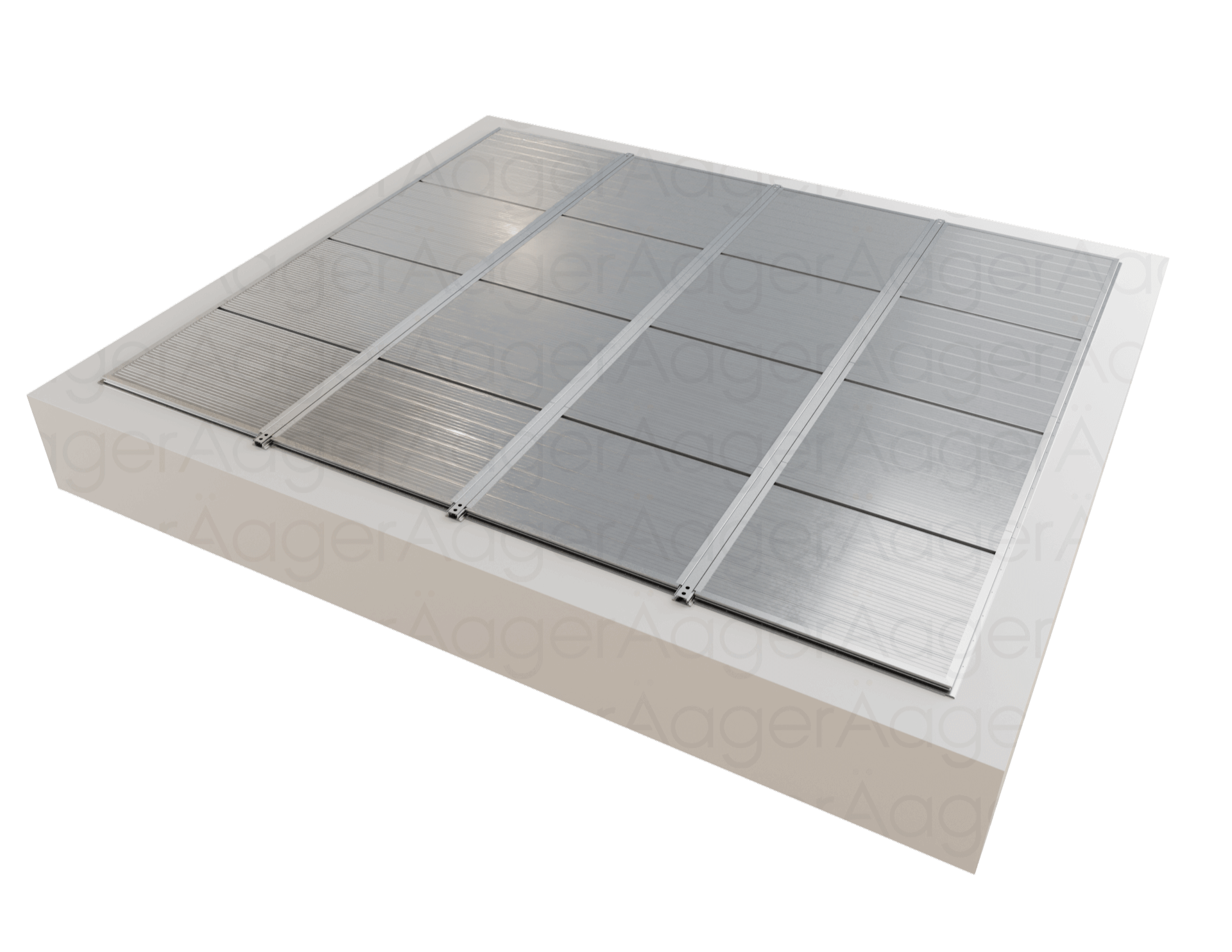

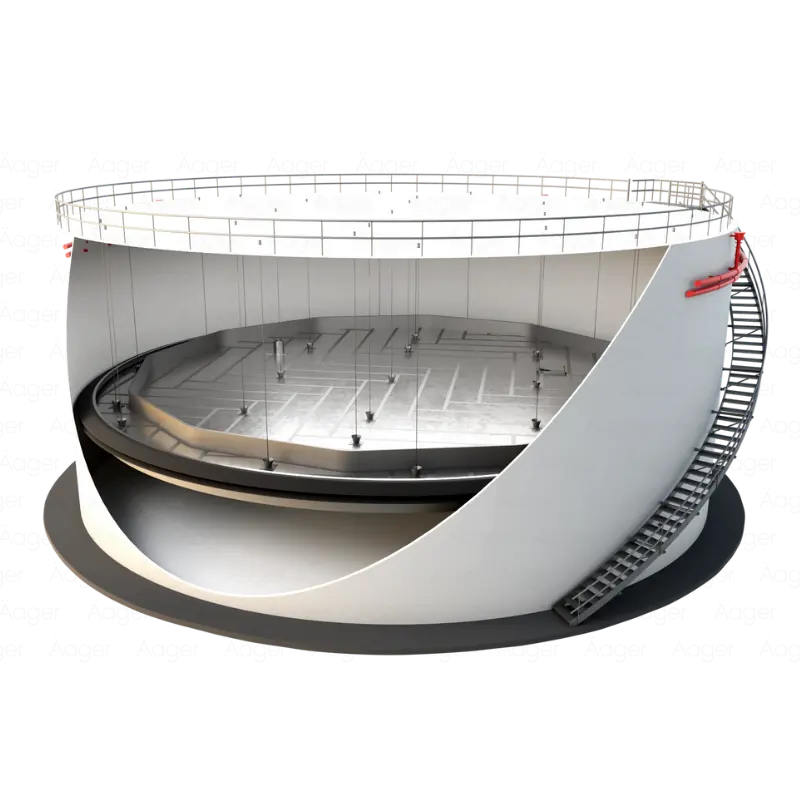

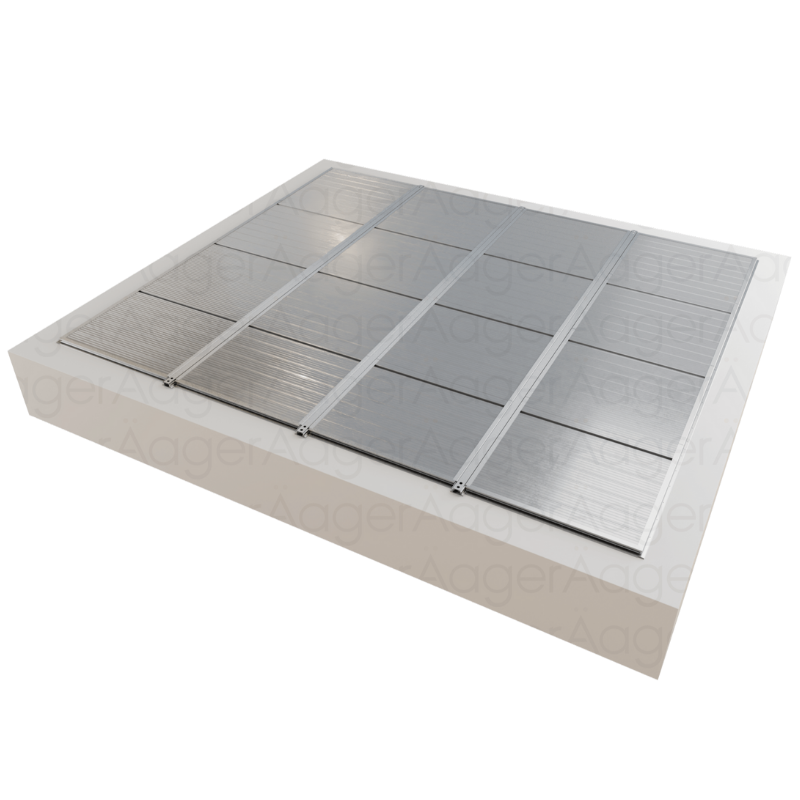

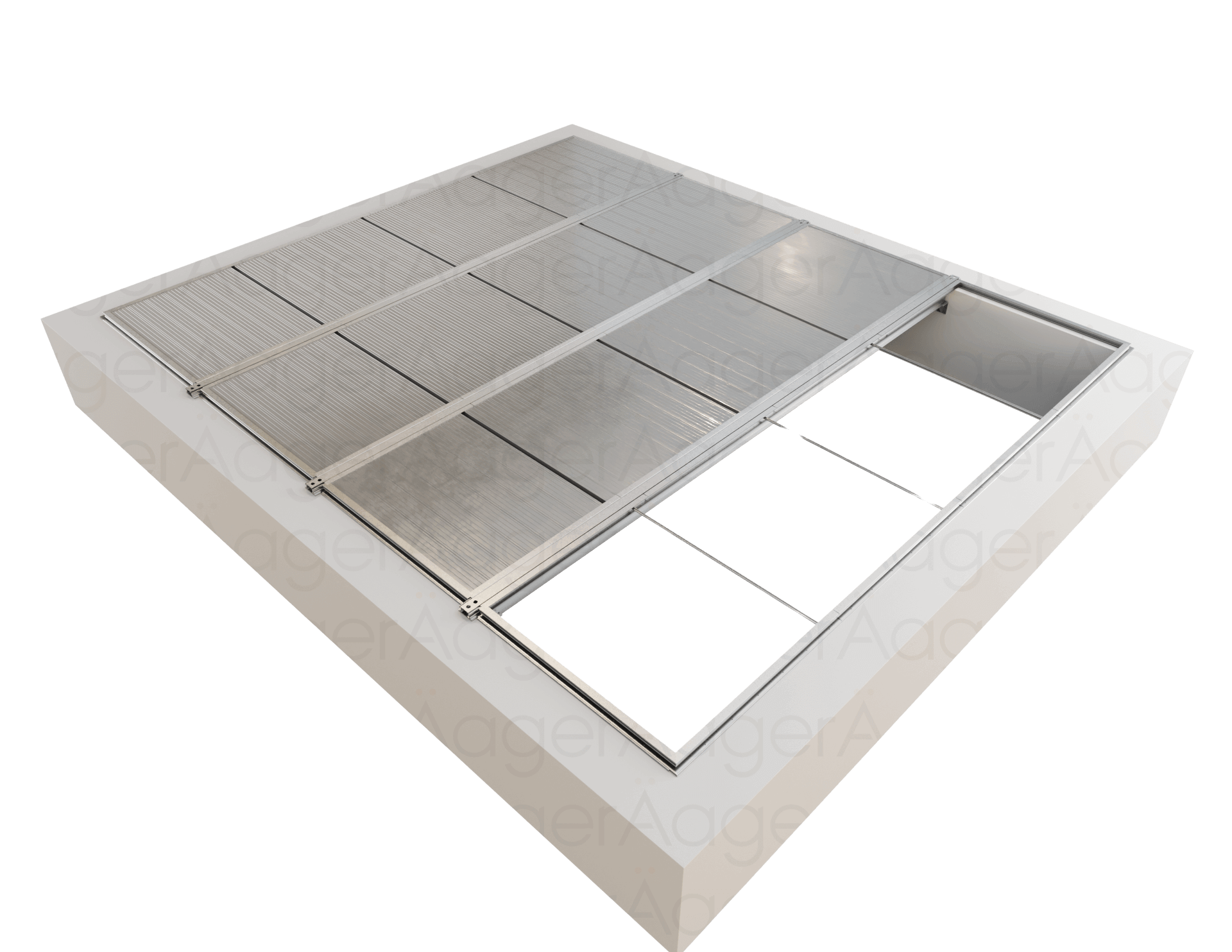

Aluminum Flat Cover

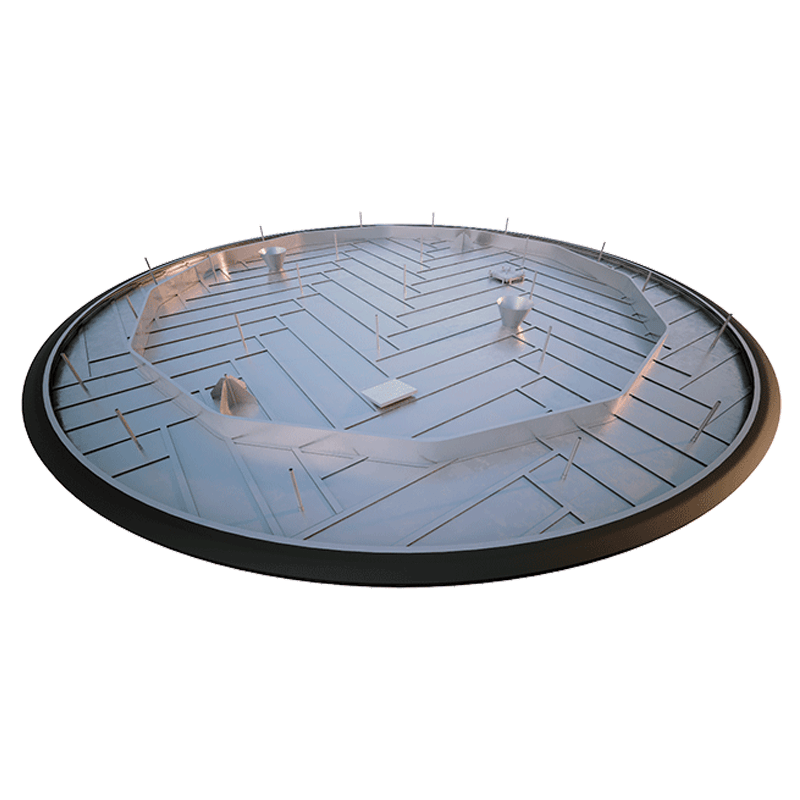

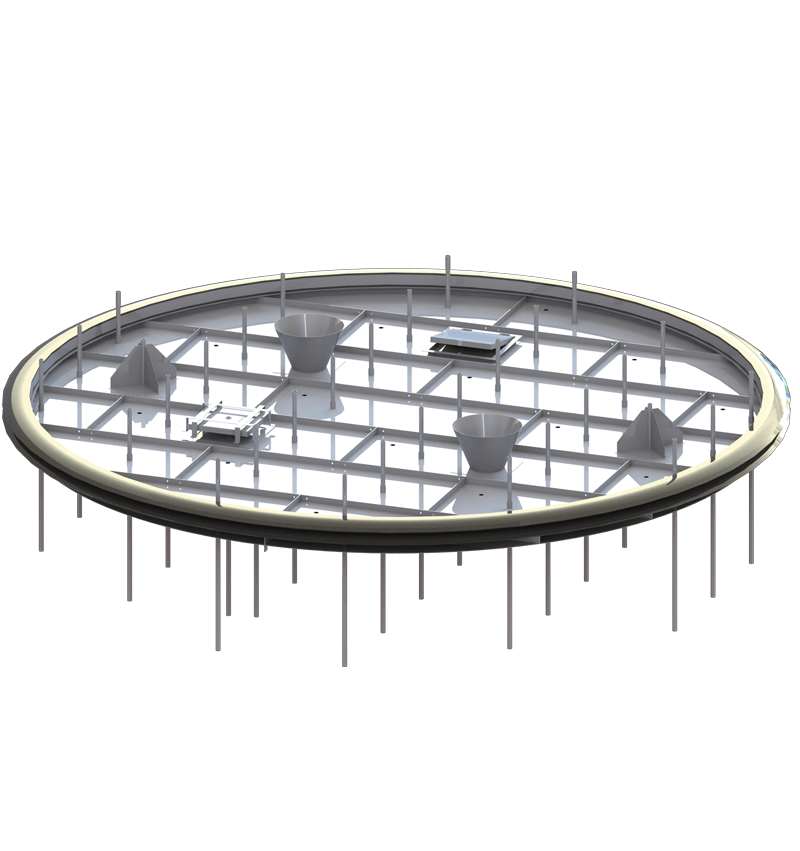

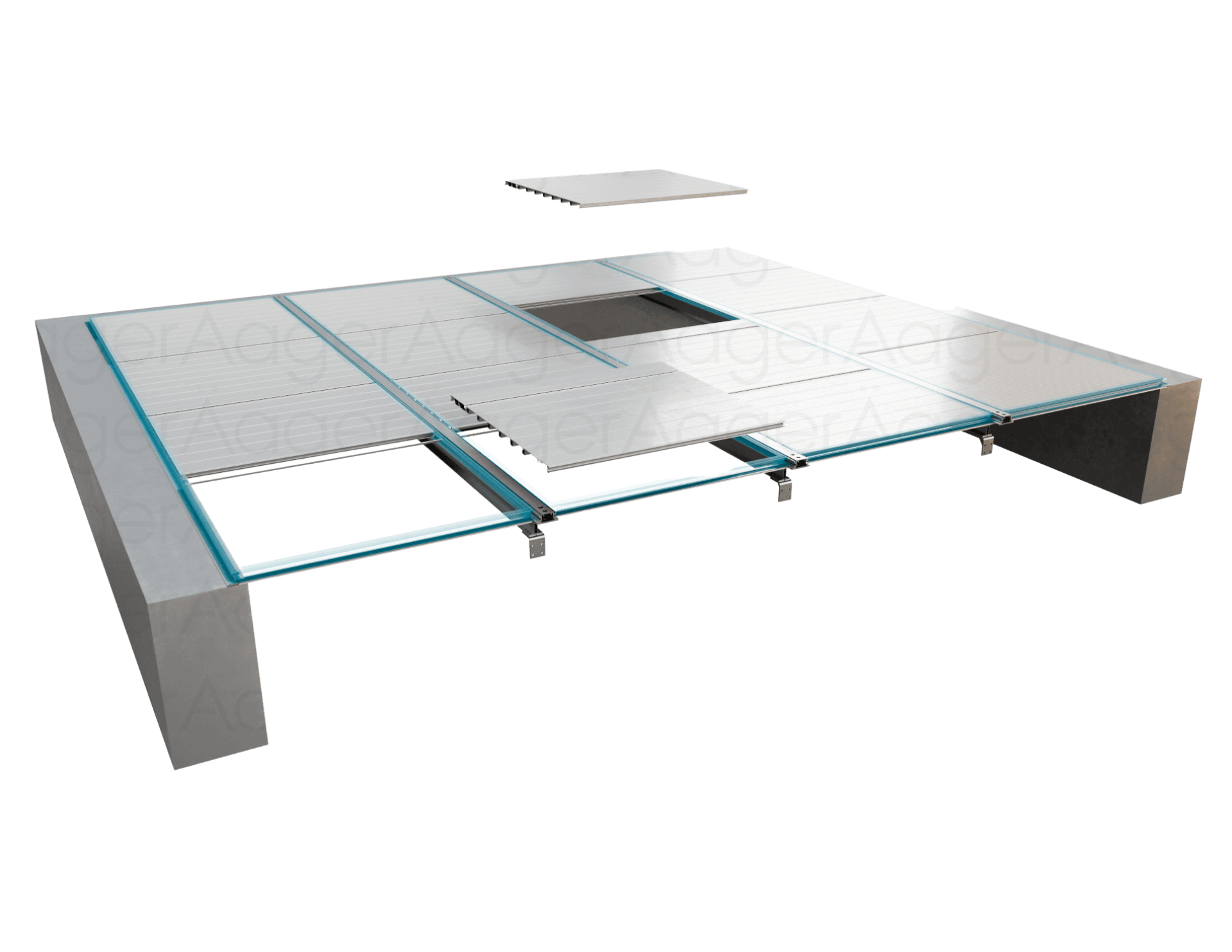

Storagetech’s Aluminum Flat Covers offer a robust and cost-effective solution for covering water and wastewater treatment units. Designed for gas containment and odor control, these covers are ideal for clarifiers, sludge holding tanks, and biological treatment tanks.

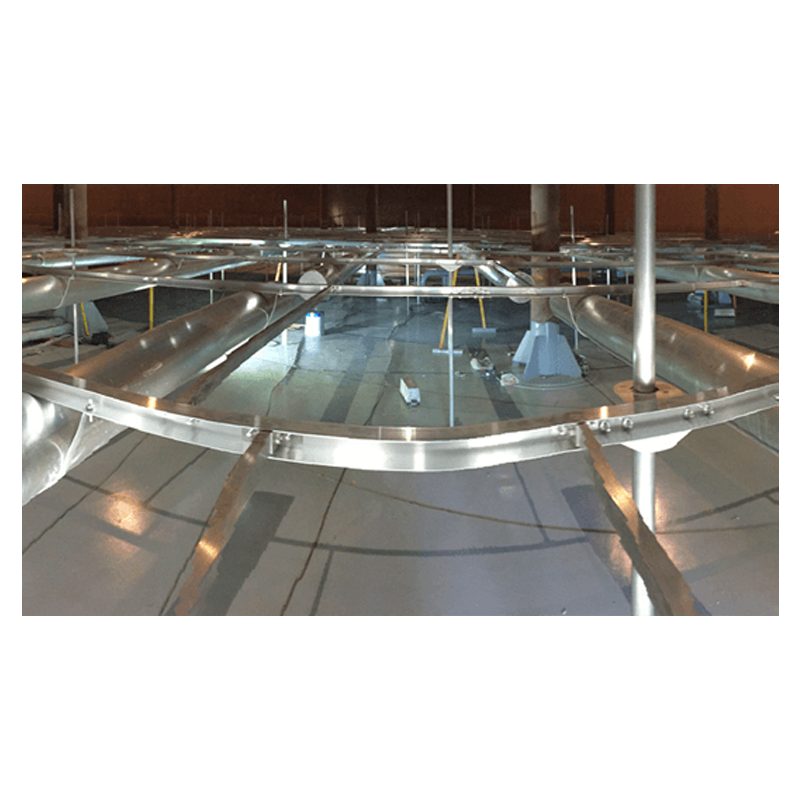

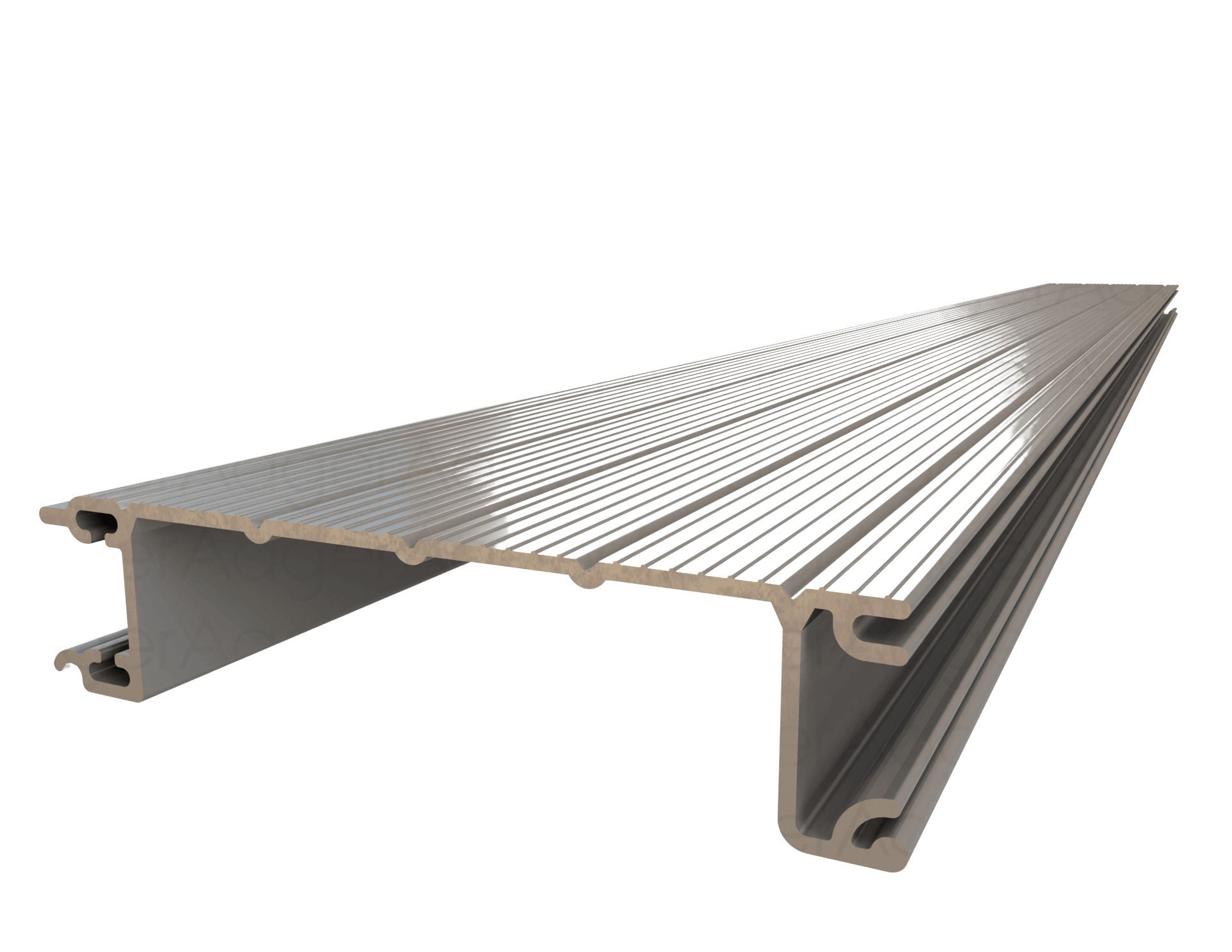

Manufactured from high-grade 6061-T6 and 6063-T6 aluminum alloys, the structure ensures exceptional resistance against chemical corrosion, UV exposure, and harsh weather conditions. Their modular configuration allows for quick installation, simple maintenance, and scalability across various project sizes.

Applications

• Municipal and industrial clarifiers

• Sludge and digester tanks

• Biological and aeration basins

• Chemical storage and recovery vessels

• Odor control facilities

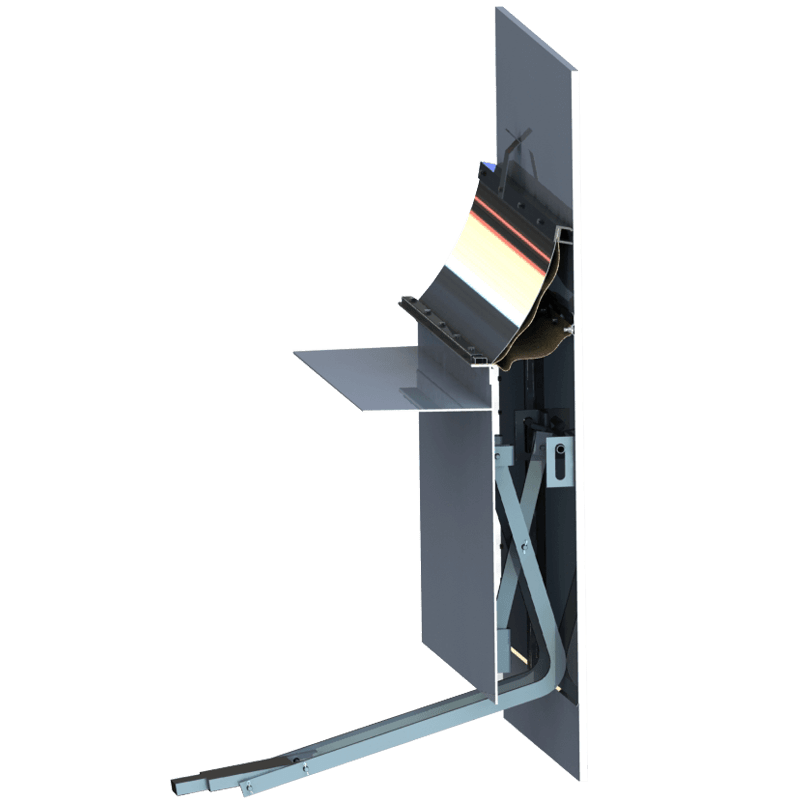

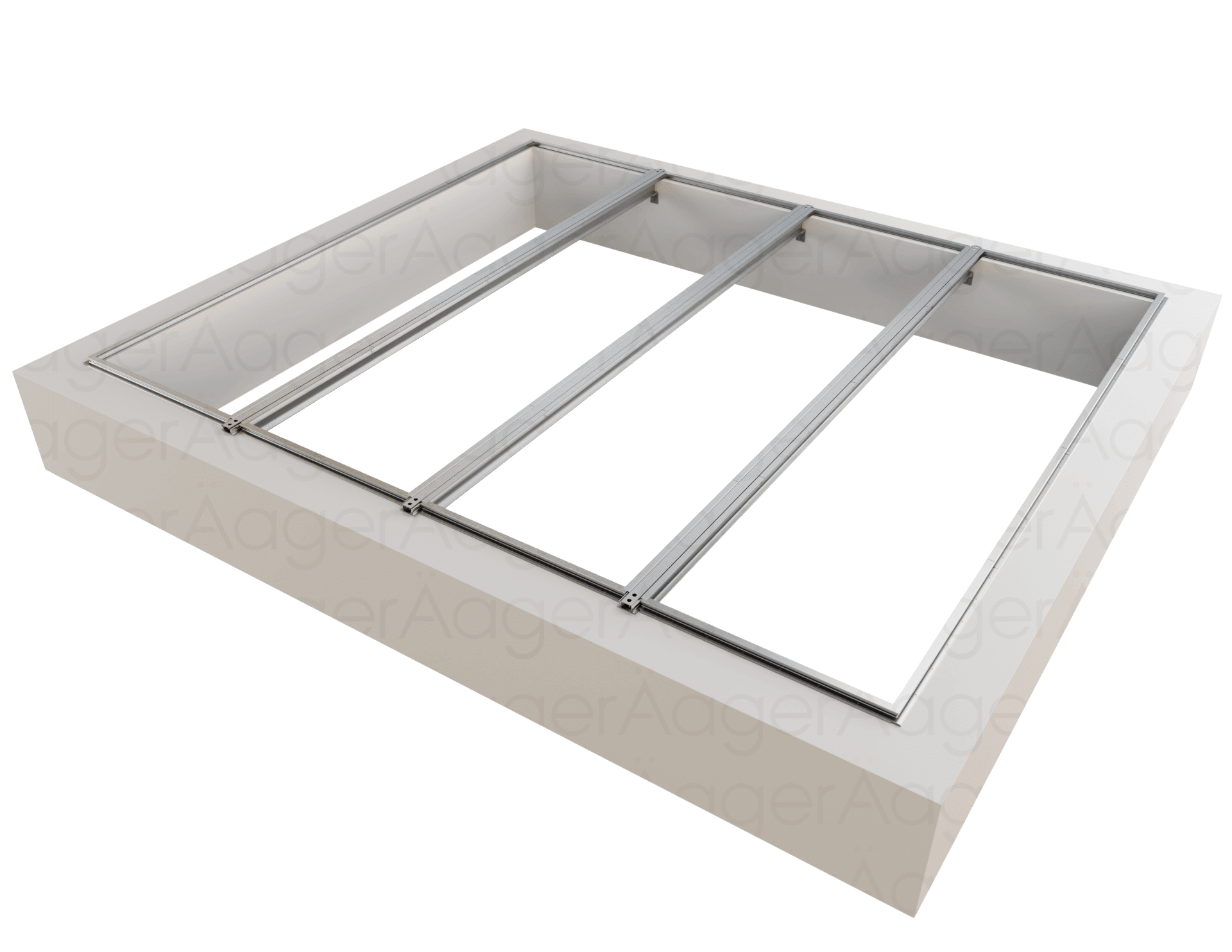

- Modular lightweight panels for fast and easy installation.

- Corrosion-resistant materials for harsh chemical environments.

- UV-protected surface coating for long-term durability.

- Neoprene gaskets ensuring tight sealing and odor control.

- Low-profile design minimizes secondary containment requirements.

- Reduces energy load when integrated with odor scrubbers.

- Minimal maintenance required—no special tools needed.

- Material: 6061-T6 & 6063-T6 Aluminum Alloy

- Load Capacity: 181 kg (400 lbs) on 152×152 mm area

- Deflection: Max 1/240 of span length

- Gasket: UV and H₂S-resistant neoprene

- Standards: API 650, AWWA D108/D100, ASCE 7, ADM 2020, Eurocode

- Leak Test: ≤ 0.20 CFM/sqft

- Waterproof Test: 350 kPa pressurized water jet

- Analysis: ANSYS FEA per ASME VIII Div.2

- ASME Section VIII Div.1 & Div.2

- ASTM C509 for neoprene materials

- API 650 / API 2000 for tank integration

- AWWA D108 / D100 / D103 for water systems

- EUROCODE and IS 875 structural codes

Extended Feature Descriptions

Low Permeability

The design incorporates tightly sealed interlocking panels and neoprene gaskets to provide exceptional resistance to gas and vapor permeability. This ensures efficient odor containment and minimizes the release of harmful emissions, making it ideal for wastewater and industrial processing facilities.

Corrosive Chemicals Resistant

Manufactured using marine-grade 6061-T6 and 6063-T6 aluminum, the covers exhibit superior resistance to corrosive gases such as hydrogen sulfide (H₂S), methane, and VOCs. This makes them suitable for aggressive wastewater and sludge applications where chemical exposure is continuous.

Double Protection for UV Resistance

ERGIL’s covers are coated with a dual-layer UV protection system that guards the aluminum surface against prolonged sun exposure. This prevents material degradation, color fading, and structural weakening, extending the product lifespan even in the most intense environments.

Low Profile

With a compact vertical footprint, the cover’s low-profile design reduces headspace above tanks, minimizing the volume of contained gas. This efficiency improves performance of odor control systems and facilitates easy integration into tight architectural environments.

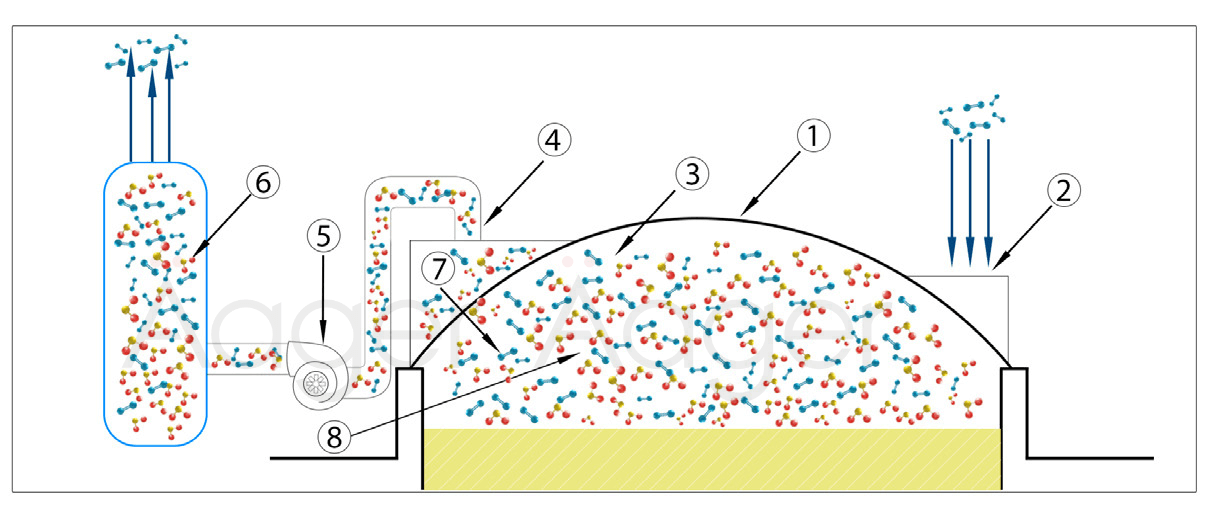

Comparison of Tank Roof Ventilation Systems

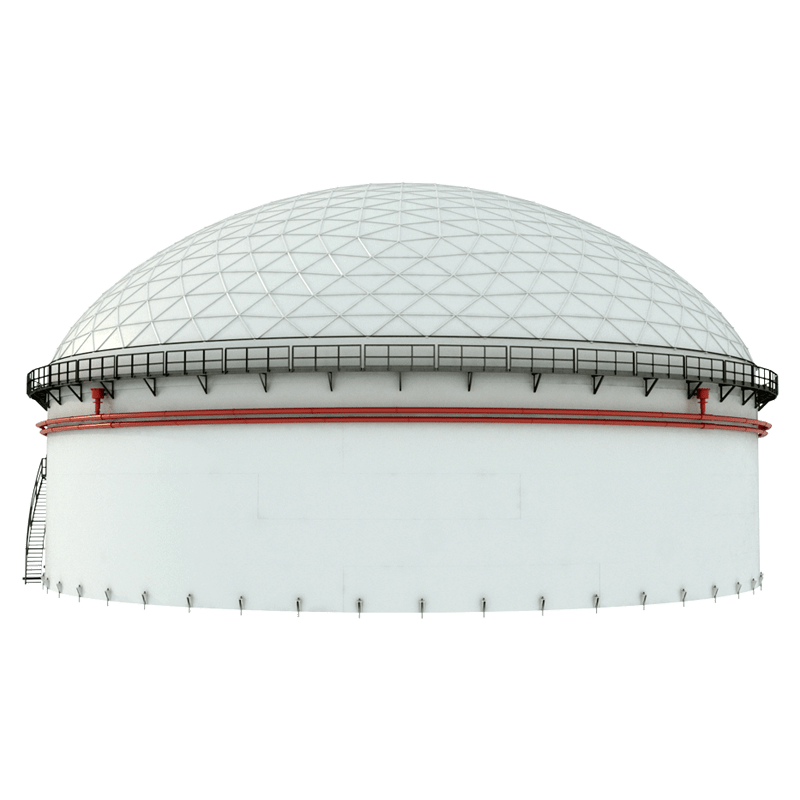

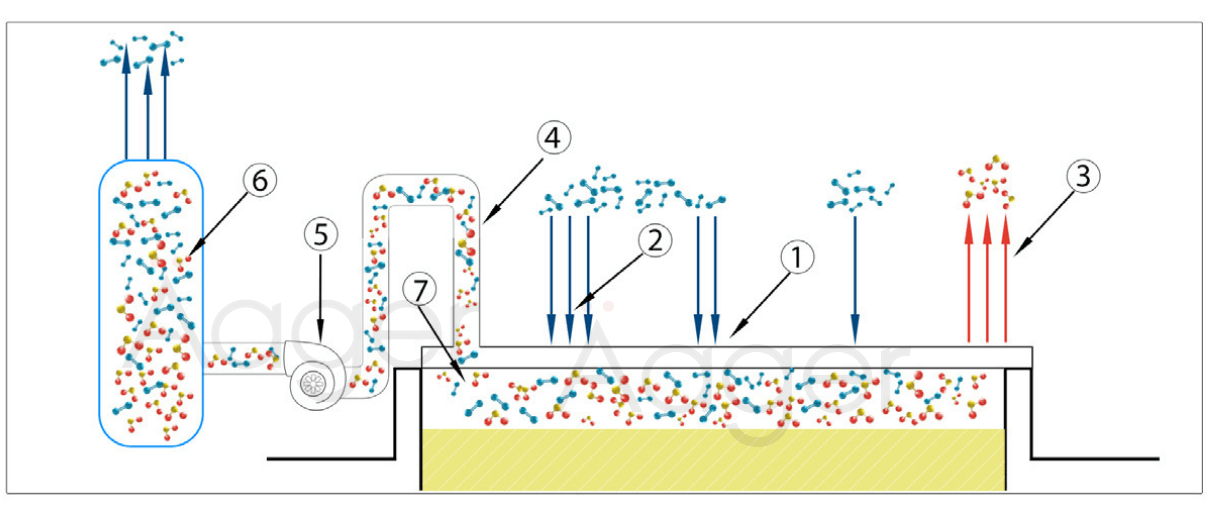

(a) Expanded Dome-Type Roof System

- Expanded dome-type roof structure

- Fresh air is forced into the system by fans through expanded entry points

- Confined area with unsafe VOC and HAP concentrations

- Larger diameter pipes

- Larger fan

- Larger purification units

- High usage of clean air

(a)

(b) Flat Roof System with Gaps

- Flat roof system with gaps

- Fresh air drawn into the system by fans enters through gaps between covers

- Uneven air exchange causing gas accumulation problems

- Large air duct dimensions required for processing higher air volume

- Large fans required for processing high air volume

- Large purification units required for high air volume

- Uneven air exchange with high concentration of fresh air

(b)

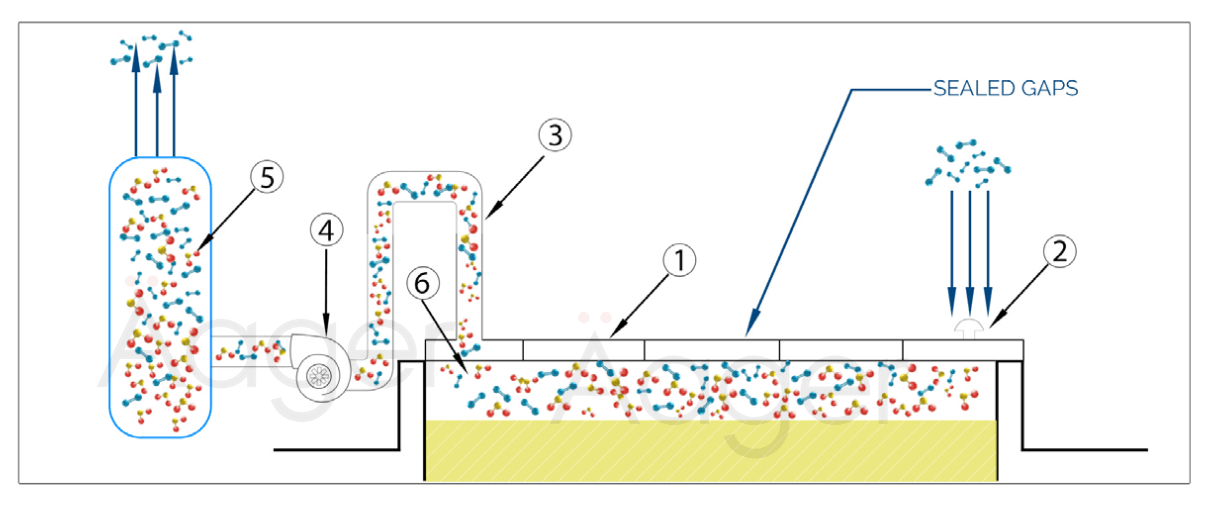

(c) Flat Roof System with Sealed Gaps

(e.g., Aluminum Covers)

- Flat roof system

- Controlled ventilation

- Smaller diameter pipes

- Larger outlet pipes

- Smaller fan

- Smaller purification units

- Controlled clean air use

- Minimal air exchange with minimal clean air usage

(c)

Energy Saving

By significantly limiting odor dispersion and heat loss, these covers reduce the workload of ventilation and treatment systems. This translates into lower energy consumption and operational cost savings over time—especially in large-scale treatment plants.

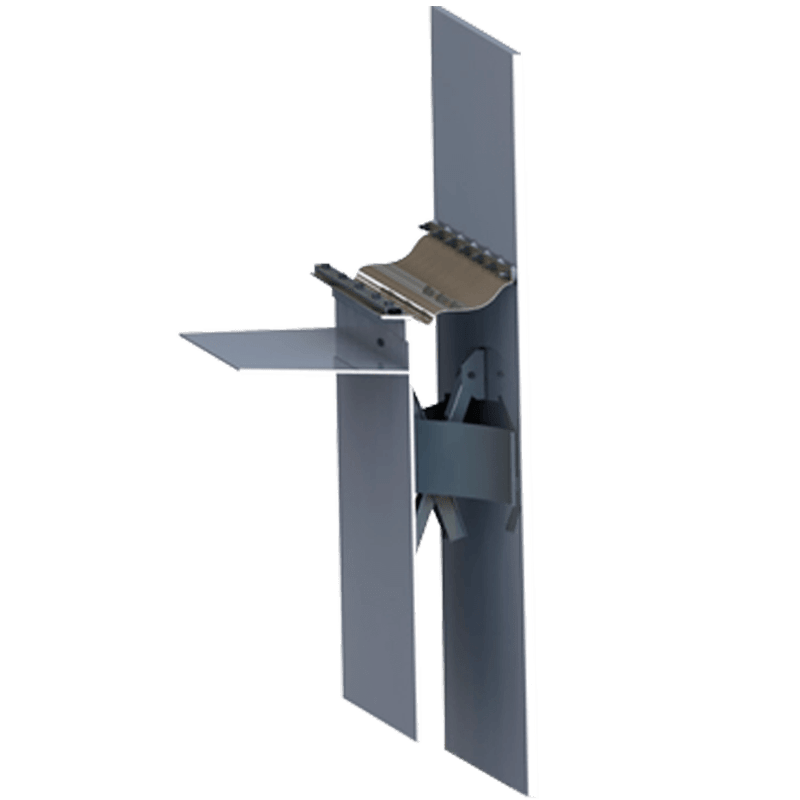

Maintenance Friendly

Thanks to a modular, tool-free assembly system, routine inspections and maintenance activities can be performed quickly and without specialized labor. All surface materials are easy to clean and designed for long-term performance with minimal upkeep.

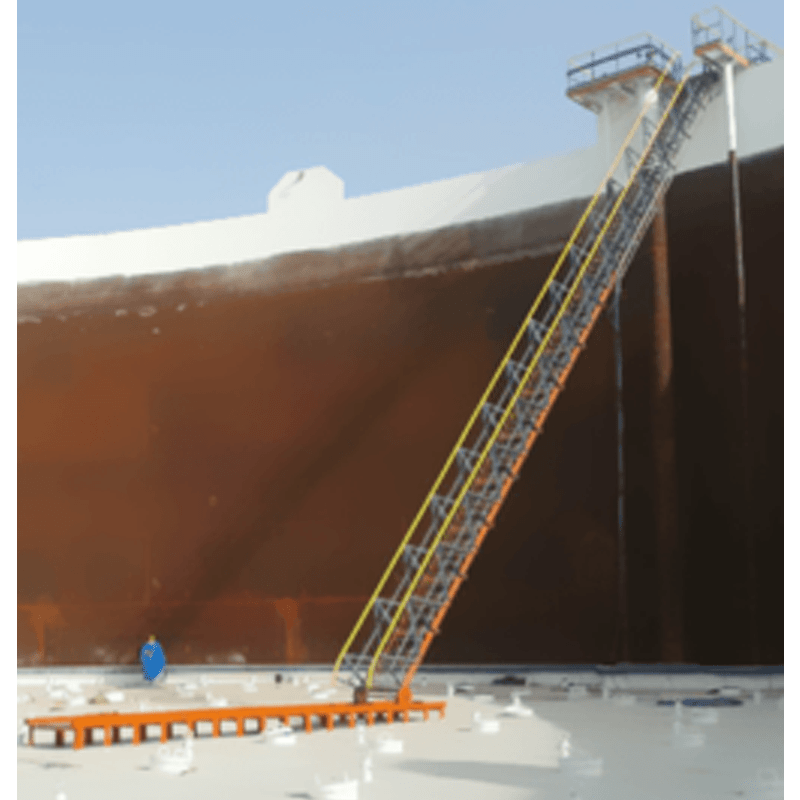

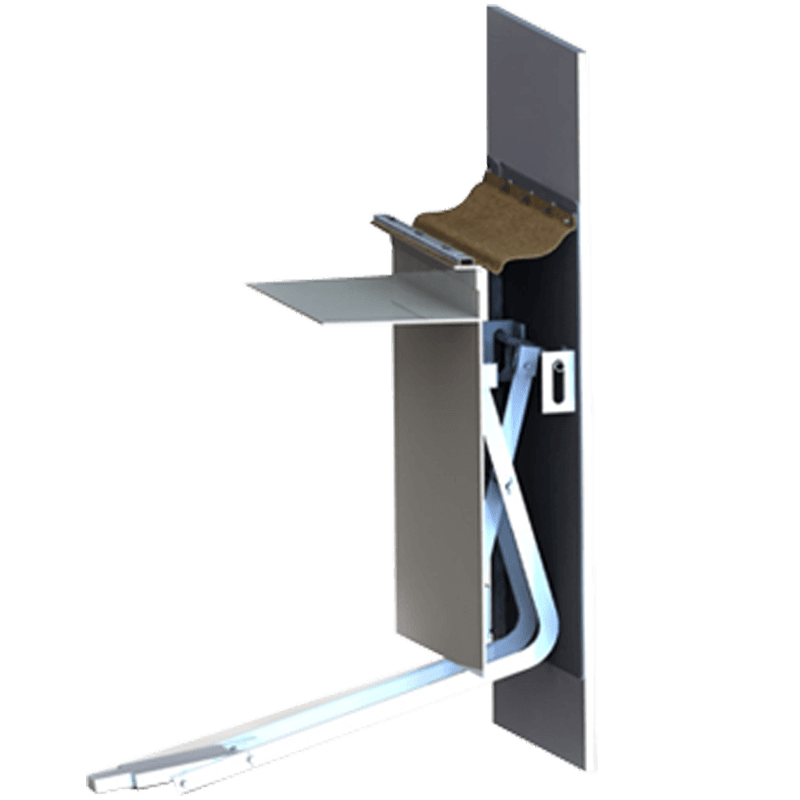

Easy to Install

Panels are pre-fabricated and lightweight, requiring only basic mechanical handling for positioning. Installation can be completed quickly on-site with minimal disruption to existing operations, making them ideal for retrofit and greenfield projects alike.