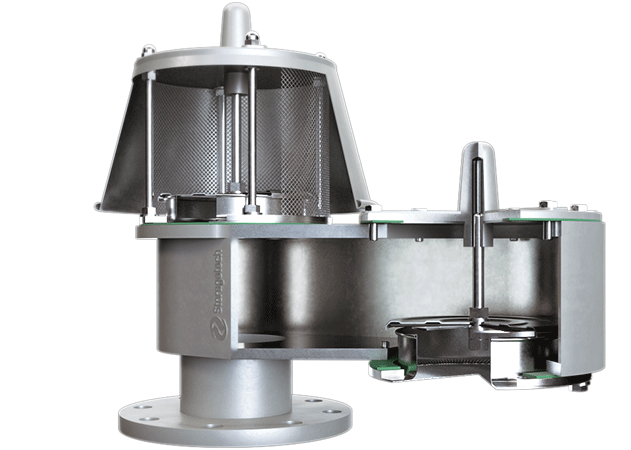

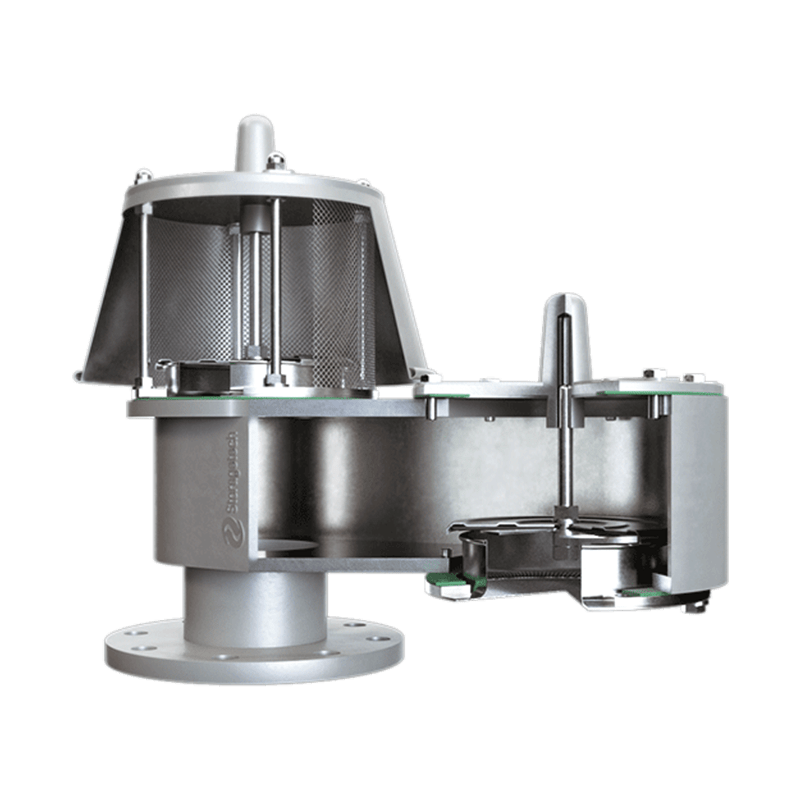

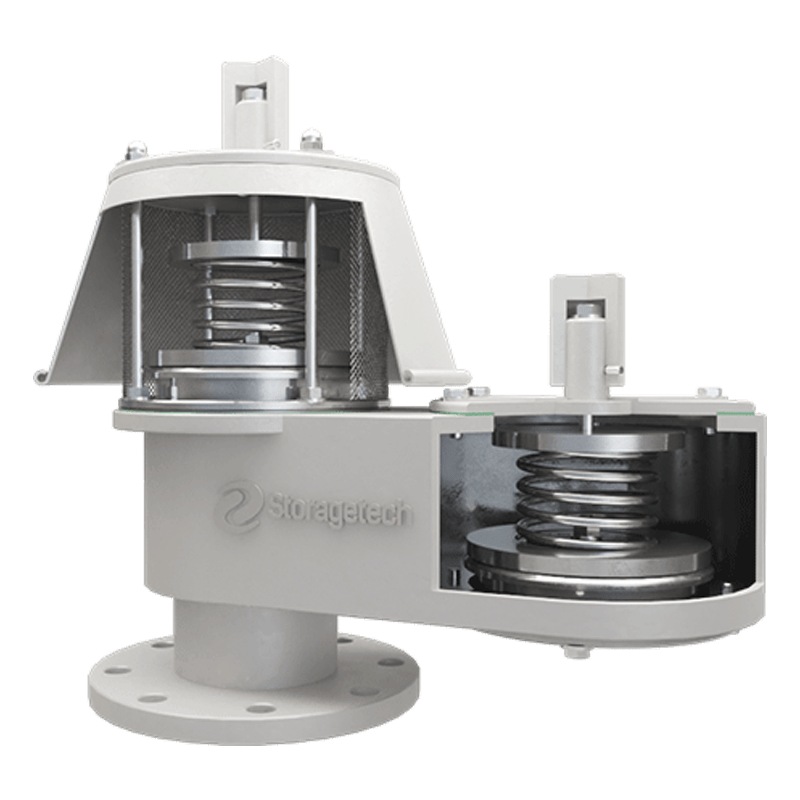

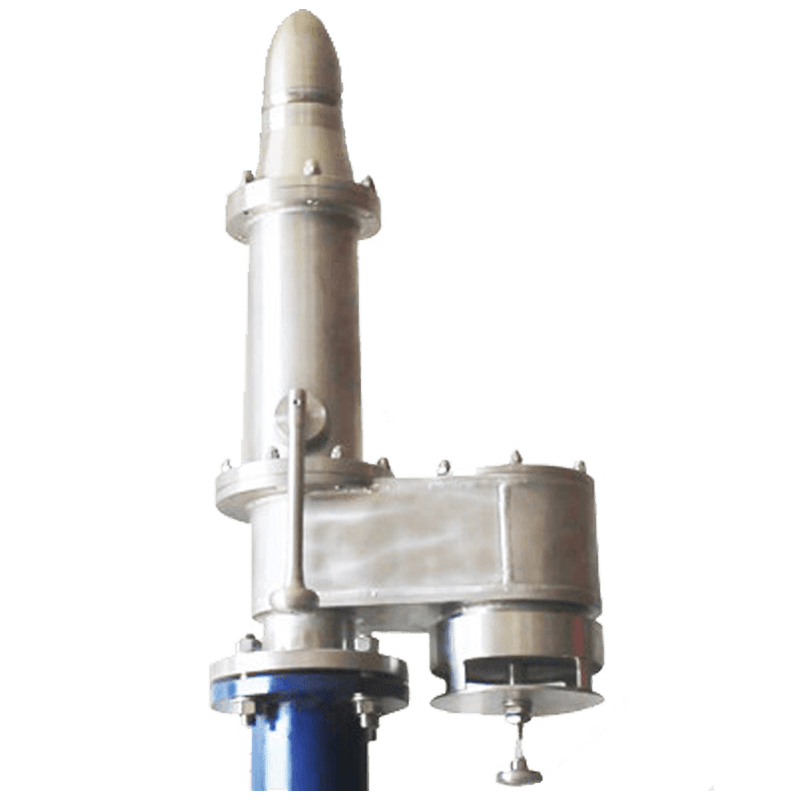

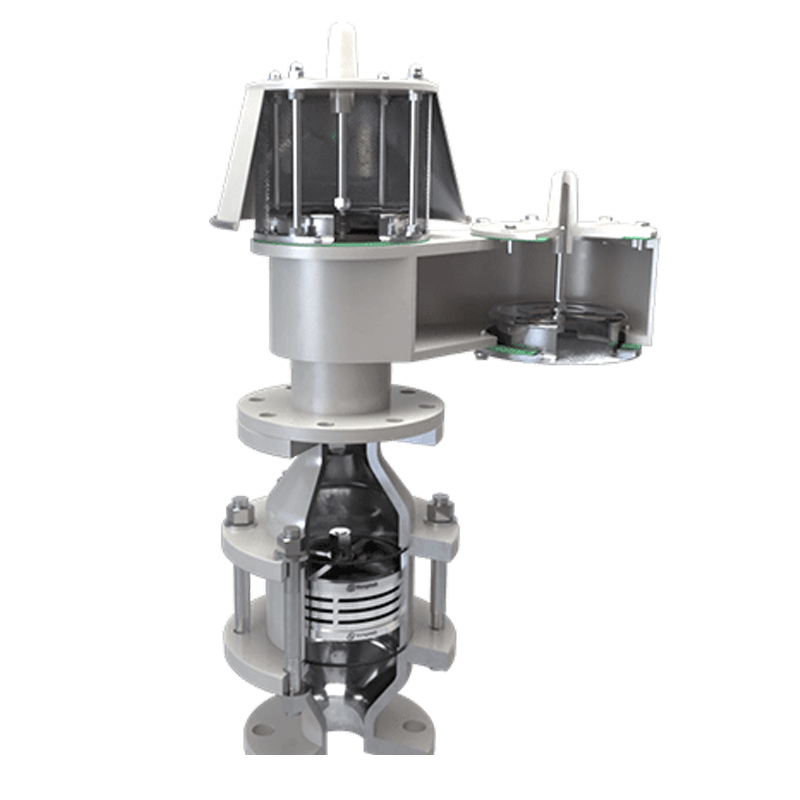

Top mounted, end-of-line, weight-loaded

Model No: 100

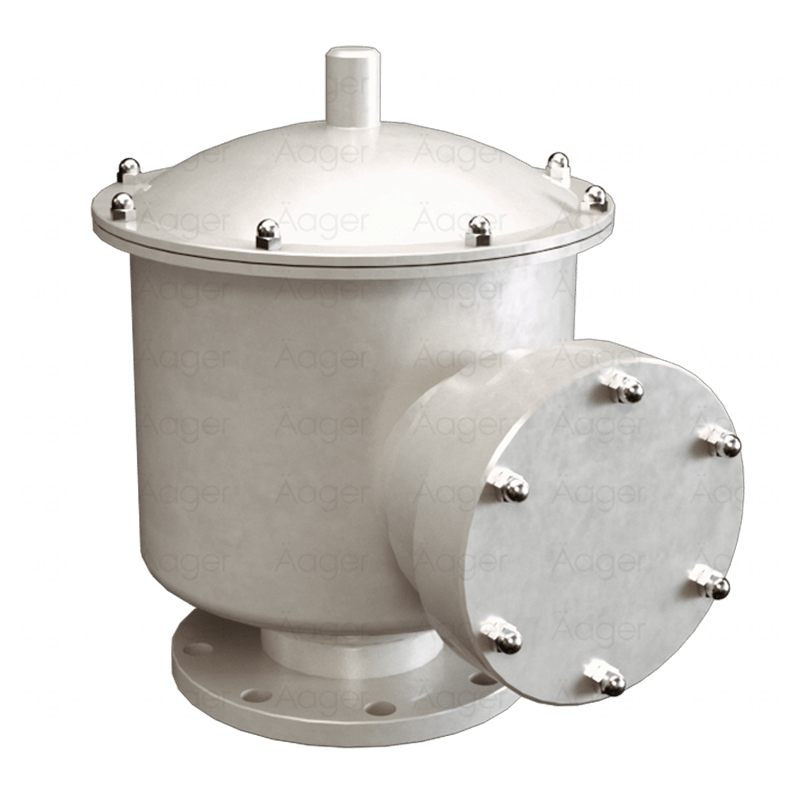

Storagetech™’s Model 100 Pressure Vacuum Relief Valve provides protection to bulk storage tanks and vessels from over and under pressurisation. The valves are mounted on the tank roof flange or a vent pipe from the vapour space.

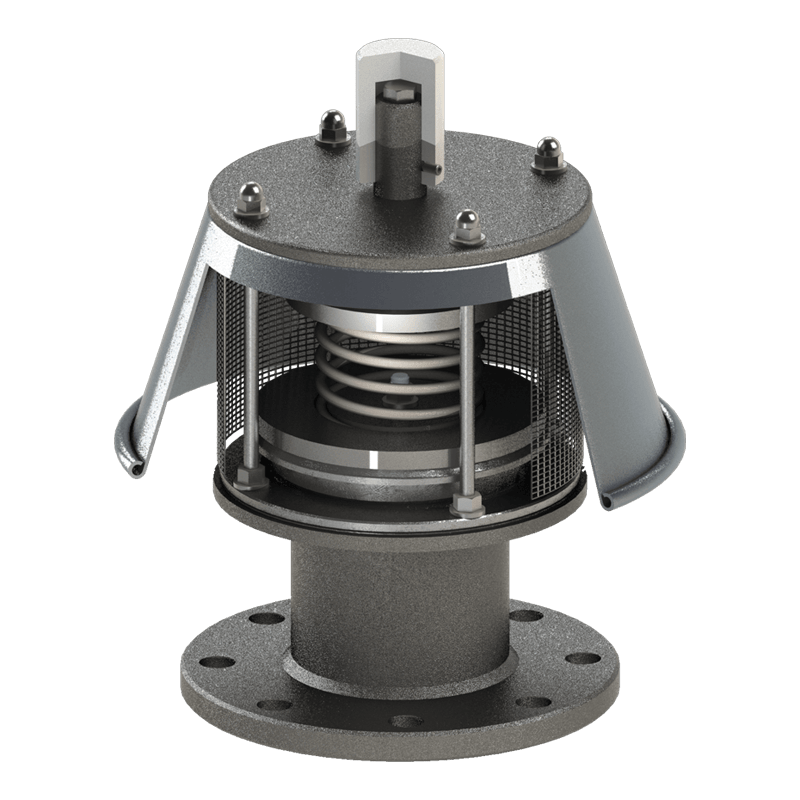

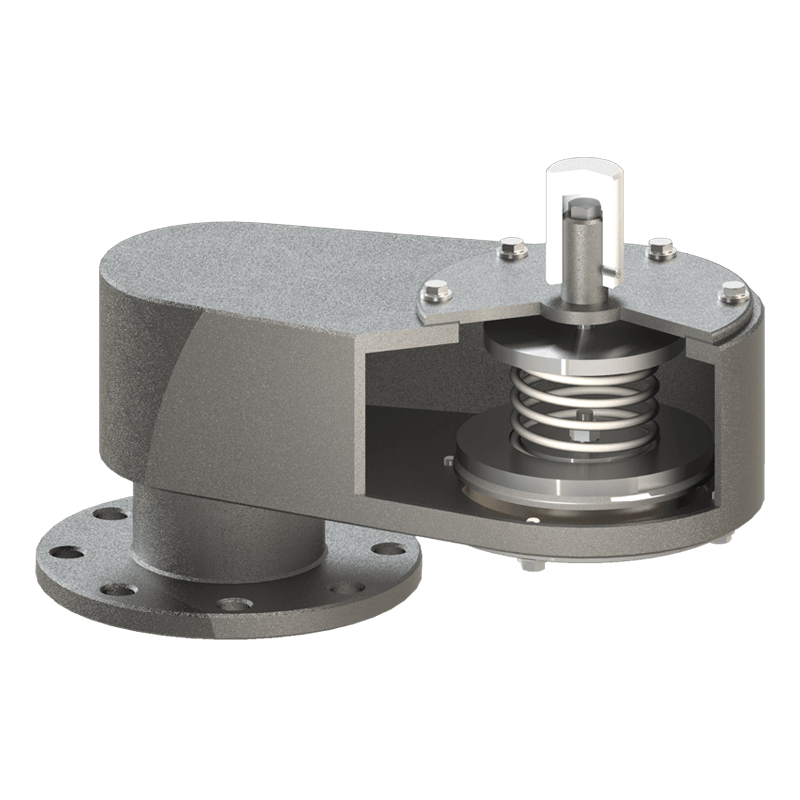

In the closed position the pressure relief pallet and diaphragm assembly is held tightly against a seal to prevent the loss of vapour to the atmosphere. As the internal pressure in the tank increases, due to product filling and vapour development, the pressure in tank increases and in the event that the set pressure of the unit is reached, the diaphragm will open and discharge the gas to the atmosphere. The opening set-point is selectable from a range +2.0 mbar and +60 mbar. (+0.8 inch W.C and +24 inch W.C), and the valve will reseal when the tank returns to a safe pressure.

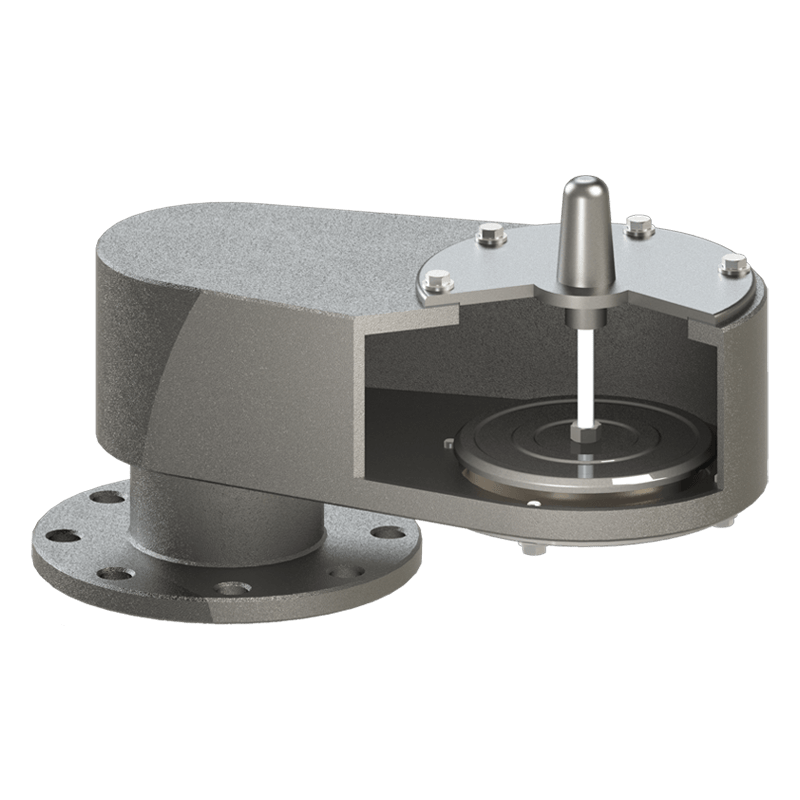

The vacuum pallet and diaphragm assembly is similarly maintained in the closed position. As the internal pressure in the tank reduces, due to emptying, the balance between the tank pressure and the external atmospheric pressure changes, and when the set pressure of the unit is reached, the diaphragm opens to admit air and rebalance the internal pressure. The vacuum set-point is selectable from a range between +2.0 mbar and +60 mbar. (+0.8 inch W.C and +24 inch W.C).The valve will reseal when the tank returns to a safe pressure.

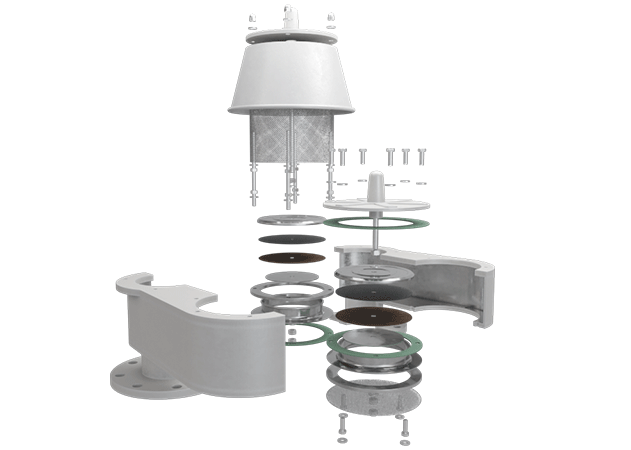

Several features are inherent in the valve design to ensure a smooth, positive and effective operation. The body is self-draining and drip rings prevent condensate from settling on seating surfaces. A diaphragm and seal manufactured from Teflon reduce the possibility of ice formation and sticky residues hindering the valve from opening, while the pallet assembly moves freely on guideposts. The outlet port is protected by a weather hood and mesh guard to prevent ingress of debris that might obstruct the opening, while a mesh filter screen in the vacuum inlet port performs the same function.