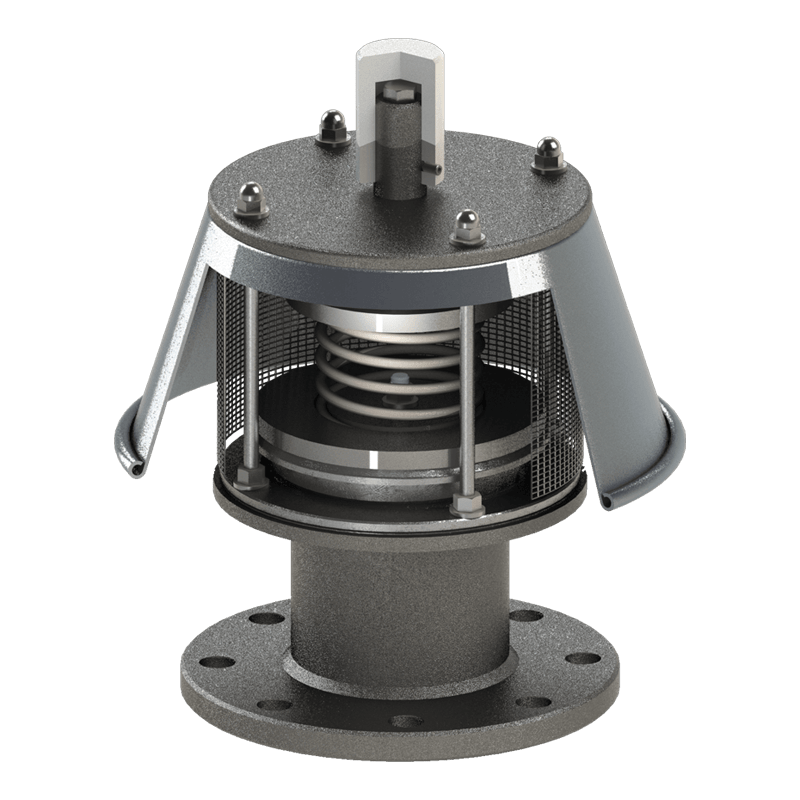

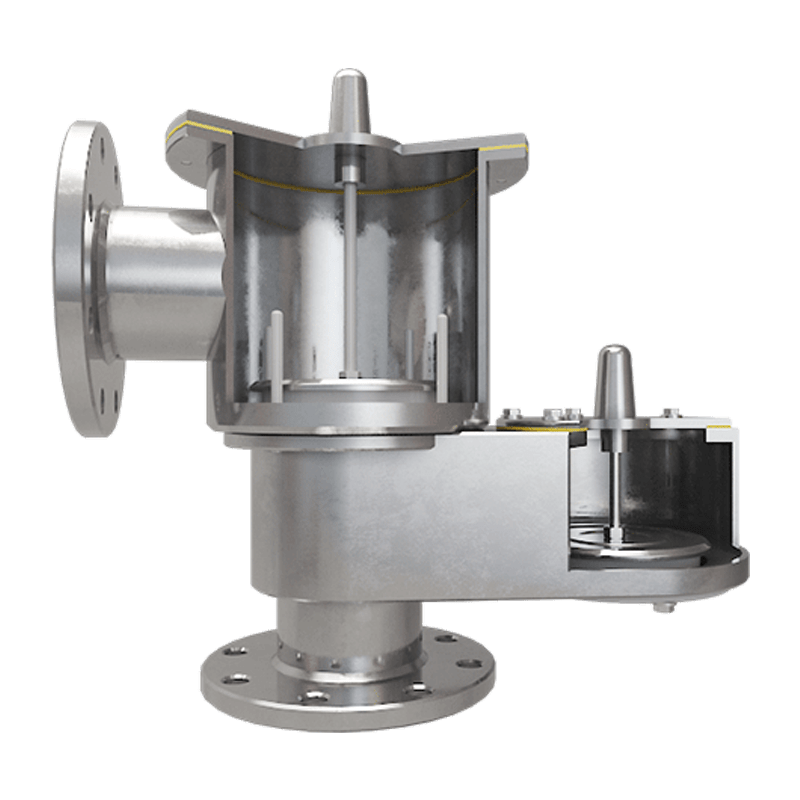

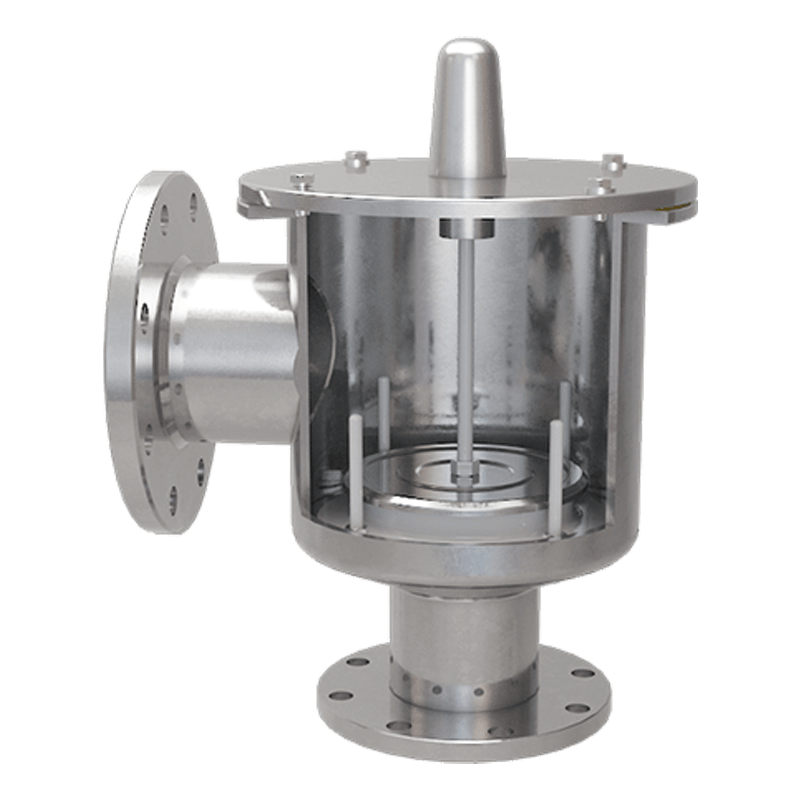

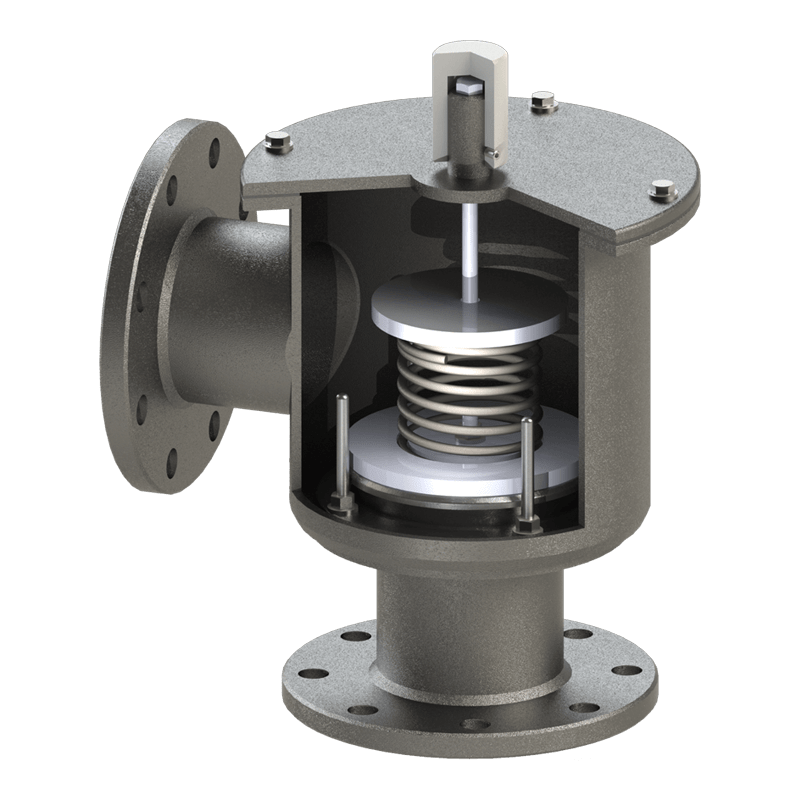

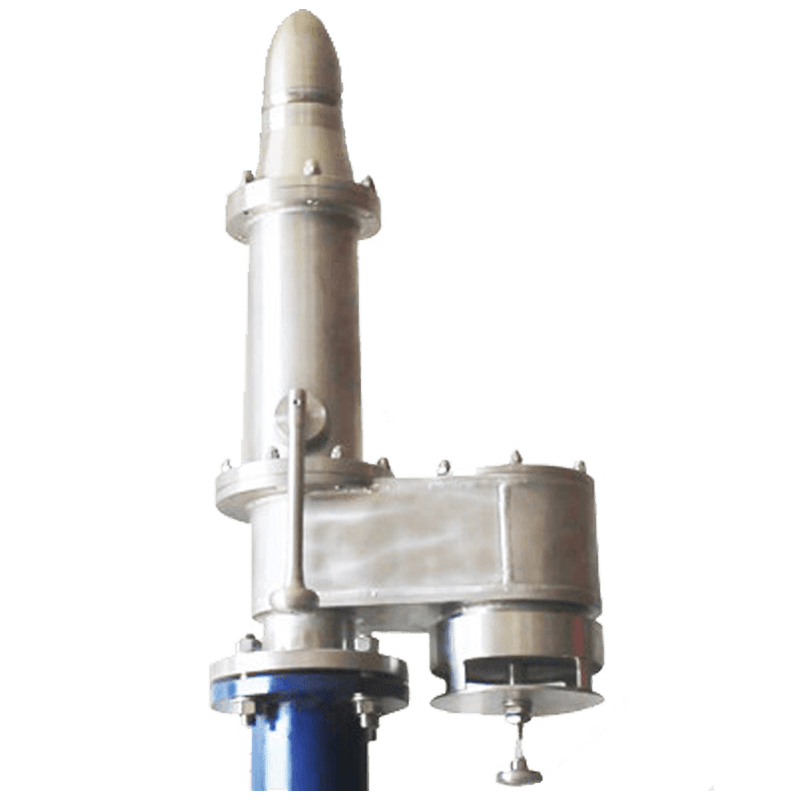

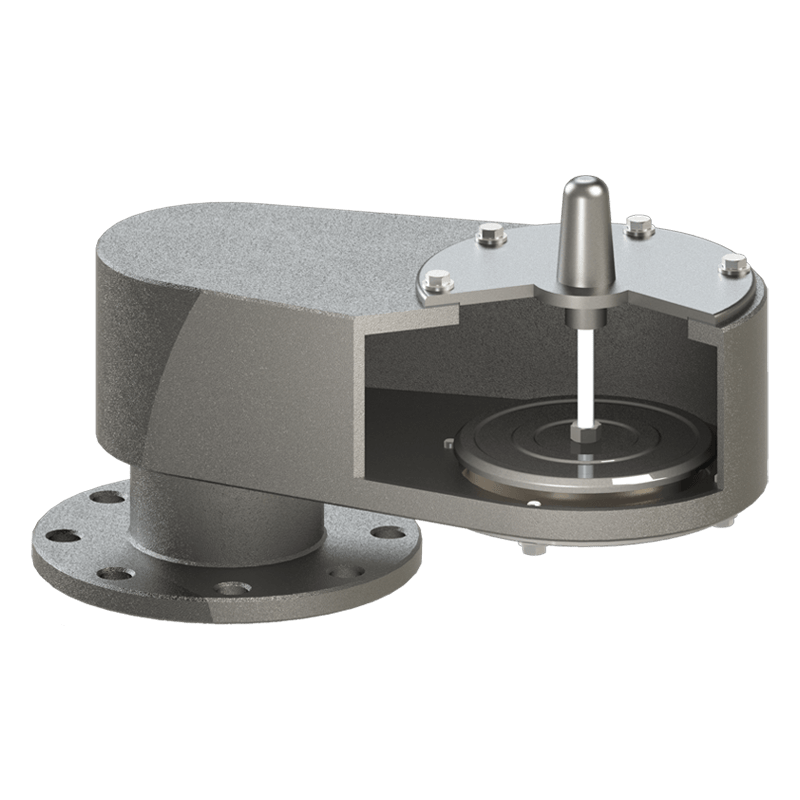

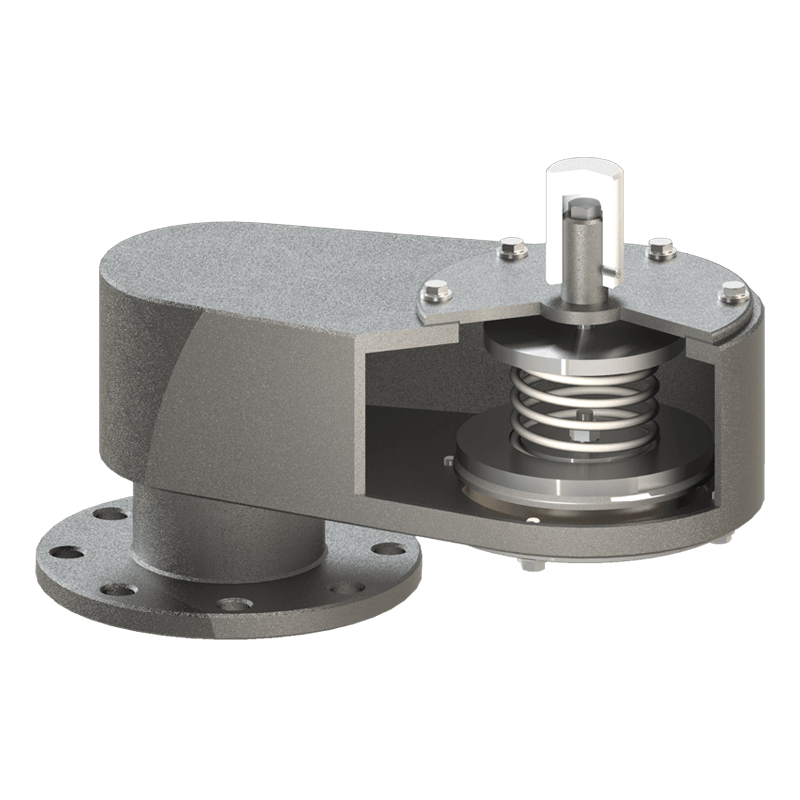

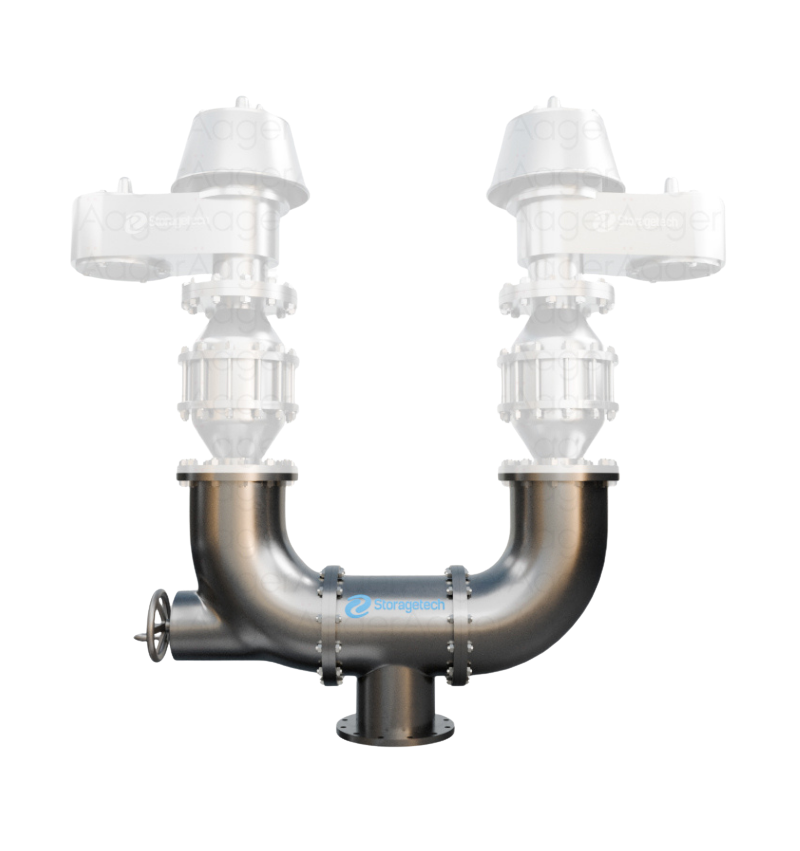

End of line, spring loaded

Model No: 143

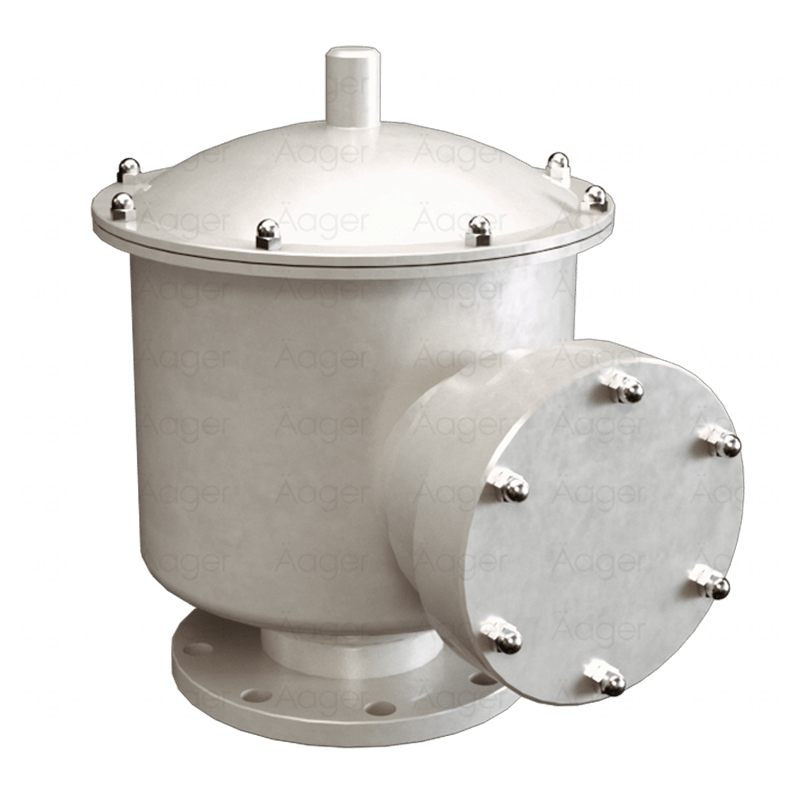

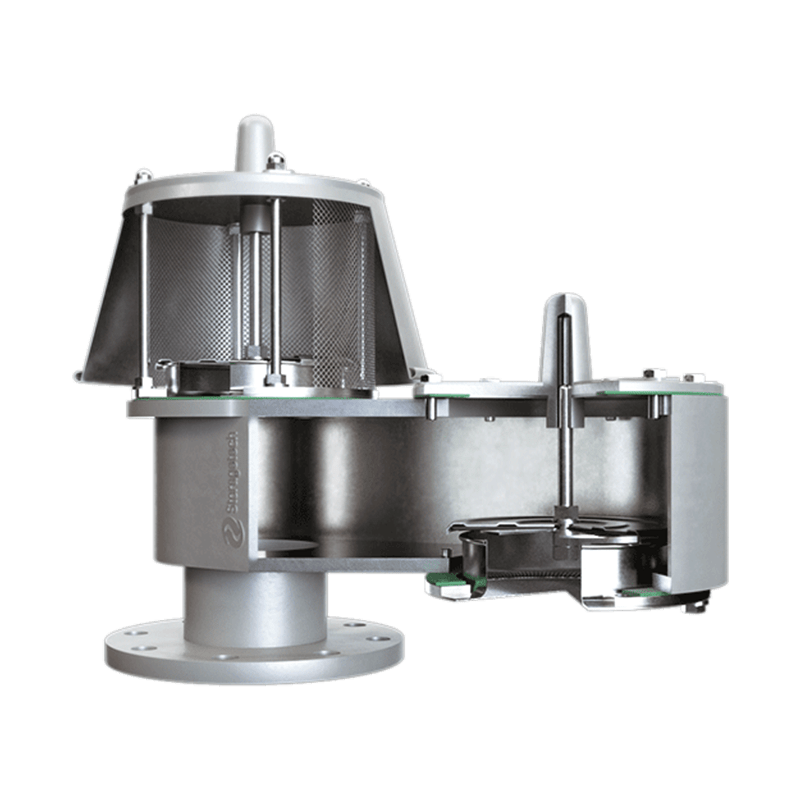

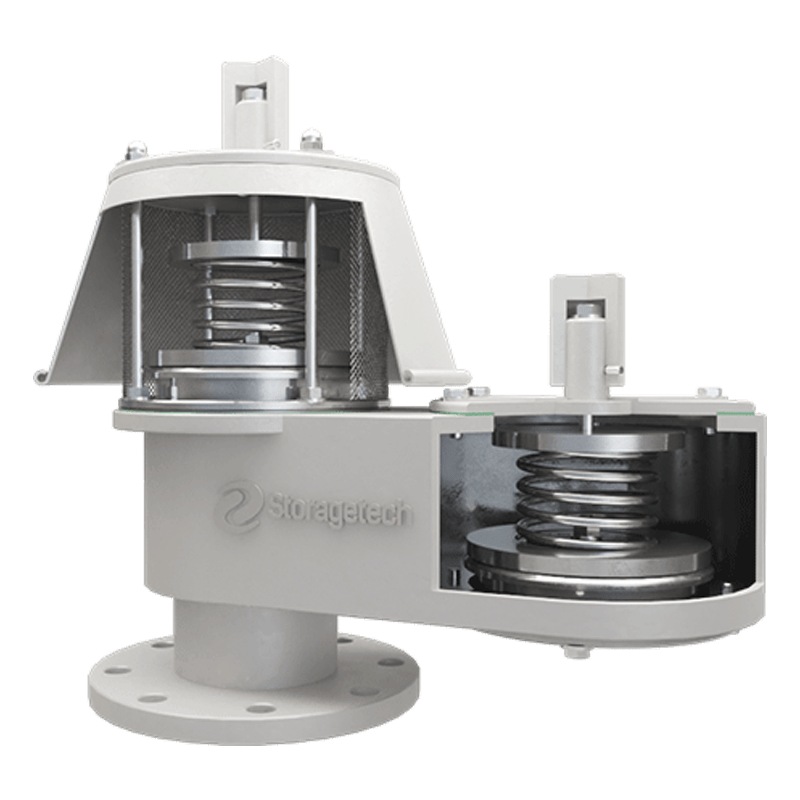

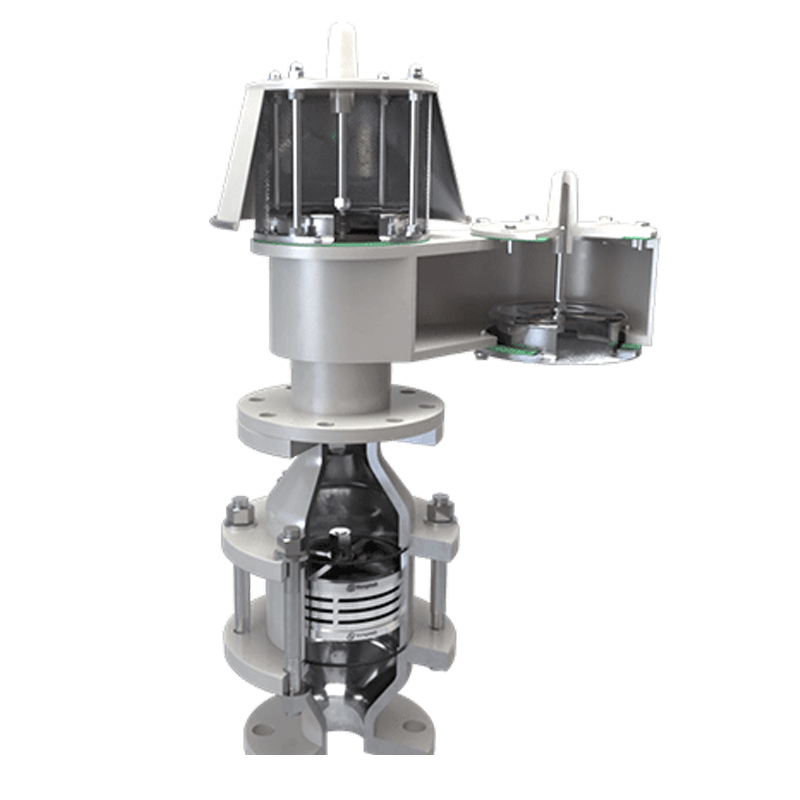

Designed for installation on bulk storage tanks, ERGIL Storagetech™’s Model 143 Pressure Relief Valve is designed to protect the tank from excessive internal pressure.

In the closed position the spring-loaded pallet and diaphragm assembly is held tightly against a seal to prevent the loss of vapour to atmosphere. As the internal pressure in the tank increases, due to product filling and vapour development, the pressure in tank increases and in the event that the set pressure of the unit is reached, the diaphragm will open and discharge the gas to atmosphere. The opening set-point is selectable from a range between +61 mbar and +1000 mbar (+24 inch W.C. and 400 inch W.C.), and the valve will close when the tank returns to a safe pressure.

The outlet port is protected by a weather hood and mesh guard to prevent ingress of debris that might obstruct the opening.

Setting Range

| Pressure: | Spring-loaded +61 mbar and +1000 mbar (+24 inch W.C. and +400 inch W.C.) |

| Ambient temp: | -20°C to +60°C |

Construction

| Standard sizes: | 2” to 12” 50 to 300mm |

| Flanges: | API Class 150 RF, DIN PN16 |

| Body: | Carbon steel, stainless steel, or aluminium |

| Seals: | Nitrile, Teflon, and Klingrit |

| Pallet: | Stainless steel AISI 304 |

| Springs: | Stainless steel |

| Paint finish: | Powder Coating, Colour RAL 9006, Epoxy Paint, Colour RAL 9006, Customer Specification |

| ATEX cert: | Ex II 1/2 G c IIB |

Design & Manufacturing Specifications

The integrity of the seal is tested for leakage in accordance with API Standard 2521 – Use of Pressure-Vacuum Vent Valves for Atmospheric Loss.

The size of the vent should be calculated in accordance with API Standard 2000 (ISO 28300) – Venting Atmospheric and Low-Pressure Storage Tanks or other international standards.