February

2026

Dear Readers,

Welcome to our the second newsletter of 2026! Wishing a year filled with peace for the world. In this February 2026 issue, we’ve gathered the latest updates about our company. We hope you enjoy staying informed!

Webinar: Aluminum Flat Roof Systems

Looking to enhance safety, durability, and long-term performance? Join our webinar and learn how Aluminum Flat Roof Systems deliver measurable value.

Date: 05 February 2026 – Time: 14:00 (GMT+3) – Language: English

Featuring our experts: 🔹 HASAN SARIOĞLU – R&D Manager, Mechanical Engineer 🔹 Derya Koca – R&D Specialist, PHD Chemist

In tank farms, a flame arrestor is a “silent” device—until the moment it’s tested

This video shows why low-quality, look-alike flame arresters are dangerous: they may look acceptable, but under a real flame event they can fail structurally, allowing flame propagation and escalating to a tank fire within seconds.

A flame arrestor is not a place to save cost. Specify engineered protection.

#ProcessSafety #TankFarms #FlameArrestor #HSE #AssetIntegrity #Engineering

New Ergil.com Website Launch

We’re excited to announce the launch of our newly redesigned website: ergil.com.

Built with a cleaner interface, improved navigation, and a more streamlined experience across devices, the new site makes it easier to explore our capabilities, learn about our work, and connect with our team.

Visit the new website: ergil.com We look forward to sharing more news and insights here. #WebsiteLaunch #DigitalExperience #BrandRefresh

High-Pressure Pig Launcher & Receiver for NNPC / TotalEnergies Development Project in Nigeria

ERGIL has successfully completed the engineering, manufacturing, and delivery of a high-pressure Pig Launcher & Receiver package for a major NNPC / TotalEnergies oil & gas development project in Nigeria.

Designed for 240 bar(g) and manufactured in compliance with ASME Section VIII Div.2, the system features an ERGIL-designed quick opening closure with mechanical interlocking, ensuring maximum operational safety for intelligent pigging under extreme conditions.

This project further strengthens ERGIL’s footprint in Nigeria and highlights our expertise in high-pressure, safety-critical pipeline equipment.

#ERGIL #NNPC #TotalEnergies #PigLauncher #HighPressure #ASME #OilAndGas #EngineeringExcellence

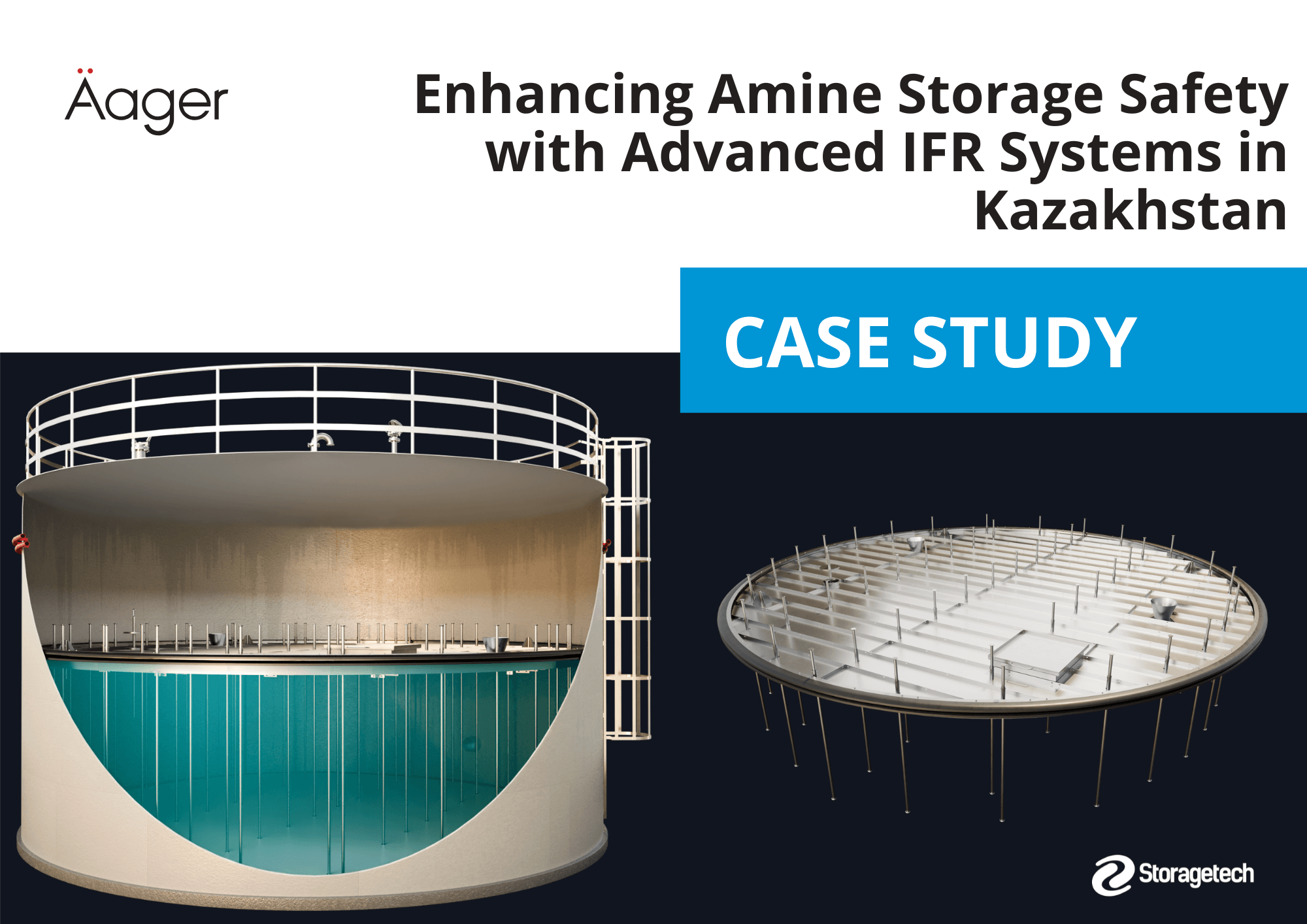

Proud to share a look into the manufacturing of an Advanced Gas-to-Gas Sulfur Condenser Project delivered for TÜPRAŞ İzmir Refinery 🇹🇷

Designed and manufactured in compliance with ASME, TEMA Class “R”, PED, CE, and NACE standards, this project reflects ERGIL’s expertise in refinery-grade heat transfer equipment and high-integrity sulfur service applications.

Read more about the project: https://ergil.com/advanced-gas-to-gas-sulfur-condenser-project-for-tupras-izmir-refinery/

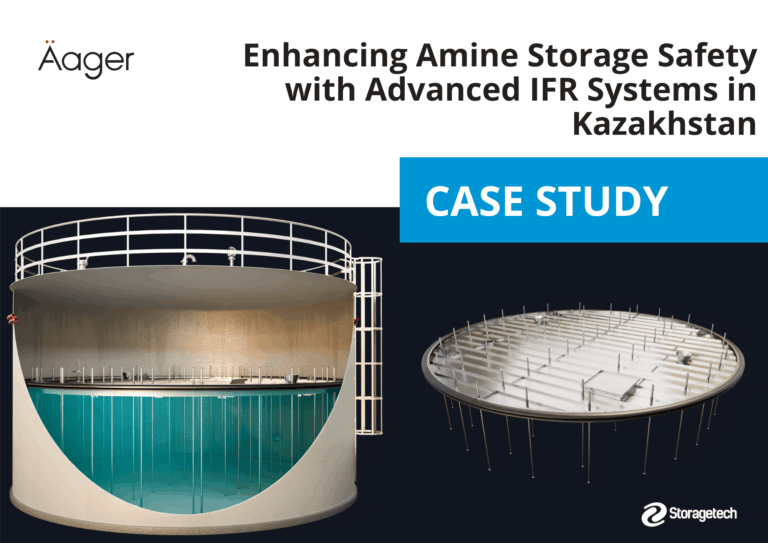

Enhancing Amine Storage Safety with Advanced IFR Systems in Kazakhstan

We are proud to support a reputable operator in Kazakhstan with a new full-contact Internal Floating Roof (IFR) solution for amine storage.

By replacing a problematic pontoon-type IFR with our Megafloat full-contact system and advanced mechanical seal design, we helped:

- Eliminate roof tilting and sinking risks

- Reduce emissions and product losses

- Strengthen compliance with stringent environmental regulations

This project demonstrates how the right IFR technology can significantly enhance safety, reliability, and sustainability in critical storage applications.

👉 Discover the full case study and key lessons learned from the project. https://storagetech.de/enhancing-amine-storage-safety-with-advanced-ifr-systems-in-kazakhstan/

January

2026

Dear Readers,

Welcome to our the first newsletter of 2026! Wishing a year filled with peace for the world. In this January 2026 issue, we’ve gathered the latest updates about our company. We hope you enjoy staying informed!

Farewell 2025, Welcome 2026! ✨

On Friday, December 26, 2025, we celebrated the end of the year with a wonderful event at our company. Accompanied by delicious food and energizing music, we came together to leave behind the year’s fatigue and share the excitement of the new year ahead.

During this special evening, we presented gifts to our team members who made a difference with their dedication and contributions, and enjoyed the happiness of celebrating a productive and successful year together.

We step into 2026 with hope, energy, and new goals! Here’s to achieving many more successes together… #Team #Celebration #CompanyCulture #NewYear2026 #TogetherWeGrow

Getting Ready for UltraFacility Austin

Before UltraFacility Austin opens today, our team completed the booth setup and preparations.Seeing the space come together reminded us of what we do every day:turning empty floors into fully engineered modular systems for advanced industrial and semiconductor facilities.

At Ergil we design and fabricate:

- Modular process skids

- Pressure vessels and rubber/GRP-lined tanks

- Scrubbers and filtration systems

- Carbon-capture modules

- Steel structures and sludge-handling units.

We look forward to meeting industry partners and visitors over the next few days and sharing how our modular fabrication capabilities support faster, cleaner, and more reliable project delivery. #ultrafacility #semiconductor #modularconstruction #pressurevessels #cleantech #watertechnology #carboncapture #texasmanufacturing #modularskids

A Strong Start at UltraFacility Austin

A strong first day at UltraFacility Austin — thank you to everyone who stopped by our booth.

Across our conversations, one challenge came up repeatedly:semiconductor fabs need faster, more reliable construction of critical water and utility systems.

This is exactly where ERGIL adds value. Our modular approach enables:

- Fast-delivery process skids (UPW, wastewater, chemical systems)

- Pressure vessels & GRP/rubber-lined tanks

- Scrubbers, filtration units, and steel structures

All engineered and fabricated in our certified, automated, solar-powered facility — reducing onsite labor, improving quality, and accelerating project schedules. Looking forward to Day 2 and more great discussions. #semiconductor #ultrafacility #modularfabrication #processskids #pressurevessels #watertreatment #industrialengineering

Thank You for a Great Week at UltraFacility Austin

As UltraFacility Austin comes to a close, we’d like to extend a sincere thank you to all the visitors who spent time with us this week.

The semiconductor industry is growing rapidly, and so are its construction challenges — tight schedules, complex utilities, and labor shortages.Our modular fabrication approach is engineered to help solve exactly these issues.

We appreciated every conversation and look forward to continuing the dialogue with new partners and collaborators.

Ergil’s engineered Carbon Capture System is now on video

In this short animation, we walk through how our modular CCS solution captures CO₂ from industrial flue gas, regenerates solvent efficiently, and delivers purified CO₂ for storage or utilization – supporting our customers’ decarbonization and ESG roadmaps.

From power and petrochemicals to cement and heavy industry, Ergil designs and manufactures custom carbon capture systems that integrate seamlessly into existing facilities with a compact, skid-based layout. Watch the video to see how the process works step by step and get in touch with our team to discuss your next CCUS project.

We are pleased to announce another successful pipeline pigging package delivered by ERGIL

Designed and manufactured in our certified facility, this system will support safe and efficient pipeline cleaning, inspection and maintenance, helping to protect asset integrity and minimise operational downtime. Many thanks to our customer for their trust in our engineering and fabrication capabilities.

#ERGIL #Aager #PigLauncher #PigReceiver #PigSignaller #Pipeline #OilAndGas #Engineering #Safety #Quality

DNV-Approved Welding Capabilities at ERGIL

We are pleased to announce that ERGIL has received the Welding Workshop Approval Certificate from DNV.

Our Mersin (MTOSB) facility is now approved under DNVGL-CP-0352 for the manufacture of welded products in the following ranges:

- Hull structures

- Hull equipment

- Machinery components

This approval confirms that our welding procedures, personnel qualifications and quality system meet DNV’s stringent international requirements — ensuring safety, quality and full compliance for our customers in the energy, oil & gas, petrochemical and marine industries.

If you are looking for a certified partner for high-integrity welded equipment and process solutions, our team is ready to support your next project.

#ERGIL #Aager #DNV #Welding #Fabrication #PressureVessels #StorageTanks #OilAndGas #Energy #Quality #Safety #Compliance

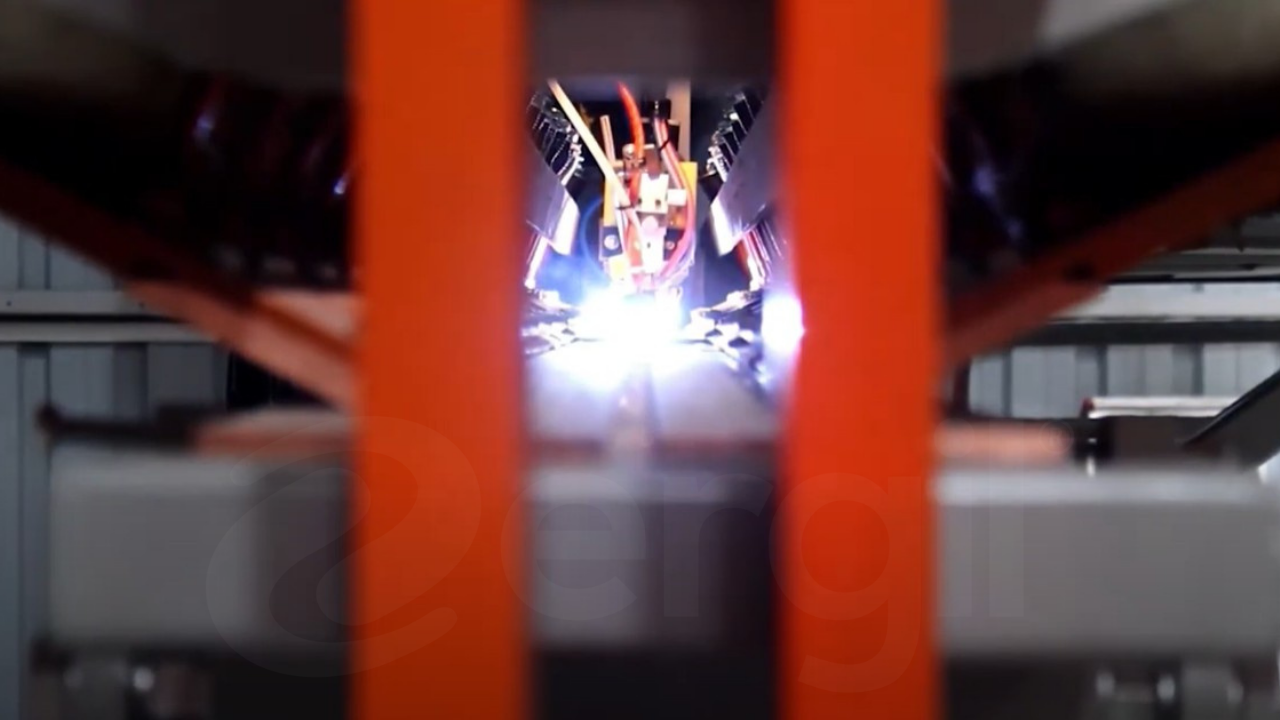

IFR Delivery for TOTAL Energies in Equatorial Guinea

Storagetech has successfully delivered two internal floating roof (IFR) systems for TOTAL Energies’ new storage terminal in Equatorial Guinea.

We supplied full-contact carbon-steel IFRs with Storagetech primary and secondary mechanical seals, together with a complete tank-top equipment package, to help reduce vapor losses and support local environmental regulations.

By combining our tank design and equipment manufacturing capabilities, we provided a single engineered solution that improves reliability and simplifies project execution for the client. #ERGIL #Storagetech #TotalEnergies #IFR #FloatingRoof #TankSafety #EmissionControl

A Safer, Cleaner IFR Solution for Amine Storage in Kazakhstan

We are proud to support a reputable operator in Kazakhstan with a new full-contact Internal Floating Roof (IFR) solution for amine storage.

By replacing a problematic pontoon-type IFR with our Megafloat full-contact system and advanced mechanical seal design, we helped:

Eliminate roof tilting and sinking risks

Reduce emissions and product losses

Strengthen compliance with stringent environmental regulations

This project demonstrates how the right IFR technology can significantly enhance safety, reliability, and sustainability in critical storage applications.

👉 Discover the full case study and key lessons learned from the project. https://storagetech.de/enhancing-amine-storage-safety-with-advanced-ifr-systems-in-kazakhstan/