. If a mixture of gas and liquids reached the flaring section, this would cause with very dangerous consequences.

Result

ERGIL completed factory acceptance test for the oil, gas, water separator gas booth, and knock-out drum and deliver them successfully to Gazprom Sarqala Project in Northern Iraq. ERGIL, with a dedicated and experienced staff, offering high-quality oil, gas, water process equipment manufactured with professionalism, continues to extend its references in separation segment. ERGIL offers a wide range of custom made high and low-pressure vessels for the

processing, storage, and transport of bulk liquids and gases; such as deaerators, absorbers, surge vessels, filters

and coalescers, process towers and columns along with shell and tube type heat exchangers.

Please Click for the PDF Format: Case Study of Gazprom Sarqala Project Iraq