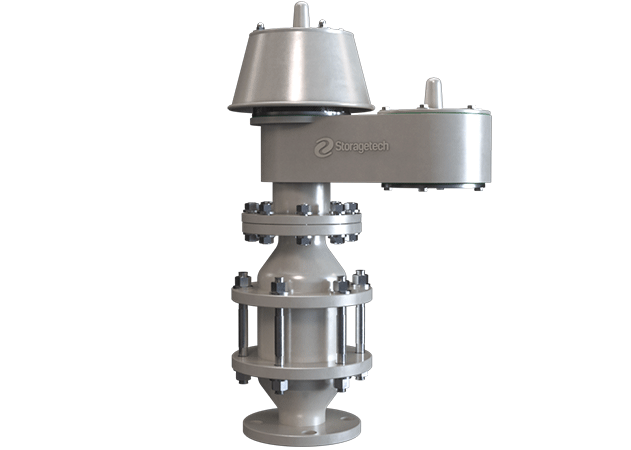

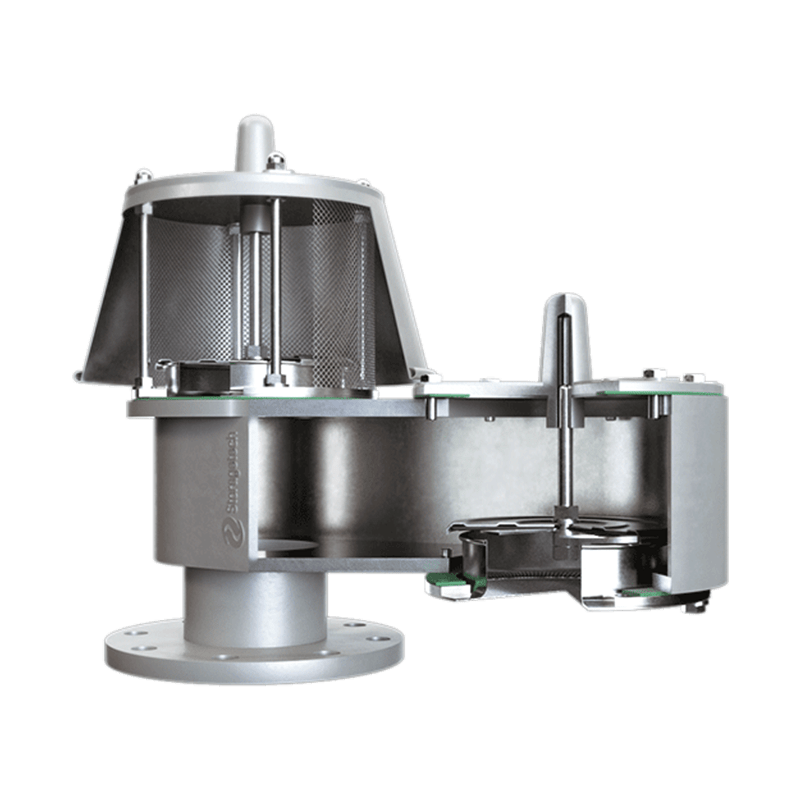

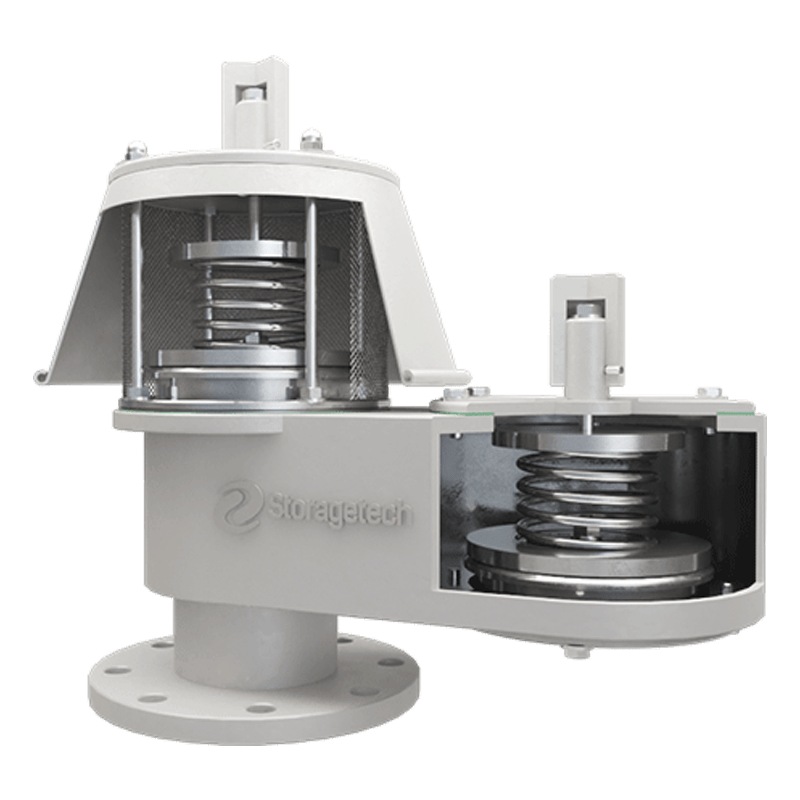

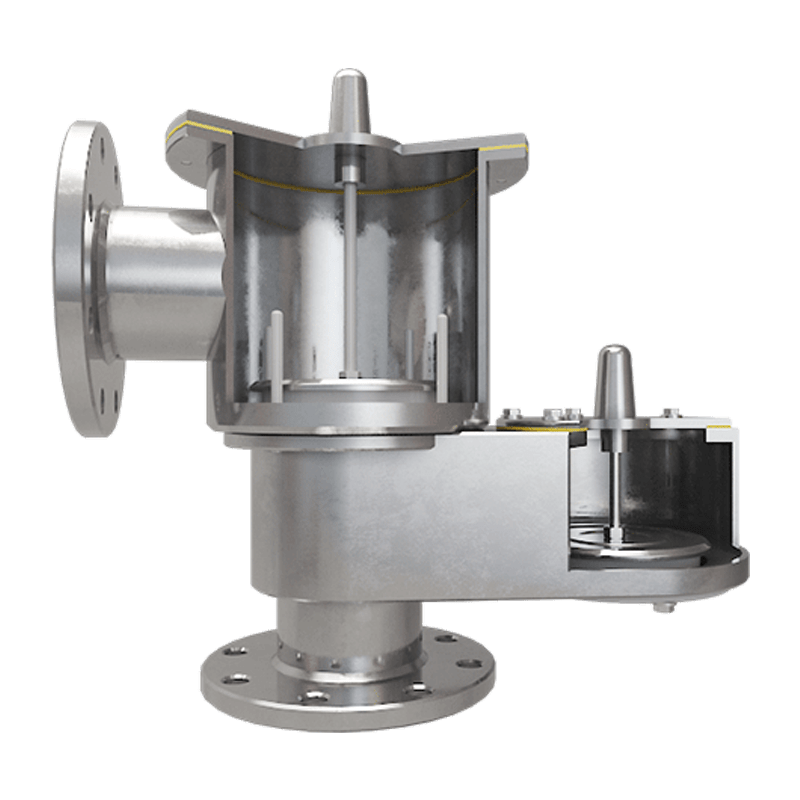

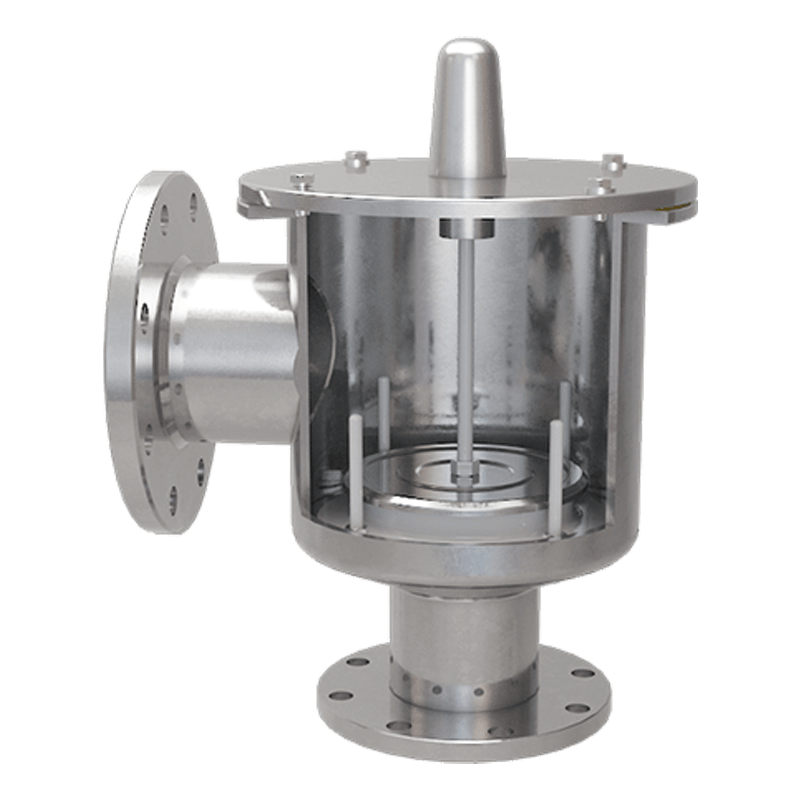

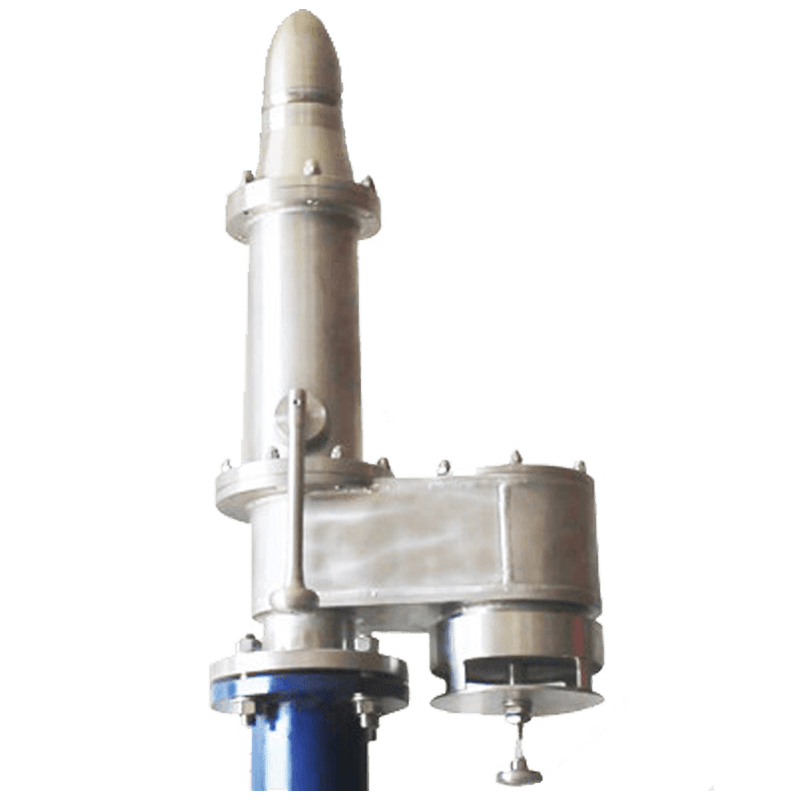

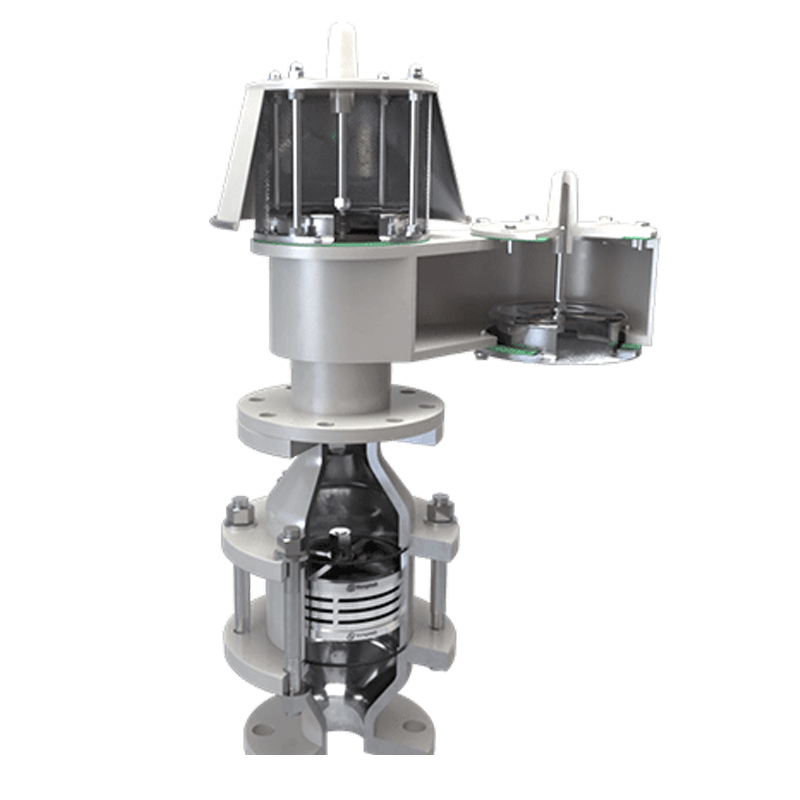

Pressure Vacuum Relief Valve with Flame Arrestor

Model No: 330

(End of line, weight loaded, combination, atmospheric deflagration proof)

The assembly of this pressure relief valve with an effective flame arrestor will enhance the safety of personnel, site location, and equipment, by reducing or eliminating the risk of flashover through the vent.

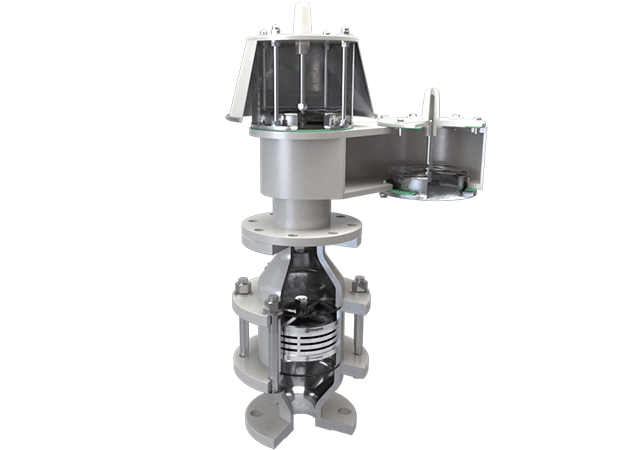

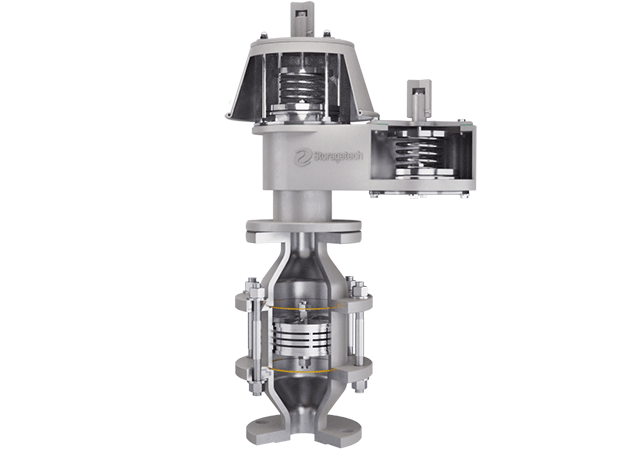

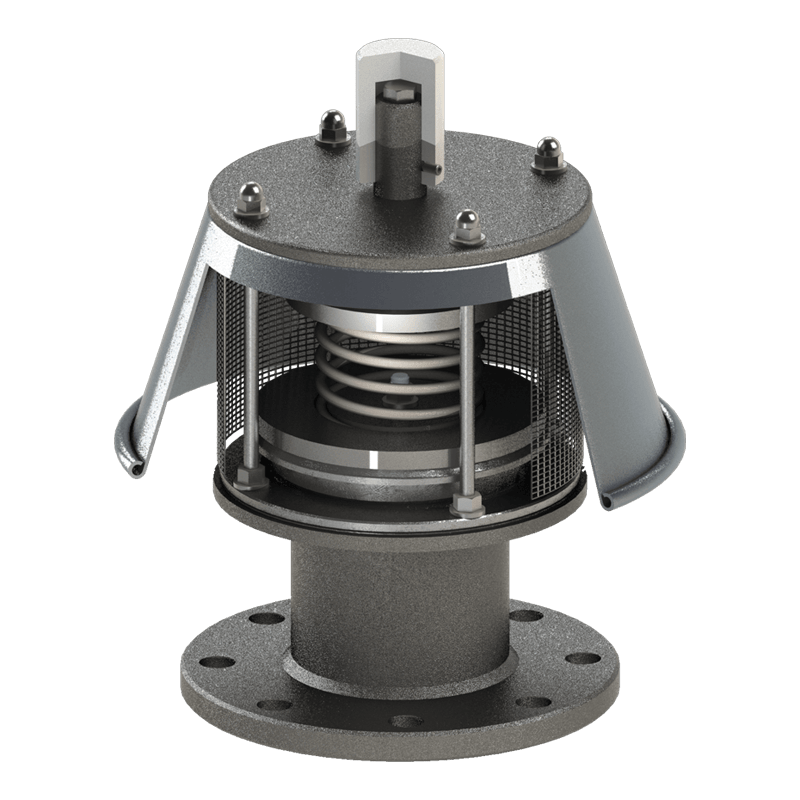

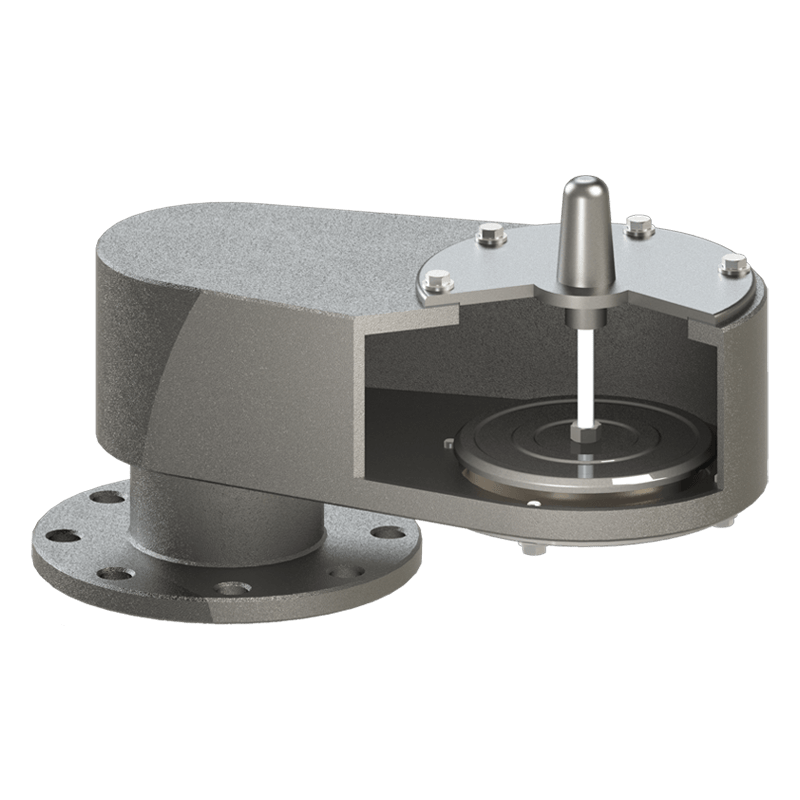

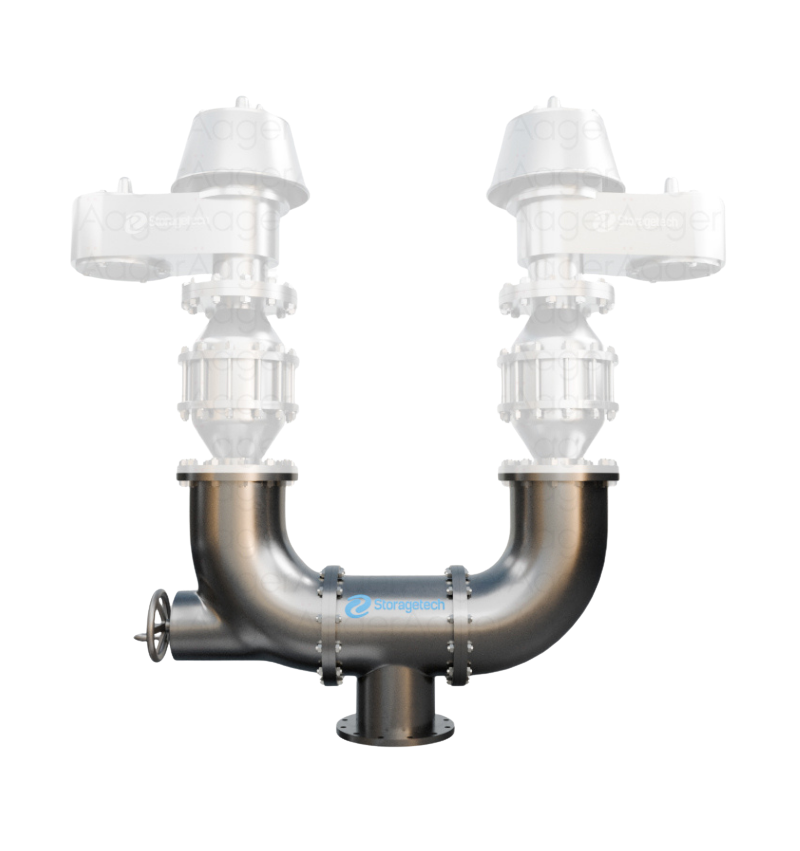

Storagetech™’s Model 330 Pressure Vacuum Relief Valve with Flame Arrestor provides protection to bulk storage tanks and vessels from over and under pressurization. The valves are mounted on the tank roof flange or a vent pipe from the vapour space. In the closed position the pressure relief pallet and diaphragm assembly is held tightly against a seal to prevent the loss of vapour to atmosphere. As the internal pressure in the tank increases, due to product filling and vapour development, the pressure in tank increases and in the event that the set pressure of the unit is reached, the diaphragm will open and discharge the gas to atmosphere. The opening set-point is selectable from a range between +61 mbar and +1000 mbar (+24 inch W.C. and 400 inch W.C.), and the valve will reseal when the tank returns to a safe pressure. In-line flame arrestor combination provides extra safety and avoid flame entrance inside the storage tank or pipe through valve openings. Flame arrestor can be unbolted and removed easily for maintanance purposes without effecting pressure vacuum relief valve function.

The Unit Will Comprise:

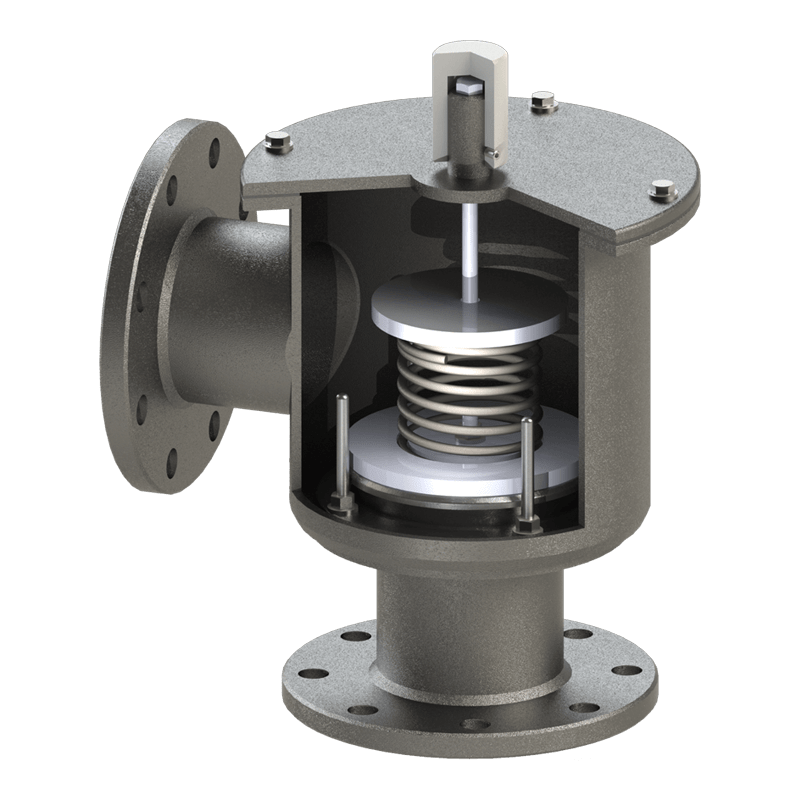

| Model 300 | In-line Deflagration Flame Arrestor (flanged) |

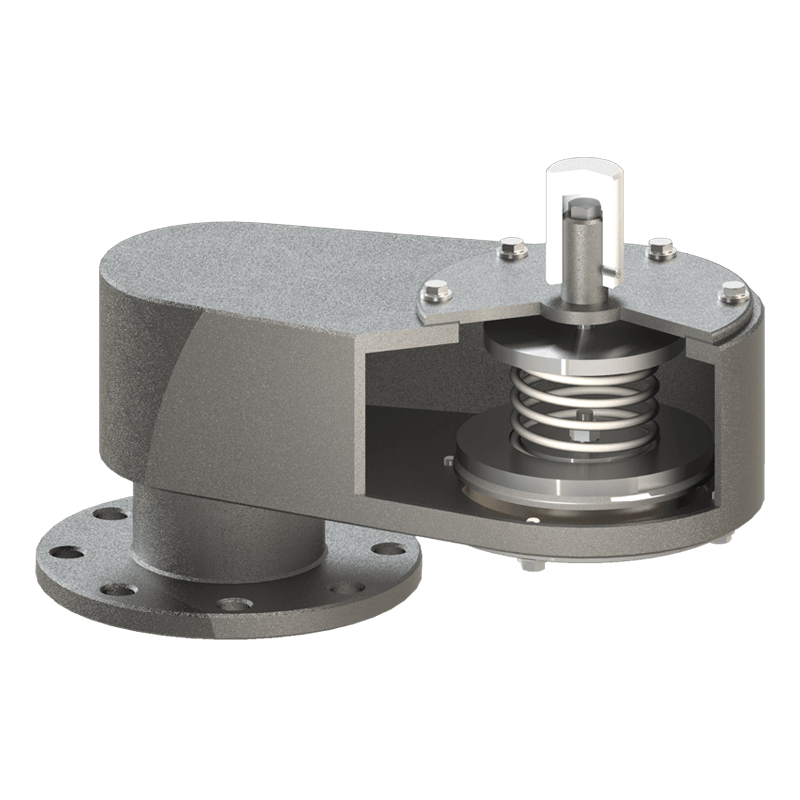

| Model 100 | Pressure-vacuum Relief Valve (weight-loaded; discharge to atmosphere) |

Design & Manufacturing Specifications

The size of the vent should be calculated in accordance with API Standard 2000 (ISO 28300) – Venting Atmospheric and Low-Pressure Storage Tanks or other international standards.