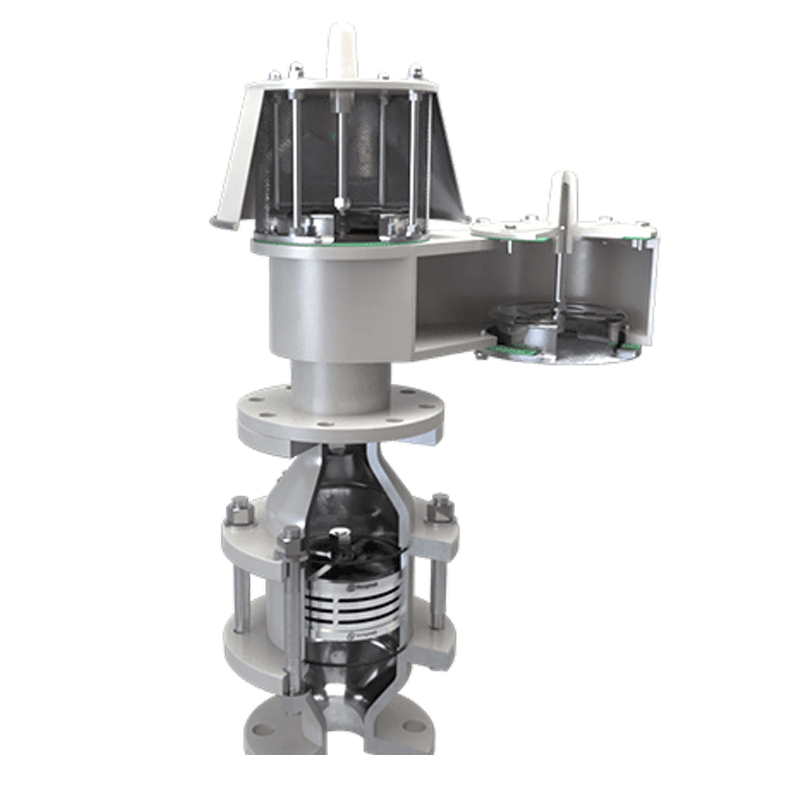

Vertical, In-line, Detonation

Model No: 320

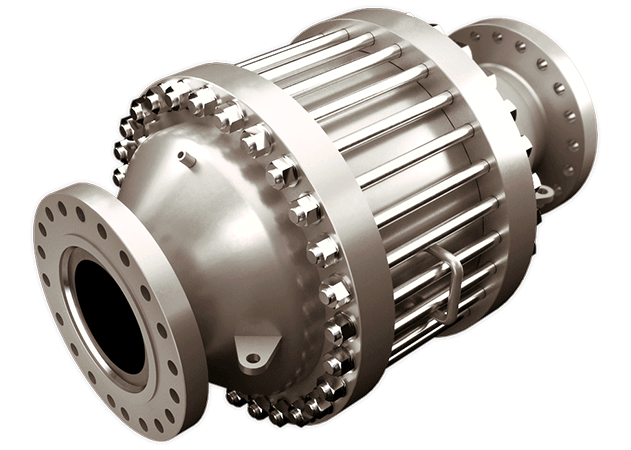

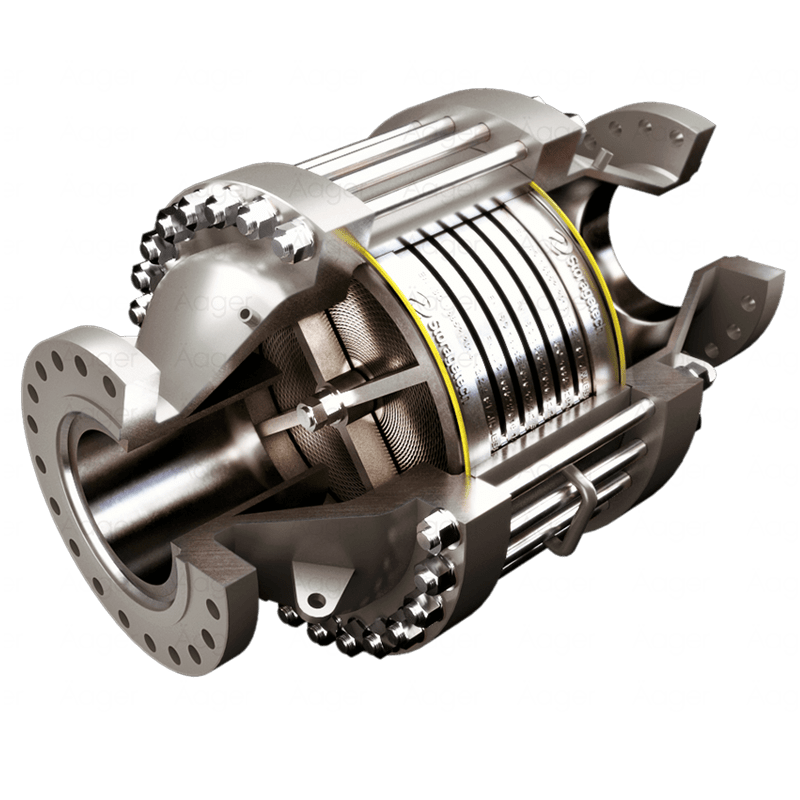

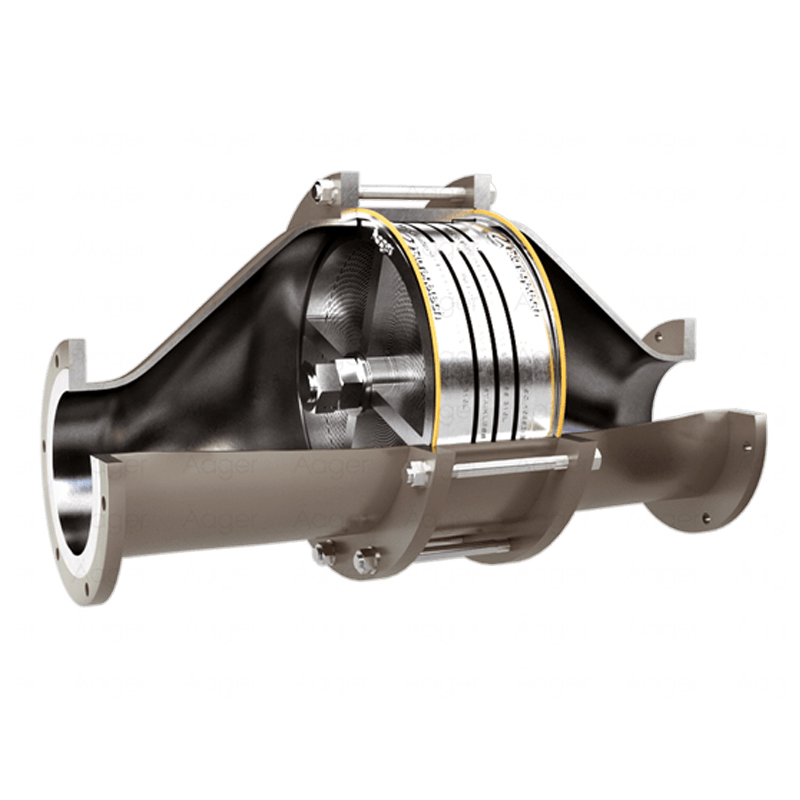

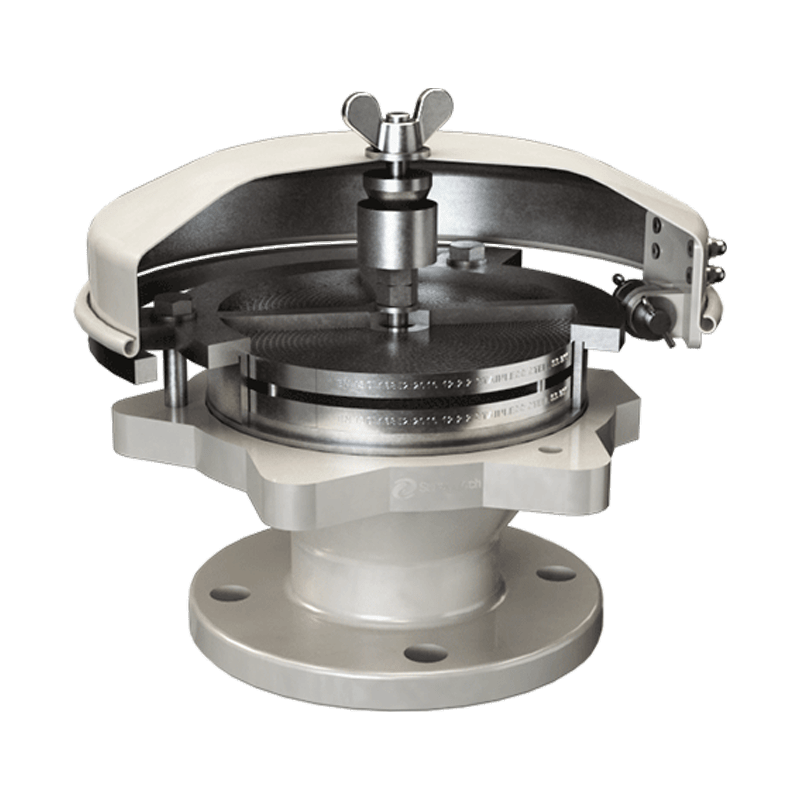

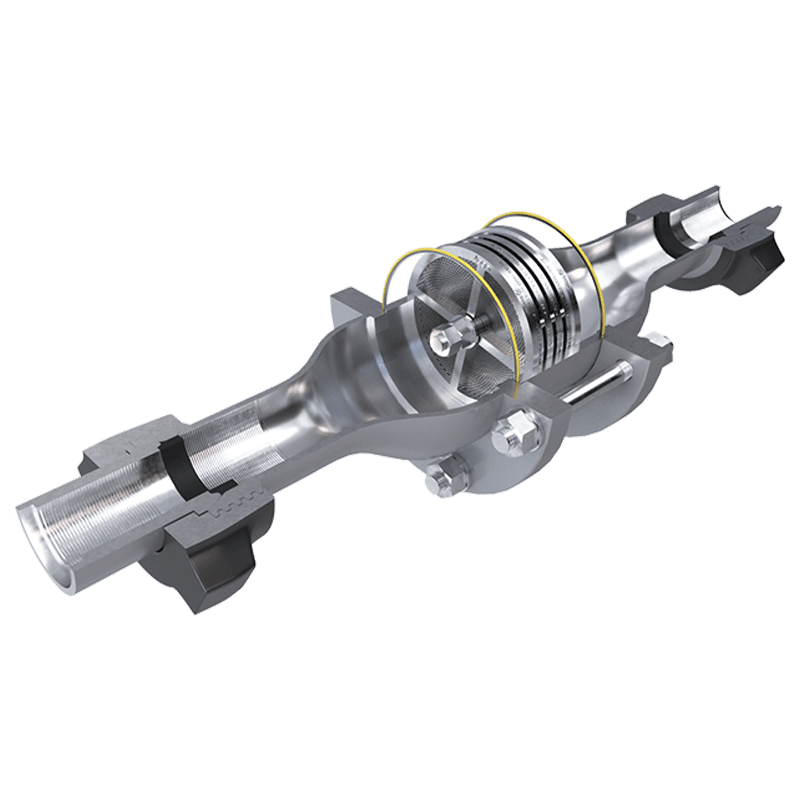

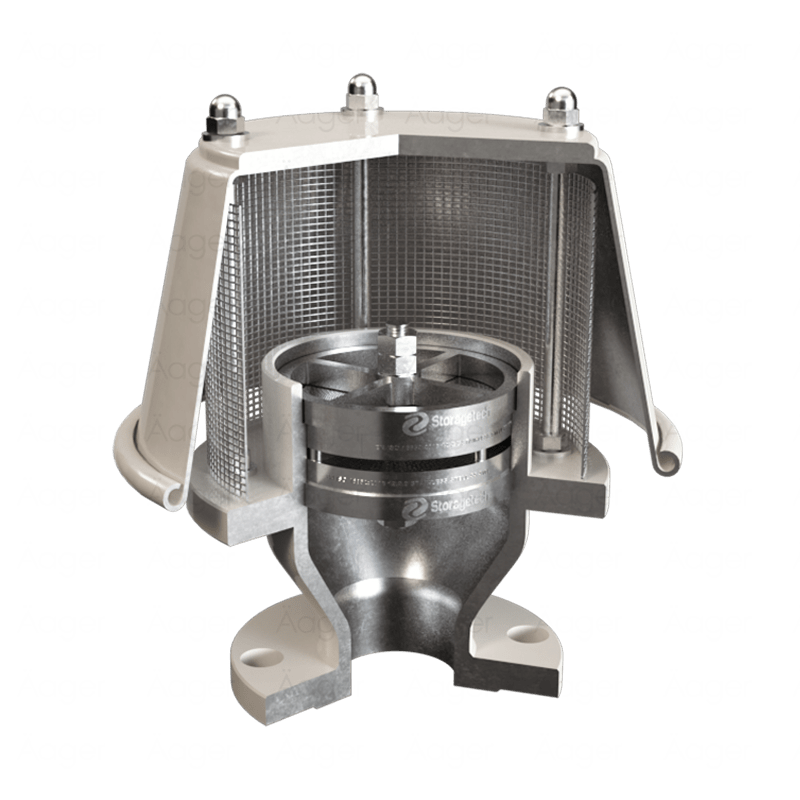

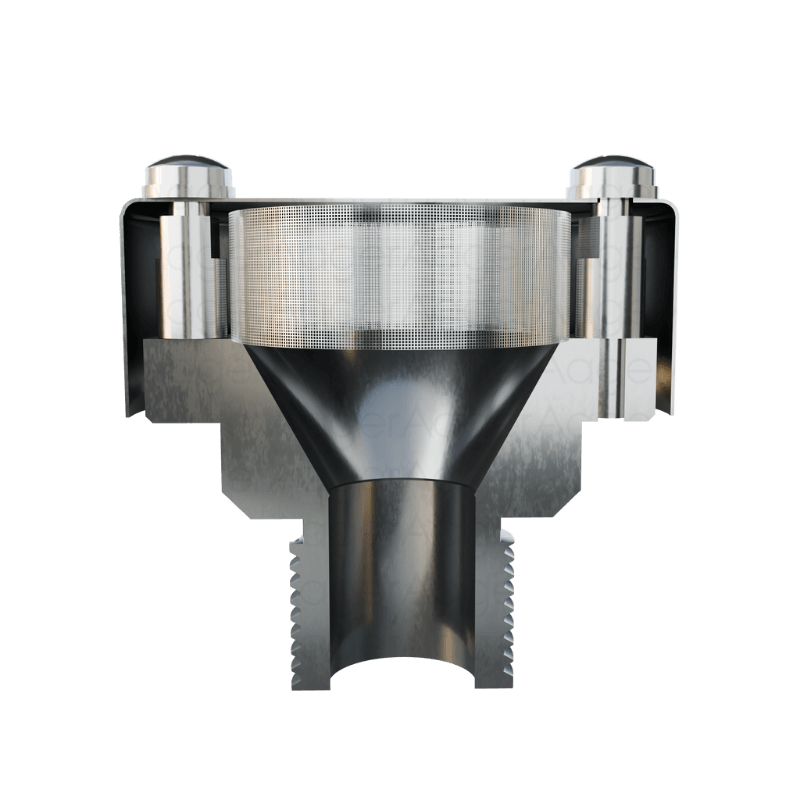

Storagetech™’s Model 320 In-line Detonation Flame Arrestor (also called flame arrestor or fire arrestor) is designed for installation in gas pipelines. Detonation occurs when a flame travelling through the pipeline reaches supersonic velocities, usually as a result of the pipeline configuration or pipeline surface roughness. Changes in gas density and pressure causes the flame velocity to metamorphose from subsonic to supersonic.

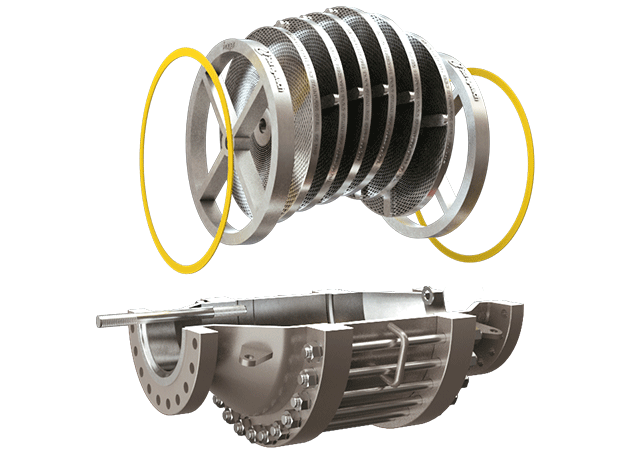

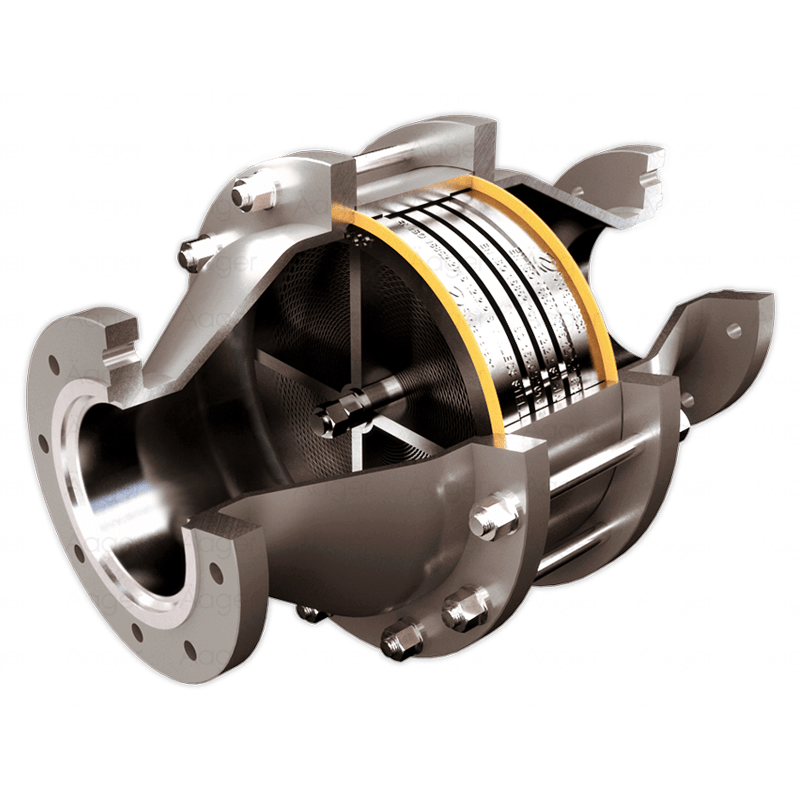

The flame quenching element is designed to be three or four times the area of the pipe in which it is installed, and is assembled between two flanged reducing spools. The element comprises a tightly rolled scroll or scrolls of crimped stainless steel ribbon to form passages through which the vapour passes. The area of each passage determines level of protection that the element provides. Storagetech™’s Model 320 In-line Detonation Flame Arrestor has a maximum experimental safe gap (MESG) as per the standard, and is suitable for gas groups IIB and IIA.

Construction

| Standard sizes: | 1” to 12” DN25 to DN300 |

| Body / Flanges: | Carbon steel, Stainless steel AISI 316 –L or 304-L, Aluminium, Customer Specification |

| Flange drilling: | API Class 150, PN16, and Special |

| Flame element: | Stainless steel AISI 316 –L or 304-L |

| O-ring seal: | Nitrile, Special |

| Screen: | Stainless steel |

| Weather hood: | Carbon steel, Stainless steel or Aluminium |

| Paint finish: | Powder Coating, Colour RAL 9006, Epoxy Paint, Colour RAL 9006, Customer Specification |

| ATEX cert: | Ex II 1/2 G IIB |

Design & Manufacturing Specifications

The size of the vent should be calculated in accordance with API Standard 2000 (ISO 28300) – Venting Atmospheric and Low-Pressure Storage Tanks or other international standards.