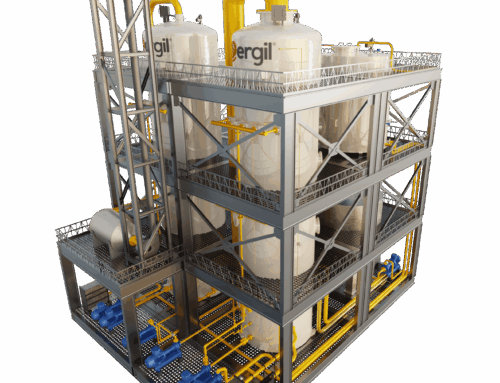

08.02.2018, Mersin, Türkiye – Äager Storagetech™ is an ATEX certified designer and manufacturer with extensive experience providing technologically advanced flame arrestors & storage tank valves for oil, gas, petrochemical, chemical, pharmaceutical, agro, water, waste water treatment, and utility industries, successfully received ATEX directive 94/9/EC Certificate deflagration type end-of-line flame arrestors series from 2 inch to 8 inch which is approved to EN ISO 16852:

What is an End-of-line Flame Arrestor?

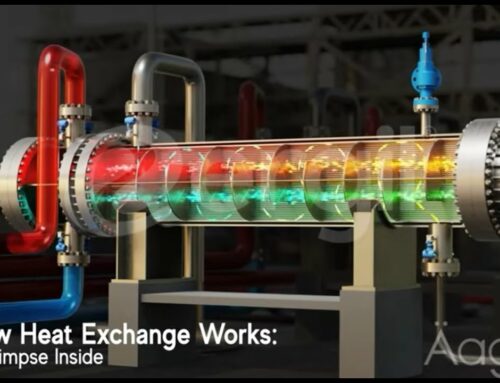

This type of flame arrestor is installed on low-pressure storage processing tanks, bleed tanks, or other waste gas devices. Normally, they are installed on a vent nozzle mounted on a tank that is discharged directly into the atmosphere. They can also be incorporated as integral parts of conservation vents installed on atmospheric storage tanks containing flammable liquids. The gases produced by vaporization of many flammable liquids have similar flame speeds when mixed with air. Typical of these are gasoline, jet fuel, benzene, plastics monomers, and organic solvents. Often the pressure drop across the vent valve of a conservation vent is the ¾ inch (17mm) of water or more. In this case, the velocity of the gas flow through the vent-valve opening will be higher than the speed at which the flame can propagate upstream through the opening.

What is special about Äager Storagetech End-of-line Flame Arrestor?

New model end-of-line endurance burning flame arrestors are equipped with a quick opening hood that automatically opens after certain time under continuous fire to release the gas freely without blocking or changing the direction.

Äager Storagetech™ operates accredited management systems to guarantee its flame arrestor products are manufactured in accordance with international standards, and to maintain quality and materials traceability which leads to customer satisfaction and products that function safely. These include ISO 9001:2008 – Quality management systems, ISO 14001:2004 – Environmental management systems, and OHSAS 18001:2007 – Manual for occupational health and safety system. Engineering standards in place include the ASME U-Stamp Boiler and Pressure Vessel Certification, CE marking, and ATEX certification relating to Directive 94/9/EC – Equipment and protective systems intended for use in potentially explosive atmospheres.

The new model end-of-line is ready at your service to provide a safe, quick, and economical solution for your industrial applications.