Navigating the Changes in ASME Sec. VIII Div.1 2023 Edition for Pressure Vessels and QOC

The American Society of Mechanical Engineers (ASME) continuously revises its standards to adapt to the evolving landscape of technology and material science. The 2023 edition of ASME Sec. VIII Div.1, a cornerstone in the design and construction of pressure vessels, introduces pivotal changes. These modifications reflect a commitment to safety, efficiency, and innovation in pressure vessel technology.

Materials and Design Advancements

One of the most significant areas of change in the 2023 edition is the introduction of new material standards. These changes not only accommodate emerging materials in the industry but also revise existing criteria to improve the safety and longevity of pressure vessels. The updates in design criteria are particularly noteworthy, as they consider environmental factors and the latest understanding of material behaviors under stress.

- Enhanced Material Standards:

- Introduction of New Materials: The 2023 edition includes provisions for new materials that have been developed since the last revision. This takes into account the latest advancements in metallurgy and composite materials, offering more options for pressure vessel construction.

- Revised Material Specifications: Existing material specifications have been updated to align with current industry practices and technological advancements. These revisions address factors like corrosion resistance, toughness at low temperatures, and long-term durability under operational stresses.

- Allowable Stress Values: The standard has revised allowable stress values for materials. This revision considers extensive research on how different materials behave under stress over time, including factors like creep, fatigue, and stress rupture.

- Updated Design Criteria:

- Fatigue Analysis: Enhanced guidelines for fatigue analysis are introduced to ensure that vessels can withstand cyclic loading conditions over their operational life. This includes considerations for thermal expansion, pressure cycles, and other dynamic loading scenarios.

- Environmental and Operational Factors: The new edition includes design criteria that account for environmental and operational factors such as temperature variations, exposure to corrosive environments, and external stresses.

- Safety Factors and Design Margins: Safety factors and design margins have been re-evaluated to ensure that pressure vessels maintain structural integrity under worst-case scenarios. This reassessment helps in enhancing the overall safety and reliability of the vessel.

- Use of Advanced Simulation Techniques: The 2023 edition acknowledges the role of advanced simulation techniques in design. It integrates guidelines for using computational tools for stress analysis, helping designers to optimize vessel design for both performance and safety

- Impact on Pressure Vessel Design and Construction:

- Broader Material Choices: With new materials included, designers and manufacturers have a broader range of options to choose from, allowing for more tailored and efficient vessel designs.

- Increased Durability and Safety: The updated material specifications and design criteria aim to increase the durability and safety of pressure vessels, potentially reducing maintenance needs and enhancing operational reliability.

- Compliance and Certification Challenges: Manufacturers and designers may face challenges in adapting to these new standards, requiring updates to their design processes and potentially retraining staff to ensure compliance.

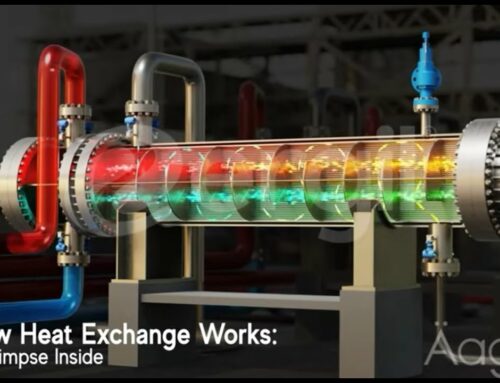

Fabrication and Inspection Overhaul

The 2023 edition brings to light advanced fabrication processes, marking a step towards more efficient and quality-oriented manufacturing. Additionally, the updated inspection methodologies, including enhanced NDE techniques, underscore the importance of maintaining the integrity and quality of pressure vessels. These changes aim to ensure that each vessel meets the highest standards from inception to completion.

Focus on Quality of Construction (QOC)

Quality of Construction (QOC) receives significant attention in this edition. The ASME has introduced stricter guidelines for manufacturing, testing, and documentation, emphasizing the quality at each construction stage. This focus ensures that the end product not only complies with the standards but also sets a benchmark in reliability and safety.

- Fabrication Processes: The 2023 edition introduces advanced fabrication processes, promoting efficiency and quality in manufacturing. These processes are aligned with the latest technological advancements in the industry.

- Inspection Methodologies: Enhanced inspection methodologies, including sophisticated NDE techniques, are introduced. These are aimed at ensuring the integrity of pressure vessels throughout their lifecycle.

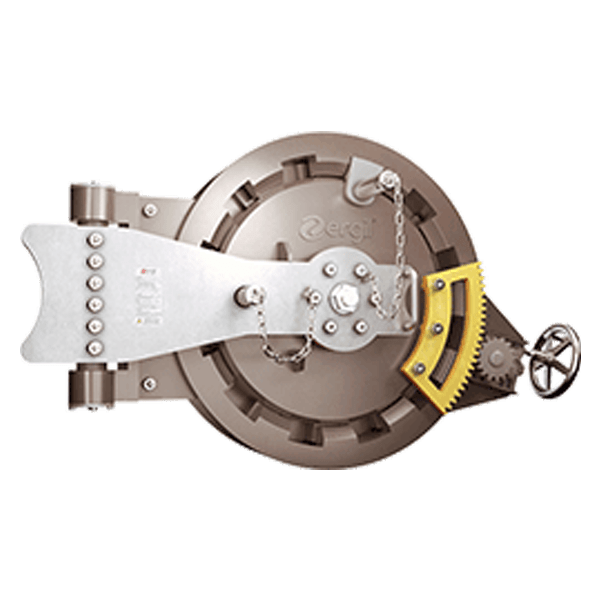

Testing and Welding Procedures

The new edition brings in refined pressure testing methods, ensuring that each vessel can withstand its operating conditions. Moreover, the introduction of modern welding techniques aligns with the properties of advanced materials used in current vessel fabrication. These changes are indicative of ASME’s forward-looking approach to standardizing construction practices in line with technological advances.

- Pressure Testing Methods: The updates include refined pressure testing methods to validate vessel integrity under various operating conditions.

- Welding Techniques: The introduction of advanced welding techniques is aligned with modern material properties, ensuring strong and reliable vessel construction.

Compliance and Certification Adjustments

To streamline the transition to these new standards, ASME has revised the processes for certification and compliance. The updated guidelines provide clarity for manufacturers and inspectors, ensuring a smooth adaptation to the new standards while maintaining the integrity of the certification process.

Certification Processes: The edition outlines revised processes for obtaining ASME certification, with clear guidelines for manufacturers and inspectors to ensure compliance with the updated requirements.

Transition Guidelines: The document provides guidelines for a smooth transition to the new standards, ensuring minimal disruption to existing operations.

Industry Implications and Conclusion

The changes in the ASME Sec. VIII Div.1 2023 Edition signify a major shift in the industry’s approach to designing and constructing pressure vessels. These revisions demand that professionals update their practices and knowledge to align with the new standards. Ultimately, the 2023 edition strengthens the commitment to advancing industry standards, mirroring the growth in technology and material science.

Compliance with these changes is not just regulatory adherence; it is an essential step toward upholding the highest standards of safety and quality in pressure vessel design and construction. As the industry adapts to these changes, it paves the way for a future where innovation and safety go hand in hand.